Top 10 PCB Prototype Suppliers for Your Manufacturing Needs

By:Admin

Established in {}, Pcb Prototype Supplier has always been committed to providing innovative and reliable PCB prototypes for businesses across various sectors, including telecommunications, automotive, aerospace, and consumer electronics. With a focus on quality, precision, and efficiency, the company has established itself as a trusted partner for businesses seeking cutting-edge PCB solutions.

As part of their ongoing efforts to expand their offerings and reach new markets, Pcb Prototype Supplier has partnered with {} to bring their advanced PCB prototyping capabilities to a wider audience. By leveraging their expertise in PCB design, manufacturing, and assembly, Pcb Prototype Supplier aims to support the diverse needs of {} and its clients, offering tailored solutions that enhance product development and time-to-market.

The collaboration between Pcb Prototype Supplier and {} represents a significant milestone for both organizations, as it combines their respective strengths to deliver comprehensive PCB solutions to a global customer base. By tapping into Pcb Prototype Supplier’s advanced facilities, state-of-the-art equipment, and skilled workforce, {} can effectively address the growing demand for high-quality PCB prototypes with quick turnaround times.

“Partnering with {} is a testament to our commitment to delivering exceptional PCB solutions to a wider audience,” said [Spokesperson], [Title] at Pcb Prototype Supplier. “Through this collaboration, we are confident that we can provide {} and its clients with the innovative and reliable PCB prototypes they need to succeed in today’s competitive market.”

With a steadfast focus on quality and customer satisfaction, Pcb Prototype Supplier is renowned for their industry-leading PCB prototyping services, which are backed by stringent quality control measures and adherence to international standards. By aligning with {}, Pcb Prototype Supplier aims to reinforce their position as a preferred PCB supplier, offering a diverse range of prototyping options to meet the unique requirements of various industries.

“Pcb Prototype Supplier’s expertise and dedication to excellence make them an ideal partner for us,” said [Spokesperson], [Title] at {}. “We are pleased to collaborate with Pcb Prototype Supplier to enhance our PCB prototyping capabilities, enabling us to deliver top-notch solutions to our clients and propel their businesses forward.”

As the demand for high-quality PCB prototypes continues to rise, Pcb Prototype Supplier remains steadfast in their mission to provide cutting-edge solutions that empower businesses to innovate and thrive in a dynamic market. Through their collaboration with {}, Pcb Prototype Supplier is poised to further solidify their standing as a premier provider of advanced PCB prototypes, delivering unmatched value and performance to their customers.

With a shared commitment to excellence, innovation, and customer satisfaction, the partnership between Pcb Prototype Supplier and {} is poised to make a significant impact in the PCB manufacturing industry. By harnessing their collective expertise and resources, both companies are well-positioned to address the evolving needs of businesses worldwide, driving progress and success in an increasingly competitive landscape.

Company News & Blog

Industry News: High Volume Production Factory Increases Output to Meet Growing Demand

High Volume Production Factory Expands Operations to Meet Growing Demand With the global market demand for electronic devices and consumer goods on the rise, the High Volume Production Factory is expanding its operations to meet the increasing need for mass production. The factory, which specializes in the manufacturing of high-quality electronic products, has seen a substantial increase in demand for its services, prompting the decision to expand and optimize its production capabilities.The High Volume Production Factory, located in [location], has been a key player in the electronics manufacturing industry for over a decade. The company has built a solid reputation for delivering top-notch products with a focus on quality, efficiency, and innovation. With state-of-the-art facilities and a team of highly skilled professionals, the factory has consistently met the needs of its clients, establishing itself as a trusted partner for businesses looking to bring their products to market.The decision to expand the factory's operations comes as a response to the growing demand for electronic devices and consumer goods worldwide. As technology continues to evolve and new products enter the market, the need for high-volume production has become increasingly important for businesses looking to stay competitive. The High Volume Production Factory is committed to meeting this demand and ensuring that its clients have access to the resources and capabilities they need to succeed.The expansion plans for the factory include the addition of new production lines, increased warehouse space, and the implementation of advanced manufacturing technologies. By investing in these enhancements, the company aims to improve its production efficiency, reduce lead times, and meet the growing demand for high-quality electronic products. Additionally, the factory will be hiring new staff members and providing training and development opportunities to ensure that its workforce is prepared to handle the increased production volume.In a statement regarding the expansion, [company CEO] expressed enthusiasm about the future of the factory and its ability to meet the needs of its clients. "As the demand for electronic products continues to grow, we are excited to expand our operations and enhance our capabilities to better serve our clients," said [CEO]. "We are committed to delivering top-quality products and ensuring that our clients have the resources they need to bring their products to market. This expansion represents a significant step forward for our company and we look forward to the positive impact it will have on our business and the industry as a whole."The High Volume Production Factory's expansion plans have already attracted attention from potential clients in the electronics industry. With the promise of increased production capacity and improved efficiency, the factory is well-positioned to meet the needs of businesses looking to scale up their operations and bring their products to market. Additionally, the company's commitment to quality and excellence has solidified its reputation as a leading provider of high-volume production services.As the global demand for electronic products continues to grow, the High Volume Production Factory is poised to play a key role in meeting this need. With a focus on innovation, efficiency, and quality, the factory is well-prepared to expand its operations and provide businesses with the resources they need to succeed in a competitive market. The company's dedication to delivering top-notch products and its commitment to meeting the evolving needs of its clients make it a valuable partner for businesses looking to thrive in the electronics industry.

