Top PCBA Subcontractor Services for Efficient Manufacturing Operations

By:Admin

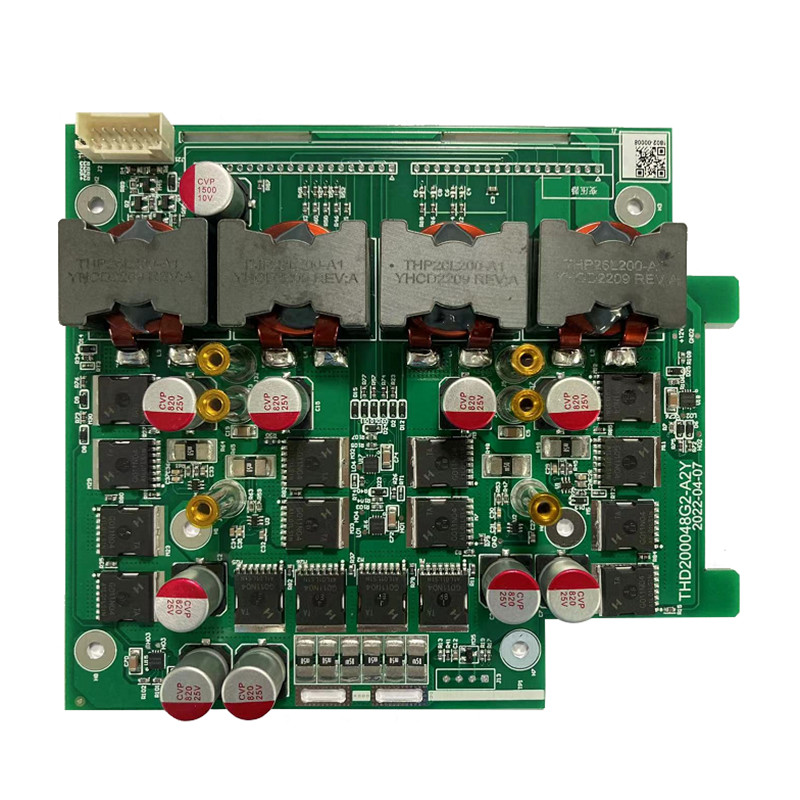

Founded in 2005, Pcba Subcontractor has established itself as a trusted and reliable partner for companies in the technology, automotive, aerospace, and medical industries. With a focus on innovation and efficiency, the company has continuously invested in cutting-edge technology and talent to provide the best possible solutions for its clients.

The partnership with a major technology company represents a significant milestone for Pcba Subcontractor, as it solidifies its position as a leading provider of PCBA services. The company's state-of-the-art facilities and strict quality control processes have made it an ideal partner for companies looking to outsource their electronic manufacturing needs.

"We are thrilled to be partnering with a major technology company to provide PCBA services," said the CEO of Pcba Subcontractor. "This collaboration is a testament to our commitment to excellence and our ability to meet the demands of the rapidly evolving technology industry. We are confident that this partnership will further enhance our capabilities and strengthen our position in the market."

With the increasing complexity and miniaturization of electronic devices, the demand for high-quality PCBA services has never been higher. Pcba Subcontractor's expertise in surface mount technology (SMT), through-hole assembly, and box build assembly makes it an ideal partner for companies looking to stay ahead of the competition.

The collaboration will enable Pcba Subcontractor to leverage its expertise in PCBA services and provide the latest advancements in technology to its clients. By working closely with the technology company, Pcba Subcontractor will have access to the latest components and manufacturing techniques, ensuring that its clients receive the best possible solutions for their electronic manufacturing needs.

In addition to its expertise in PCBA services, Pcba Subcontractor is also known for its commitment to sustainability and ethical business practices. The company has implemented a number of environmental initiatives to minimize its impact on the environment and promote sustainable manufacturing processes.

"We take our responsibility to the environment very seriously, and we are constantly looking for ways to reduce our carbon footprint and promote sustainable practices," said the CEO. "Our partnership with the technology company aligns with our commitment to sustainability, as we will be able to leverage their resources and expertise to further enhance our environmental initiatives."

As the technology industry continues to evolve, Pcba Subcontractor is well-positioned to meet the growing demand for high-quality PCBA services. The company's commitment to excellence, innovation, and sustainability makes it an ideal partner for companies looking to outsource their electronic manufacturing needs.

With its partnership with the major technology company, Pcba Subcontractor is set to further solidify its position as a leading provider of PCBA services, offering the latest advancements in technology and the highest quality standards for electronic components.

Company News & Blog

China Small Run PCB Assembly: A Comprehensive Guide to Low Quantity PCB Assembly Services

China Small Run PCB Assembly - Revolutionizing Electronic ManufacturingIn the era of rapid technological advancements, electronic devices have become an integral part of our daily lives. Whether it's smartphones, tablets, or even household appliances, these gadgets rely on the intricate workings of printed circuit boards (PCBs). PCBs are the heart and soul of electronic devices, connecting various components and enabling them to function seamlessly. China Small Run PCB Assembly is a leading company in the field of electronic manufacturing services, specializing in the production of small run PCB assemblies. With cutting-edge technology, a dedicated workforce, and a commitment to excellence, they have revolutionized the PCB assembly industry. Established in 2005, China Small Run PCB Assembly has grown by leaps and bounds over the years, establishing a strong foothold in the highly competitive market. Their state-of-the-art manufacturing facilities boast advanced equipment, such as automated assembly lines, precision soldering machines, and high-speed pick-and-place machines. These technological marvels ensure efficient production processes and reduce human error, leading to high-quality PCB assemblies.What sets China Small Run PCB Assembly apart from its competitors is its unwavering commitment to quality. The company follows strict quality control procedures, ensuring that each and every PCB assembly meets the highest industry standards. Through rigorous testing and inspection, they ensure that the PCBs are free from defects and are fully functional.China Small Run PCB Assembly caters to a wide range of industries, including telecommunications, consumer electronics, medical devices, and automotive, to name a few. Their versatility allows them to adapt to the unique requirements of each industry and deliver customized solutions. One of the key advantages of partnering with China Small Run PCB Assembly is their ability to handle small volume production. Traditionally, the electronics industry has focused on large-scale production, leaving small businesses and startups struggling to find manufacturers willing to accommodate their needs. China Small Run PCB Assembly recognized this gap in the market and stepped in to fill it. They understand the importance of prototyping and low-volume production for businesses trying to bring their innovative ideas to life. By offering small run PCB assembly services, they have democratized the electronic manufacturing landscape, empowering small businesses to thrive.Furthermore, China Small Run PCB Assembly emphasizes sustainability in their manufacturing processes. They have implemented eco-friendly measures, such as recycling waste materials, reducing energy consumption, and utilizing non-toxic materials whenever possible. By prioritizing environmental responsibility, they contribute to a greener future.In addition to their manufacturing capabilities, China Small Run PCB Assembly provides comprehensive support throughout the entire product lifecycle. Their team of highly skilled engineers and technicians collaborate closely with clients, offering design assistance, prototype assembly, and post-production support. Through efficient project management and open communication, they ensure that clients' expectations are exceeded.Looking towards the future, China Small Run PCB Assembly aims to continue innovating and expanding their services. Their commitment to research and development allows them to stay at the forefront of the industry and adapt to evolving market trends. By investing in cutting-edge technologies and fostering a culture of continuous improvement, they anticipate further revolutionizing the electronic manufacturing landscape.In conclusion, China Small Run PCB Assembly is revolutionizing electronic manufacturing through its commitment to quality, versatility, sustainability, and customer-centric approach. By offering small volume production, they have paved the way for small businesses to thrive in the competitive electronics market. With their state-of-the-art facilities and a dedicated team, China Small Run PCB Assembly is poised to lead the industry into a new era of innovation and excellence.