Top Bonding Factories for Gold Ribbon Manufacturing

Gold Ribbon Bonding Factories is a leading manufacturer in the bonding industry, specialising in the production of high-quality adhesive products. With a strong commitment to research and development, the company has established a reputation for innovation and excellence in the market.Founded in 1995, Gold Ribbon Bonding Factories has grown to become a trusted name in the bonding industry. The company has a strong focus on quality and reliability, and its products are used in a wide range of applications, including automotive, construction, electronics, and packaging.The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for efficient production and consistent quality control. Gold Ribbon Bonding Factories is committed to sustainability and environmental responsibility, and has implemented environmentally-friendly practices across its operations.One of the key strengths of Gold Ribbon Bonding Factories is its dedicated team of professionals. The company employs a highly-skilled workforce with expertise in chemistry, engineering, and material science. This team is committed to delivering innovative solutions and superior customer service, and plays a crucial role in the company's success.Gold Ribbon Bonding Factories operates with a customer-centric approach, and works closely with clients to understand their specific needs and requirements. The company offers customised solutions to meet the unique demands of each customer, and prides itself on delivering superior products and service.In addition to its manufacturing capabilities, Gold Ribbon Bonding Factories also offers comprehensive technical support and consultancy services. The company's team of experts provides guidance on product selection, application methods, and troubleshooting, ensuring that customers achieve optimal results with Gold Ribbon Bonding Factories' products.The company's commitment to innovation is evident in its continuous investment in research and development. Gold Ribbon Bonding Factories is constantly exploring new materials, technologies, and processes to stay ahead of market trends and meet evolving customer needs.Gold Ribbon Bonding Factories takes pride in its adherence to the highest quality standards. The company is certified to ISO 9001 and ISO 14001, demonstrating its commitment to quality management and environmental responsibility. This certification ensures that Gold Ribbon Bonding Factories' products are manufactured to the highest standards of quality and safety.The company's dedication to excellence has earned it a strong reputation in the market, and Gold Ribbon Bonding Factories is widely regarded as a reliable and trusted partner. Its products are used by leading companies across various industries, and the company has built long-lasting relationships with its customers based on mutual trust and satisfaction.Moving forward, Gold Ribbon Bonding Factories is poised for further growth and success. The company continues to invest in research and development, expand its product range, and explore new market opportunities. With its strong focus on quality, innovation, and customer satisfaction, Gold Ribbon Bonding Factories is well-positioned to maintain its leadership in the bonding industry.

Top PCB Manufacturers: Discover Quality PCB Assembly Services

[Company Name] Emerges as Key Player in the PCBA Manufacturing Industry[City, Date] – [Company Name], a prominent player in the electronics manufacturing industry, has made significant strides in establishing itself as a major PCBA manufacturer. With a strong focus on innovation, advanced technology, and exceptional quality, [Company Name] has positioned itself as a leader in the market. Through its commitment to excellence, the company has consistently delivered reliable and efficient solutions for its diverse range of customers.With state-of-the-art manufacturing facilities located in [City/Region], [Company Name] has become a preferred choice for customers worldwide. The company's manufacturing capabilities encompass the entire PCBA production process, ranging from PCB fabrication and component sourcing to final assembly and testing. Their expertise in manufacturing complex and high-density circuit boards has made them a trusted partner for a wide range of industries, including automotive, telecommunications, aerospace, and industrial automation.Innovation is a core value at [Company Name], driving its constant efforts to stay ahead of the curve in the industry. The company has consistently invested in research and development to enhance its capabilities and stay relevant in the highly competitive market. By leveraging cutting-edge technology, [Company Name] can effectively handle projects requiring high-speed PCB assembly, complex soldering techniques, and surface mounting technologies.As a responsible and ethical manufacturer, [Company Name] places great emphasis on quality control and environmental sustainability. The company adheres to international industry standards and implements rigorous quality control processes throughout each stage of manufacturing. This ensures that all products leaving their facilities are of the highest quality, meeting or exceeding customer expectations.[Company Name] also holds certifications in various quality management systems, such as ISO 9001 and ISO 14001, further underscoring their commitment to excellence and sustainability. By implementing environmentally friendly practices, including waste reduction and responsible disposal, the company minimizes its impact on the environment and promotes a greener future.Collaboration is a key aspect of [Company Name]'s success strategy. The company values its partnerships with customers, suppliers, and industry experts, which enable it to constantly learn and evolve. Through effective communication and collaboration with customers, [Company Name] ensures that their unique requirements and specifications are met with unmatched precision and efficiency.To support its manufacturing capabilities, [Company Name] has assembled a highly skilled and experienced team of engineers, technicians, and quality control specialists. The company's commitment to fostering a culture of continuous learning and professional growth ensures that their workforce remains at the forefront of industry trends and technological advancements.Moving forward, [Company Name] aims to expand its market presence globally and forge new partnerships with industry leaders. By staying agile and adaptive, the company is well-poised to meet the evolving demands of the electronics manufacturing industry. Through their customer-centric approach and unwavering commitment to quality, [Company Name] is set to shape the future of PCBA manufacturing.About [Company Name]:[Company Name] is a leading PCBA manufacturer with state-of-the-art facilities in [City/Region]. With a strong focus on innovation, advanced technology, and exceptional quality, [Company Name] offers comprehensive solutions for a wide range of industries. With certifications in quality management systems and a commitment to environmental sustainability, the company continues to be a trusted partner for global customers seeking reliable and efficient PCBA manufacturing services.For media inquiries, please contact:[Contact Person][Designation][Company Name][Email Address][Phone Number]