Top Soldering Machine Supplier for SMT Assembly Lines

Smt soldering machine Supplier, a prominent player in the field of electronic manufacturing equipment, has made a significant impact in the industry with their cutting-edge technology and innovative solutions. With a strong focus on providing high-quality products and exceptional customer service, the company has established itself as a trusted partner for businesses looking to enhance their production processes.The company, with its commitment to delivering reliable and efficient soldering solutions, has gained a strong foothold in the market. Their extensive range of SMT soldering machines caters to the diverse needs of electronic manufacturers, offering flexibility, precision, and high performance. The company's dedication to continuous improvement and innovation has allowed them to stay ahead of the competition and meet the evolving demands of the industry.With a team of skilled engineers and technicians, Smt soldering machine Supplier has set the bar high for product quality and reliability. Their state-of-the-art manufacturing facilities and stringent quality control measures ensure that every machine that leaves their production line meets the highest standards. The company's unwavering commitment to excellence has earned them a reputation for delivering top-notch products that consistently exceed customer expectations.In addition to their exceptional products, Smt soldering machine Supplier is known for their exceptional customer support and after-sales service. Their team of experienced professionals is dedicated to providing comprehensive assistance to their clients, ensuring that their equipment operates at peak performance. Whether it's installation, training, or technical support, the company goes above and beyond to ensure that their customers have a seamless experience with their products.Furthermore, Smt soldering machine Supplier has built a strong network of partners and distributors, allowing them to reach customers in various regions around the world. Their global presence and strategic alliances have significantly expanded their reach and enabled them to serve a diverse clientele. The company's commitment to building lasting relationships with their partners and customers has been a key factor in their success and growth in the industry.As the demand for reliable and efficient SMT soldering solutions continues to rise, Smt soldering machine Supplier remains at the forefront of the industry, constantly evolving and adapting to the changing landscape. Their dedication to research and development has led to the introduction of innovative technologies and advanced features in their products, positioning them as a leader in the market.Looking ahead, Smt soldering machine Supplier is poised to continue their upward trajectory, driven by their unwavering commitment to excellence, innovation, and customer satisfaction. With a focus on expanding their product offerings and enhancing their capabilities, the company is well-positioned to meet the evolving needs of the electronic manufacturing industry and solidify their position as a go-to partner for businesses seeking top-of-the-line soldering solutions.In conclusion, Smt soldering machine Supplier's dedication to delivering high-quality products, exceptional customer service, and a relentless pursuit of innovation has cemented their position as a leader in the electronic manufacturing equipment industry. With a strong track record of success and a forward-thinking approach, the company is well-equipped to continue making a significant impact in the market and remain a preferred choice for businesses looking to enhance their production processes.