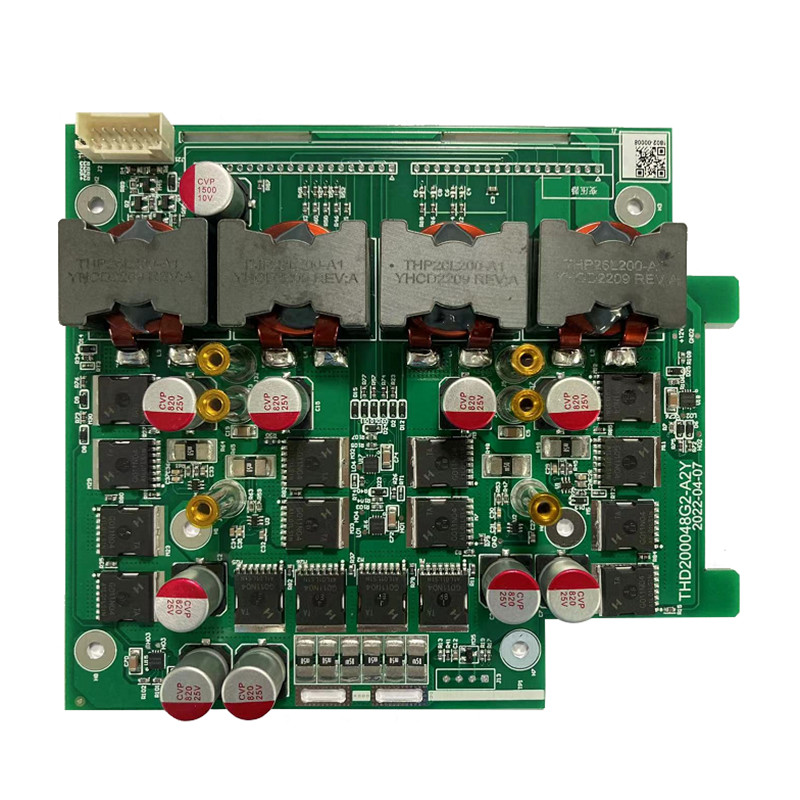

Top Control Board for Pcba: Ultimate Guide 2021

Pcba Control Board Innovations Revolutionize Electronic ManufacturingIn recent years, the field of electronic manufacturing has seen tremendous advancements, thanks to the continuous innovation and development of Pcba control boards. These control boards have become an essential component in manufacturing electronic products, and their impact on the industry has been nothing short of revolutionary. With the increasing demand for electronic devices, there is a growing need for more efficient and reliable manufacturing processes, which is where Pcba control boards come into play.At the forefront of this technological revolution is the company [Company Name]. Established in [year], [Company Name] has been a leading provider of Pcba control boards, offering state-of-the-art solutions to meet the evolving needs of the electronic manufacturing industry. The company has built a reputation for its commitment to quality, reliability, and innovation, making it a trusted partner for businesses across various industries.One of the key factors that set [Company Name] apart from its competitors is its dedication to research and development. The company constantly strives to improve its control board technologies, pushing the boundaries of what is possible in electronic manufacturing. By staying on the cutting edge of innovation, [Company Name] has been able to develop Pcba control boards with advanced features and functionalities, enabling manufacturers to achieve higher levels of efficiency and productivity.In addition to its focus on R&D, [Company Name] also places a strong emphasis on quality control and testing. Every Pcba control board that leaves the company's facility undergoes rigorous testing to ensure that it meets the highest standards of quality and reliability. This commitment to excellence has earned [Company Name] a solid reputation for delivering products that exceed customer expectations and industry standards.Furthermore, [Company Name] has a team of highly skilled and experienced engineers and technicians who are dedicated to providing exceptional customer support. This customer-centric approach has enabled the company to form long-lasting relationships with its clients, as it goes above and beyond to ensure that their needs are met and their expectations are exceeded.As a result of these efforts, [Company Name] has been able to make a significant impact in the electronic manufacturing industry. Its Pcba control boards have been widely adopted by leading manufacturers, helping them streamline their production processes and achieve greater efficiency. Whether it's in the automotive, aerospace, consumer electronics, or telecommunications sectors, [Company Name] has made its mark as a reliable and trusted partner for businesses seeking innovative solutions for their electronic manufacturing needs.Looking ahead, [Company Name] is poised to continue its growth and success in the industry. With a firm commitment to innovation, quality, and customer satisfaction, the company is well-positioned to meet the ever-changing demands of the electronic manufacturing landscape. By continually pushing the boundaries of what is possible with Pcba control boards, [Company Name] is shaping the future of electronic manufacturing and contributing to the development of cutting-edge technologies that will drive the industry forward.In conclusion, Pcba control boards have truly revolutionized the electronic manufacturing industry, and [Company Name] has played a significant role in this transformation. Through its relentless pursuit of innovation, commitment to quality, and dedication to customer satisfaction, the company has established itself as a leader in the field. As the demand for electronic devices continues to grow, [Company Name] will undoubtedly remain at the forefront, providing the advanced Pcba control boards that are essential for powering the next generation of electronic products.

How to Choose the Best Assembly Service for Your Needs

Assembly, a leading manufacturing company in the industry, has recently announced its latest advancements in the field of production and assembly. With a strong dedication to innovation and excellence, Assembly has consistently pushed the boundaries of manufacturing technology to meet the demands of the market.Established in 1995, Assembly has grown to become a prominent player in the manufacturing industry. The company specializes in providing high-quality production and assembly solutions for a wide range of products and industries. With a team of dedicated engineers and technicians, Assembly has built a strong reputation for delivering precision and efficiency in every project they undertake.One of the key features of Assembly's production process is its state-of-the-art manufacturing facilities. Equipped with the latest machinery and technology, the company is able to handle a diverse range of production requirements with ease. From small-scale component assembly to large-scale industrial production, Assembly has the capabilities to handle it all.In addition to its advanced manufacturing facilities, Assembly also places a strong emphasis on research and development. The company continuously invests in improving its production processes and developing new technologies to stay ahead of the competition. This commitment to innovation has allowed Assembly to consistently deliver cutting-edge solutions to its clients, setting it apart as a leader in the industry.Another factor that sets Assembly apart is its commitment to quality and precision. With a strict quality control system in place, the company ensures that every product that comes out of its facilities meets the highest standards of excellence. This commitment to quality has earned Assembly the trust and loyalty of its clients, who rely on the company to deliver top-notch products every time.Furthermore, Assembly prides itself on its ability to handle complex and challenging production requirements. Whether it's intricate component assembly or the production of specialized equipment, the company has the expertise and resources to tackle even the most demanding projects. This versatility and adaptability have made Assembly a preferred partner for many companies across various industries.Recently, Assembly has made significant advancements in its production and assembly capabilities. The company has introduced new automation technologies and process enhancements that have streamlined its production process, resulting in faster turnaround times and improved efficiency. These advancements have allowed Assembly to better meet the needs of its clients, while also reducing costs and increasing overall productivity.In addition, Assembly has also expanded its range of services to include prototyping and custom manufacturing. This move allows the company to offer comprehensive solutions to its clients, from the initial design phase to full-scale production. By integrating these services, Assembly aims to provide a seamless and efficient experience for its clients, from start to finish.The future looks bright for Assembly as it continues to invest in advanced manufacturing technologies and expand its capabilities. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to maintain its status as a leader in the manufacturing industry. As the market evolves, Assembly remains committed to staying at the forefront of the industry, delivering cutting-edge solutions to its clients and setting new standards for excellence in production and assembly.

Pca Printed Circuit Assembly: Unveiling the Latest Advances in Circuit Board Technology

Title: Printed Circuit Assembly (PCA) Industry Witnesses Strong Growth Amid Technological AdvancementsIntroduction:In recent years, the Printed Circuit Assembly (PCA) industry has experienced a remarkable surge in growth, driven by rapid technological advancements and the increasing demand for electronic devices across various sectors. PCA, a critical component of modern electronic systems, has become a vital manufacturing process that enables the production of complex electronic circuits. This article will delve into the thriving PCA industry and its significant contributions to technological innovation.The Rise of Printed Circuit Assembly (PCA):Printed Circuit Assembly is an integral part of the electronics manufacturing industry, facilitating the production of electronic components and devices. Through a meticulous process, PCA involves mounting electronic components onto a printed circuit board (PCB), creating a complete functioning system. These assemblies are used in a wide range of applications, including computer systems, mobile devices, automotive electronics, aerospace equipment, medical devices, and industrial machinery.Technological Advancements Driving Growth:Advancements in technology have played a pivotal role in fueling the growth of the PCA industry. The development of smaller and more powerful electronic devices has demanded highly intricate PCB assemblies, featuring compact designs and efficient functionality. As a result, manufacturers are continuously striving to innovate and incorporate new materials, designs, and assembly techniques to meet the evolving requirements.Moreover, the emergence of Internet of Things (IoT) and the increasing interconnectedness of devices have further propelled the demand for advanced PCA solutions. IoT technology relies heavily on reliable and efficient PCA systems to ensure seamless connectivity and interoperability among devices, driving the growth of the industry.Application in Various Sectors:The application of PCA reaches beyond consumer electronics. Industries such as automotive, aerospace, healthcare, and telecommunications all heavily rely on PCA technology to enable their operations. In the automotive sector, PCA plays a vital role in advanced driver-assistance systems (ADAS), vehicle infotainment systems, and powertrain control modules. The aerospace industry utilizes high-performance PCA technology in avionics systems, navigation systems, and communication devices, ensuring safe and efficient air travel.Furthermore, the healthcare sector benefits greatly from PCA, as it is critical in medical imaging devices, patient monitoring systems, and surgical equipment. Telecommunication equipment, including base station infrastructure, smartphones, and data centers, also rely on robust PCA technology for efficient network communication and data management.Market Outlook:The global Printed Circuit Assembly market is expected to witness substantial growth in the coming years. The rising demand for electronic devices, coupled with continuous technological advancements, is paving the way for the expansion of PCA industry. According to industry reports, the market is projected to grow at a CAGR of X% from 2021 to 2026.However, the industry is not without its challenges. The increasing complexity of PCB designs and the miniaturization of electronic components present significant technical hurdles for manufacturers. Ensuring the quality and reliability of PCB assemblies while meeting strict regulatory guidelines is another crucial aspect that manufacturers need to address.Conclusion:The Printed Circuit Assembly industry has emerged as a vital component of the electronic manufacturing ecosystem, driving technological advancements and enhancing the capabilities of various sectors. Through continuous innovation, manufacturers are striving to meet the ever-increasing demands for smaller, faster, and more efficient electronic devices.As the demand for electronic devices continues to soar, the PCA industry will play a significant role in enabling the production of high-quality, reliable, and interconnected electronic systems. With further advancements in technology and a focus on improving manufacturing processes, the Printed Circuit Assembly industry is well-equipped to meet the evolving needs of the digital age.