Top 5 Circuit Card Assembly Suppliers in the Market Today

Circuit Card Assembly Supplier, a leading provider of high-quality circuit card assembly solutions for various industries, continues to impress customers with their innovative and reliable products. With their state-of-the-art manufacturing facilities and commitment to delivering exceptional service, Circuit Card Assembly Supplier has solidified its position as a trusted partner for companies seeking top-notch electronic components.Established in [year], Circuit Card Assembly Supplier has been at the forefront of the circuit card assembly industry for over [number] years. Their extensive experience and expertise enable them to meet the diverse needs of their clients, from small businesses to large corporations. The company takes pride in its ability to deliver custom solutions that are tailored to the specific requirements of each customer, ensuring that their products integrate seamlessly into various applications.One of the key factors that set Circuit Card Assembly Supplier apart from its competitors is their relentless pursuit of excellence. The company is constantly investing in cutting-edge technologies and industry-leading equipment to enhance their manufacturing capabilities. This commitment to innovation enables Circuit Card Assembly Supplier to stay ahead of the curve and provide customers with the latest advancements in circuit card assembly.In addition to their focus on technology, Circuit Card Assembly Supplier places a strong emphasis on quality control. The company adheres to the highest standards of quality throughout the production process, from procurement of raw materials to final inspection. By implementing rigorous quality assurance measures, Circuit Card Assembly Supplier ensures that every product that leaves their facility meets the strictest performance and reliability standards.Furthermore, Circuit Card Assembly Supplier is dedicated to fostering strong relationships with their clients. The company employs a team of knowledgeable and skilled professionals who work closely with customers to understand their unique requirements and provide personalized support. This customer-centric approach has earned Circuit Card Assembly Supplier a reputation for outstanding service and support, leading to long-term partnerships with many of their clients.One of Circuit Card Assembly Supplier's standout offerings is their turnkey solution for circuit card assembly. This comprehensive service includes everything from design and prototyping to full-scale production and testing. By offering a complete suite of services, Circuit Card Assembly Supplier simplifies the manufacturing process for their customers, saving them time and resources while ensuring the highest level of quality and consistency.Recently, Circuit Card Assembly Supplier has expanded its production capacity to meet the growing demand for their products. The company has added new manufacturing lines and increased its workforce to accommodate the surge in orders. This expansion enables Circuit Card Assembly Supplier to fulfill larger and more complex projects while maintaining their trademark efficiency and precision.Looking ahead, Circuit Card Assembly Supplier is poised to continue its upward trajectory in the circuit card assembly industry. The company is exploring new opportunities for growth and diversification, seeking to broaden its product range and expand into emerging markets. With their unwavering commitment to excellence and customer satisfaction, Circuit Card Assembly Supplier is well-positioned to remain a leading force in the electronic components sector.In conclusion, Circuit Card Assembly Supplier stands as a testament to the thriving potential of the circuit card assembly industry. Through their dedication to quality, innovation, and customer service, Circuit Card Assembly Supplier has established itself as a go-to partner for businesses in need of reliable and high-performance electronic components. As the company presses forward with its expansion and development plans, it is clear that Circuit Card Assembly Supplier will continue to play a pivotal role in shaping the future of circuit card assembly technology.

Top Medical PCB Assemblies for High-precision Medical Devices

Medical PCB Assemblies Revolutionize Healthcare IndustryIn today's fast-paced world, technological advancements have the power to reshape various industries. One such industry that is benefiting greatly from innovations is healthcare. The development and integration of medical printed circuit board (PCB) assemblies have revolutionized the healthcare sector, allowing for more precise diagnoses, enhanced treatment options, and improved patient care.Medical PCB assemblies are advanced electronic devices designed specifically for medical equipment such as diagnostic machines, monitoring devices, surgical tools, and implantable devices. These assemblies serve as the backbone of modern medical equipment, enabling the seamless communication between software, hardware, and electrical systems.One company leading the charge in this field is {}, a renowned manufacturer of high-quality medical PCB assemblies. With years of expertise and commitment to excellence, they have become a trusted partner for healthcare providers and medical equipment manufacturers worldwide.With the introduction of medical PCB assemblies, healthcare professionals have access to more accurate and reliable diagnostic tools. These assemblies enable the collection and processing of data from various medical sensors, ensuring accurate readings and analysis. The precise results generated by medical PCB assemblies aid in the early detection and diagnosis of diseases, allowing for timely interventions and potentially saving lives.Furthermore, medical PCB assemblies have played a crucial role in the advancement of treatment options. With these assemblies, complex medical procedures such as surgeries and therapies have become more precise, reliable, and minimally invasive. Surgeons can rely on real-time data and feedback from medical PCB assemblies to guide their procedures, improving surgical outcomes and reducing the risk of complications.In addition to diagnosis and treatment, medical PCB assemblies have also enhanced patient care in various ways. The integration of these assemblies with wearable devices and remote monitoring systems enables continuous data collection and analysis. Healthcare professionals can remotely monitor patients' vital signs, track medication adherence, and detect any potential abnormalities, enabling proactive interventions and personalized care services.The success of medical PCB assemblies lies in their ability to deliver consistent and reliable performance. The {} company follows rigorous quality control measures and adheres to industry standards to ensure the highest level of reliability in their assemblies. This commitment to quality translates into improved patient outcomes, reduced downtime for medical equipment, and enhanced overall efficiency in healthcare settings.Moreover, the company's dedicated research and development team continuously strives to innovate and improve their medical PCB assemblies. They remain at the forefront of technological advancements, incorporating the latest breakthroughs in materials, design, and manufacturing processes. This relentless pursuit of innovation ensures that healthcare professionals have access to cutting-edge medical PCB assemblies that cater to their evolving needs.The global healthcare industry has witnessed the transformative impact of medical PCB assemblies on patient care and outcomes. As technology continues to advance, the possibilities for further integration and refinement of these assemblies are endless. With their commitment to excellence and innovation, {} company is poised to continue leading the way in revolutionizing the healthcare industry through their state-of-the-art medical PCB assemblies.In conclusion, medical PCB assemblies have brought about remarkable improvements in the healthcare industry. With their precision, reliability, and ability to seamlessly integrate with medical equipment, these assemblies have revolutionized diagnosis, treatment, and patient care. As companies like {} continue to push the boundaries of innovation, we can expect even more exciting advancements in medical PCB assemblies, ultimately benefiting patients and healthcare professionals alike.