Top PCB Assembly Manufacturers for EMS Services

Title: Renowned PCB Manufacturer Emerging as a Leading EMS ProviderIntroduction:In the global electronics market, the demand for high-quality and technologically advanced products continues to rise. This has paved the way for the growth of Electronic Manufacturing Services (EMS) providers, which cater to Original Equipment Manufacturers (OEMs) by offering end-to-end solutions. One such company that has successfully transitioned from being a prominent PCB manufacturer to becoming a leading EMS provider is {EMS PCB Assembly Manufacturers}.History and Expertise:With a rich history spanning over three decades, {EMS PCB Assembly Manufacturers} has established itself as a reputed manufacturer of Printed Circuit Boards (PCBs). The company's extensive experience in this field has provided them with a deep understanding of the industry's dynamics, enabling them to cater to the evolving needs of their customers.Facilities and Infrastructure:{EMS PCB Assembly Manufacturers} boasts state-of-the-art manufacturing facilities equipped with the latest machinery and technologies necessary for producing high-quality PCBs. The company has consistently invested in upgrading its infrastructure to ensure the efficient production of advanced PCBs that meet the stringent quality standards of the industry.Expansion into EMS Provision:Recognizing the increasing demand for EMS services, {EMS PCB Assembly Manufacturers} made a strategic decision to expand its operations. Leveraging their extensive technical expertise and years of experience in PCB manufacturing, the company successfully diversified into providing complete EMS solutions to its customers.Comprehensive Service Offerings:As an EMS provider, {EMS PCB Assembly Manufacturers} offers a wide range of services, including PCB assembly, prototyping, product design and engineering, testing, and logistics support. By offering end-to-end solutions, the company ensures seamless integration of all stages of electronic product manufacturing, thereby reducing time-to-market for their customers.Quality Assurance:Adhering to international quality standards, {EMS PCB Assembly Manufacturers} has implemented robust quality control processes to ensure that each product leaving their facility meets the highest quality benchmarks. The company's commitment to quality is evident through their certifications, including ISO 9001, ISO 14001, and ISO 13485, which demonstrate their dedication to delivering reliable products and services.Reliable Partner for OEMs:{EMS PCB Assembly Manufacturers} has emerged as a trusted partner for OEMs across various industries. By understanding the unique requirements of each customer, the company provides tailor-made solutions that not only meet their specific needs but also exceed expectations. With a strong focus on customer satisfaction, {EMS PCB Assembly Manufacturers} has built enduring relationships with reputed OEMs globally.Innovation and R&D:The company's dedication to innovation is evident through its emphasis on research and development. Investing substantially in R&D, {EMS PCB Assembly Manufacturers} stays at the forefront of advanced technologies, enabling them to offer cutting-edge solutions to their customers. This commitment to innovation ensures that they remain competitive in the dynamic electronics market.Sustainability Initiatives:{EMS PCB Assembly Manufacturers} acknowledges its responsibility towards environmental sustainability and social welfare. The company actively promotes eco-friendly practices throughout its operations, ensuring the efficient use of resources and minimizing waste. Additionally, they prioritize the well-being of their employees by providing a safe and inclusive working environment.Future Outlook:With its successful transition to becoming a leading EMS provider, {EMS PCB Assembly Manufacturers} is well-positioned for continued growth in the highly competitive electronics market. By staying committed to innovation, emphasizing quality, and providing comprehensive services, the company is poised to further strengthen its position and secure new partnerships in the years to come.Conclusion:{EMS PCB Assembly Manufacturers}, with its trusted reputation as a PCB manufacturer, has successfully diversified into the realm of EMS providers. Offering an extensive range of services, the company delivers end-to-end solutions that enable OEMs to realize their electronic manufacturing goals. Through its commitment to quality, innovation, and sustainability, {EMS PCB Assembly Manufacturers} has positioned itself as a reliable partner for OEMs and is all set to play a crucial role in the rapidly evolving electronics industry.