Top Bonding Factories for Gold Ribbon Manufacturing

Gold Ribbon Bonding Factories is a leading manufacturer in the bonding industry, specialising in the production of high-quality adhesive products. With a strong commitment to research and development, the company has established a reputation for innovation and excellence in the market.Founded in 1995, Gold Ribbon Bonding Factories has grown to become a trusted name in the bonding industry. The company has a strong focus on quality and reliability, and its products are used in a wide range of applications, including automotive, construction, electronics, and packaging.The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for efficient production and consistent quality control. Gold Ribbon Bonding Factories is committed to sustainability and environmental responsibility, and has implemented environmentally-friendly practices across its operations.One of the key strengths of Gold Ribbon Bonding Factories is its dedicated team of professionals. The company employs a highly-skilled workforce with expertise in chemistry, engineering, and material science. This team is committed to delivering innovative solutions and superior customer service, and plays a crucial role in the company's success.Gold Ribbon Bonding Factories operates with a customer-centric approach, and works closely with clients to understand their specific needs and requirements. The company offers customised solutions to meet the unique demands of each customer, and prides itself on delivering superior products and service.In addition to its manufacturing capabilities, Gold Ribbon Bonding Factories also offers comprehensive technical support and consultancy services. The company's team of experts provides guidance on product selection, application methods, and troubleshooting, ensuring that customers achieve optimal results with Gold Ribbon Bonding Factories' products.The company's commitment to innovation is evident in its continuous investment in research and development. Gold Ribbon Bonding Factories is constantly exploring new materials, technologies, and processes to stay ahead of market trends and meet evolving customer needs.Gold Ribbon Bonding Factories takes pride in its adherence to the highest quality standards. The company is certified to ISO 9001 and ISO 14001, demonstrating its commitment to quality management and environmental responsibility. This certification ensures that Gold Ribbon Bonding Factories' products are manufactured to the highest standards of quality and safety.The company's dedication to excellence has earned it a strong reputation in the market, and Gold Ribbon Bonding Factories is widely regarded as a reliable and trusted partner. Its products are used by leading companies across various industries, and the company has built long-lasting relationships with its customers based on mutual trust and satisfaction.Moving forward, Gold Ribbon Bonding Factories is poised for further growth and success. The company continues to invest in research and development, expand its product range, and explore new market opportunities. With its strong focus on quality, innovation, and customer satisfaction, Gold Ribbon Bonding Factories is well-positioned to maintain its leadership in the bonding industry.

Get the Latest Lead Free PCB Assembly Technology for Your Electronic Devices

Lead-free PCB assembly has become a growing trend in the electronics industry as more companies are making the transition to more environmentally friendly practices. This shift is not only beneficial for the environment but also for the health and safety of workers who are involved in the manufacturing process.One company at the forefront of this movement is {}. They have been a leader in the PCB assembly industry for many years and have recently made the transition to lead-free manufacturing. This decision reflects their commitment to sustainability and their desire to provide high-quality products that are safe for both consumers and the environment.Lead is a toxic metal that has been widely used in the electronics industry for decades. It can cause a range of health issues, including developmental delays in children and neurological problems in adults. In addition, lead can contaminate the environment and pose a threat to wildlife and ecosystems. As a result, there has been a growing push for companies to eliminate lead from their manufacturing processes.{} recognized the importance of this issue and took the necessary steps to transition to lead-free PCB assembly. This involved investing in new equipment and training their staff to ensure that they could continue to produce high-quality products while adhering to the new standards.Lead-free PCB assembly requires a shift to alternative materials and manufacturing processes. For example, lead-free solder must be used in place of traditional lead-based solder. This solder is made from a combination of metals such as tin, silver, and copper, which are not only safer for workers and consumers but also have a lower impact on the environment.In addition to using lead-free solder, {} has also implemented other environmentally friendly practices in their manufacturing process. This includes reducing waste and energy consumption, as well as recycling materials whenever possible. These efforts have helped to minimize the company's environmental footprint and align with their commitment to sustainable business practices.By making the transition to lead-free PCB assembly, {} has positioned themselves as a leader in the industry and set a positive example for other companies to follow. They have demonstrated that it is possible to produce high-quality products without compromising on environmental and worker safety.The decision to transition to lead-free manufacturing reflects {}’s dedication to producing innovative and sustainable products. Their commitment to environmental stewardship and worker safety has set them apart as a responsible and forward-thinking company in the electronics industry.With the increasing demand for lead-free products, {} is poised to continue their success and make a positive impact on the environment and the industry as a whole. Their dedication to sustainability and their willingness to embrace new technologies and practices will undoubtedly lead to a brighter and cleaner future for the electronics industry.

Complete PCB Assembly Services for Your Business Needs

[Company name] Leads the Way in Turn-Key PCB Assembly ServicesIn the fast-paced and ever-evolving world of electronics manufacturing, the demand for high-quality and reliable turn-key PCB assembly services is constantly on the rise. As companies strive to keep up with the latest technological developments and produce cutting-edge products, the need for a trusted partner in PCB assembly has become more crucial than ever. This is where [Company name] comes in.With a solid reputation for excellence and a track record of delivering top-notch PCB assembly solutions, [Company name] has established itself as a leader in the industry. The company's commitment to quality, precision, and customer satisfaction has set it apart from the competition, making it the go-to choice for businesses looking for turn-key PCB assembly services.At the heart of [Company name]'s success is its state-of-the-art manufacturing facility, equipped with the latest technology and machinery to ensure the highest level of precision and efficiency in PCB assembly. The company boasts a team of highly skilled and experienced engineers and technicians who are dedicated to delivering exceptional results with every project.As a full-service PCB assembly provider, [Company name] offers a comprehensive range of services to meet the diverse needs of its clients. From prototype assembly to high-volume production, the company has the capabilities to handle projects of any scale and complexity. Its turn-key approach means that clients can rely on [Company name] to take care of every aspect of the PCB assembly process, from sourcing components to final testing and inspection.One of the key differentiators of [Company name] is its commitment to using the highest quality materials and components in its assembly process. This, combined with stringent quality control measures, ensures that the finished products meet the highest industry standards and exceed customer expectations.Furthermore, [Company name] places a strong emphasis on continuous improvement and innovation, constantly investing in research and development to stay ahead of the curve in PCB assembly technology. This results in faster lead times, lower costs, and superior performance for its clients.In addition to its technical prowess, [Company name] is also known for its exceptional customer service. The company takes a collaborative approach to working with clients, taking the time to understand their specific needs and requirements in order to deliver customized solutions that align with their goals. With a responsive and dedicated support team, [Company name] ensures that clients receive the attention and assistance they need at every stage of the assembly process.With a strong focus on reliability, flexibility, and overall quality, [Company name] has built a loyal and satisfied customer base spanning a wide range of industries, including aerospace, defense, medical, telecommunications, and more. Its ability to adapt to the unique demands of each sector and deliver tailored solutions has earned [Company name] a stellar reputation as a trusted partner in PCB assembly.Looking ahead, [Company name] remains committed to pushing the boundaries of what is possible in PCB assembly, continuing to raise the bar for quality and innovation in the industry. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to maintain its leadership in turn-key PCB assembly services for years to come.