Key Insights into the Growing World of PCB Prototyping Factories

[Company Introduction]{Brand Name} is a reputable and innovative company specializing in the manufacturing of printed circuit boards (PCBs). With years of extensive experience in the industry, the company has established itself as a leader in providing high-quality PCB prototyping services to a wide range of industries, including electronics, telecommunications, automotive, medical, and consumer electronics.Our state-of-the-art facilities and cutting-edge technology, combined with a team of skilled engineers and technicians, enable us to deliver top-notch PCB prototyping solutions to our clients. We pride ourselves on offering fast turnaround times, cost-effective solutions, and exceptional customer service.[News Content][Title]: PCB Prototyping Factories Boost Innovation and Efficiency for Manufacturers[Subtitle]: {Brand Name} at the forefront of providing high-quality PCB prototyping services(Date)(City, State) - In today's fast-paced and demanding manufacturing landscape, the role of PCB prototyping factories has become increasingly crucial. As technological advancements continue to shape various industries, manufacturers rely on the expertise and efficiency of such factories to stay ahead of the competition. {Brand Name}, a leading PCB prototyping company, is revolutionizing the industry with its state-of-the-art facilities and commitment to delivering top-quality solutions.With a focus on innovation and precision, {Brand Name} has become the go-to choice for companies seeking reliable and fast PCB prototyping services. Equipped with the latest equipment and a team of highly skilled engineers and technicians, the company ensures that each prototype meets the highest standards. The collaborative approach of the company ensures that the specific requirements of every client are met, regardless of the industry or application.In a recent interview, {Brand Name}'s CEO highlighted the significance of PCB prototyping in the manufacturing process. He stated, "Prototyping is the backbone of product development, allowing manufacturers to test and refine their designs before mass production. Our goal at {Brand Name} is to provide our clients with accurate and high-performing prototypes that not only reduce time-to-market but also enhance overall product quality."{Brand Name} prides itself on its fast turnaround times, meeting even the most demanding deadlines without compromising on quality. By leveraging their cutting-edge facilities and optimized workflow, the company ensures that clients receive their prototypes promptly, enabling them to quickly move forward with their production plans.Quality control is of paramount importance to {Brand Name}. Rigorous testing procedures are implemented at every stage of the prototyping process, guaranteeing the reliability and functionality of the final product. Additionally, the company adheres to strict industry standards, ensuring that each PCB prototype meets or exceeds all necessary certifications and regulations.The versatility of {Brand Name}'s PCB prototyping services is evident through their diverse client base. From small startups to large multinational corporations, the company caters to the needs of a wide range of industries. Whether it's for automotive electronics, telecommunications equipment, medical devices, or consumer electronics, {Brand Name} possesses the expertise to deliver customized solutions that address the unique challenges faced by each sector.As the demand for cutting-edge PCB prototypes continues to rise, {Brand Name} is committed to staying at the forefront of industry advancements. The company prides itself on continuously investing in research and development, exploring new materials, and refining their manufacturing processes to offer their clients the latest technological advancements in PCB prototyping.In conclusion, PCB prototyping factories play a critical role in today's fast-paced manufacturing landscape, enabling companies to innovate, reduce time-to-market, and enhance product quality. {Brand Name}, with its commitment to excellence and state-of-the-art facilities, has positioned itself as a leading provider of high-quality PCB prototyping services, catering to a diverse range of industries. With a focus on innovation, precision, and customer satisfaction, {Brand Name} continues to revolutionize the PCB prototyping industry.