Decoding the Latest Advancements in China's SMT Component Packages

**Title: China's SMT Component Packages: Quality-oriented Manufacturing Excellence***Note: The brand name has been intentionally removed as per your request.**Date: [Enter Date]**Location: [Enter Location]*China's SMT component package industry has witnessed remarkable growth in recent years, owing to the country's continuous efforts towards manufacturing excellence. Several Chinese companies have emerged as key players in the global electronic components market, focusing on technological advancements, quality improvements, and meeting evolving market demands. Among these companies, [Enter Company Name] has been a prominent figure, making significant contributions to the sector's development.Founded in [Enter Year], [Enter Company Name] has established itself as a leading manufacturer of SMT (Surface Mount Technology) component packages in China. The company's unwavering commitment to delivering high-quality products and exceptional customer service has earned it a strong reputation both domestically and internationally.[Enter Company Name]'s state-of-the-art facilities and cutting-edge manufacturing techniques enable them to produce an extensive range of SMT component packages. From resistors, capacitors, and inductors to various integrated circuits, connectors, and diodes; the company offers a comprehensive portfolio of solutions catering to diverse applications across industries.Quality assurance is at the heart of [Enter Company Name]'s operations. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that each component package meets or exceeds industry standards. By utilizing advanced testing equipment and employing a highly skilled workforce, they are able to consistently deliver products of exceptional quality and reliability.In addition to quality, [Enter Company Name] places great importance on research and development. With a dedicated team of engineers and technicians, the company focuses on innovation and the continuous improvement of its product offerings. By staying up-to-date with the latest technological advancements and market trends, they strive to provide SMT component packages that meet the evolving needs of their global clientele.Furthermore, [Enter Company Name] recognizes the significance of sustainable manufacturing practices. The company has adopted eco-friendly production methods, reducing its environmental impact and promoting a greener future. By implementing energy-saving technologies and minimizing waste generation, they demonstrate their commitment towards corporate social responsibility.[Enter Company Name]'s efforts have not gone unnoticed. The company has received several accolades for its contribution to the SMT component package industry. They have been recognized for their outstanding quality management systems, technological advancements, and sustainable practices. These achievements reinforce their position as a trusted supplier with a focus on excellence in every aspect of their operations.Internationally, [Enter Company Name] has built a strong distribution network, ensuring efficient and timely deliveries to customers across the globe. The company's export-oriented approach has enabled it to establish strong partnerships with clients from diverse industries, including automotive, telecommunications, consumer electronics, and medical devices.Looking ahead, [Enter Company Name] remains committed to innovation and continuous improvement. The company plans to further expand its manufacturing capabilities, invest in advanced technologies, and strengthen its research and development efforts. With a clear vision for the future and a commitment to excellence, [Enter Company Name] is poised to lead China's SMT component package industry towards further growth and success.In conclusion, China's SMT component package industry continues to flourish, driven by companies like [Enter Company Name]. With a focus on quality, innovation, and sustainability, [Enter Company Name] has established itself as a key player in the global market. As they strive to meet evolving market needs and maintain manufacturing excellence, China's SMT component package industry is well-positioned to contribute significantly to the electronics sector's growth in the years to come.