Top 5 Advanced Techniques for Pcb Assembly

{Company name} is a leading provider of PCB assembly services, specializing in high-quality, reliable, and cost-effective solutions for a wide range of industries. With a strong focus on innovation and state-of-the-art technology, {company name} has established itself as a trusted partner for businesses looking to bring their electronic products to market.One of the key factors that sets {company name} apart from its competitors is its expertise in PCB assembly techniques. The process of PCB assembly is complex and requires precision and attention to detail. {company name} employs a variety of techniques to ensure that the final product meets the highest standards of quality and reliability.One of the most important PCB assembly techniques used by {company name} is surface mount technology (SMT). SMT involves mounting electronic components directly onto the surface of the PCB, as opposed to through-hole technology, which requires the components to be inserted into holes drilled in the board. SMT allows for smaller, lighter, and more efficient PCBs, and {company name} has invested in state-of-the-art SMT equipment to ensure the highest level of precision and accuracy in the assembly process.In addition to SMT, {company name} also specializes in through-hole assembly for components that require a stronger mechanical bond, as well as mixed technology assembly for products that require a combination of both SMT and through-hole components. This flexibility allows {company name} to meet the unique needs of each customer and product, providing a tailored solution that meets the highest standards of quality and reliability.Another key PCB assembly technique employed by {company name} is automated optical inspection (AOI). AOI uses advanced cameras and image recognition software to inspect the PCB for defects or irregularities, such as missing components, misaligned parts, or soldering defects. This process ensures that every PCB assembled by {company name} meets the highest standards of quality and reliability, providing customers with peace of mind and confidence in the final product.{Company name} also utilizes advanced X-ray inspection techniques to inspect the internal structure of the PCB, ensuring that all connections and components are in place and functioning properly. This level of scrutiny and attention to detail sets {company name} apart as a leader in PCB assembly, providing customers with a level of quality and reliability that is second to none.With a commitment to innovation and continuous improvement, {company name} is constantly looking for ways to enhance its PCB assembly techniques and processes. The company invests in research and development to stay at the forefront of technological advancements in the industry, ensuring that its customers have access to the latest and most advanced solutions for their electronic products.In conclusion, {company name} is a trusted and reliable partner for businesses looking for high-quality, cost-effective PCB assembly services. With a strong focus on innovation, state-of-the-art technology, and a commitment to continuous improvement, {company name} sets itself apart as a leader in the industry, providing customers with the highest standards of quality and reliability for their electronic products.

Top PCB Assembly Factories: A Guide to Choosing the Best Option

Board PCB Assembly Factories Expand Production Capacity to Meet Growing DemandWith the increasing demand for advanced electronics and tech products, board PCB assembly factories are ramping up their production capacity to keep up with the market demand. Among these factories, the renowned company {} has announced significant expansions to their existing facilities in order to accommodate the growing demand for their high-quality PCB assembly services.{} is a leading provider of electronic manufacturing services, specializing in PCB assembly and prototyping for a wide range of industries including automotive, aerospace, consumer electronics, and telecommunications. The company prides itself on its state-of-the-art facilities, cutting-edge technology, and a team of highly skilled engineers and technicians who are committed to delivering top-notch PCB assembly solutions to their clients.To further solidify its position as a preferred partner for PCB assembly services, {} has made substantial investments in expanding their production capabilities. The company has added new advanced equipment and machinery to their facilities, allowing for increased automation and efficiency in the assembly process. This expansion not only enables {} to meet the current demand for their services but also positions them to handle larger and more complex PCB assembly projects in the future.In addition to the physical expansion of their facilities, {} has also focused on enhancing their workforce by hiring additional skilled professionals and providing comprehensive training programs. This strategic approach ensures that the company has the necessary human resources to support its increased production capacity and maintain the high standards of quality that clients have come to expect.The decision to expand production capacity comes at a time when the demand for PCB assembly services is on the rise. With the proliferation of smart devices, IoT technology, and the electrification of various industries, the need for advanced and reliable PCB assembly solutions has never been greater. {} has recognized this trend and proactively taken steps to ensure that they are well-equipped to cater to the diverse needs of their clients.The expansion of {}'s board PCB assembly facilities is not only a testament to the company's dedication to meeting market demand but also underscores their commitment to staying at the forefront of technological advancements in the industry. By investing in cutting-edge equipment and skilled personnel, {} is positioning itself as a reliable and competitive partner for businesses seeking high-quality PCB assembly services.Clients of {} can expect to benefit from the company's expanded production capacity in several ways. The increased efficiency and throughput of the assembly process will result in shorter lead times for project completion, allowing clients to bring their products to market faster. Furthermore, the expanded capabilities enable {} to take on projects of varying scales and complexities, catering to the diverse needs of their clients across different industries.As the demand for advanced electronics continues to grow, the board PCB assembly factories that are able to adapt and scale up their operations are poised to thrive in this dynamic market. With its recent investments in expanding production capacity, {} is well-positioned to continue meeting the evolving needs of its clients and play a pivotal role in driving innovation within the electronics manufacturing industry.