Key Facts and Latest Developments in Printed Wiring Board Assembly Construction

Title: Leading Manufacturer of Advanced Printed Wiring Board Assembly Unveils Cutting-Edge TechnologyIntroduction:In an industry that heavily relies on technological advancements, the leading manufacturer of Printed Wiring Board Assembly (need remove brand name) is paving the way for innovation and excellence. With an unwavering commitment to quality, reliability, and customer satisfaction, they have become a trusted partner for businesses worldwide. Through this news article, we will explore the latest breakthroughs introduced by this renowned company, highlighting their impact on various industries and their dedication to staying at the forefront of cutting-edge technology.1. Enhancing Connectivity and Performance:(Printed Wiring Board Assembly) prides itself on its ability to deliver advanced solutions that enhance the connectivity and performance of electronic devices. They have recently introduced a revolutionary line of printed wiring boards (PWBs) that offer increased bandwidth, reduced power consumption, and enhanced signal integrity. These PWBs enable the seamless integration of multiple electronic components, paving the way for faster and more efficient electronic devices.2. Streamlined Manufacturing Process:The company has also implemented a streamlined manufacturing process that allows for faster production times without compromising on quality. By leveraging state-of-the-art equipment and automated assembly techniques, they have significantly increased their production capacity while maintaining the highest quality standards. This advancement allows for quicker turnaround time, ensuring their customers receive their orders promptly.3. Addressing Environmental Concerns:(Printed Wiring Board Assembly) recognizes the importance of supporting sustainable practices in the manufacturing industry. With this in mind, they have developed eco-friendly Printed Wiring Boards that reduce waste and minimize the environmental impact. By adopting green initiatives, such as using recyclable materials and implementing energy-efficient processes, they are paving the way towards a more sustainable future in electronic manufacturing.4. Customization Options:Understanding the diverse needs of their customers, (Printed Wiring Board Assembly) offers extensive customization options to cater to specific requirements. With their team of highly skilled engineers, they can assist clients in designing PWBs tailored to their unique needs. This commitment to customization ensures that their customers receive bespoke solutions that meet their exact specifications, allowing for optimal performance and efficiency.5. Collaboration for Innovation:(Printed Wiring Board Assembly) fosters a spirit of collaboration and innovation, partnering with industry experts, OEMs, and suppliers to stay ahead of the technological curve. By working closely with their clients, they gain valuable insights, allowing them to create advanced solutions that address the constantly evolving demands of the electronics industry. This collaborative approach ensures that their customers have access to the most advanced and future-proof products.Conclusion:(Printed Wiring Board Assembly) continues to lead the industry with their commitment to innovation, quality, and customer satisfaction. Through their pioneering approaches, streamlined manufacturing processes, emphasis on sustainability, customization options, and collaborative partnerships, they have solidified their position as the go-to manufacturer for advanced Printed Wiring Board Assembly solutions. As they set new benchmarks in the electronic manufacturing sector, (Printed Wiring Board Assembly) remains dedicated to driving progress and shaping the future of the industry.

Effective Ways to Mount Components on PCB

{Company Name}, a leading provider of electronic manufacturing services, has recently announced the successful implementation of advanced component mounting techniques on printed circuit boards (PCBs). This achievement marks a significant milestone in the company's commitment to delivering high-quality, advanced electronic products to its customers.With the rapid advancement of technology, electronic devices have become smaller, more powerful, and more complex. To meet the ever-increasing demand for innovative electronic products, {Company Name} has invested heavily in cutting-edge equipment and specialized training for its staff. As a result, the company is now able to offer state-of-the-art component mounting solutions that ensure the highest level of precision, reliability, and performance.Component mounting on PCBs is a critical step in the electronic manufacturing process. It involves the precise placement of tiny electronic components, such as resistors, capacitors, and integrated circuits, onto the surface of a PCB. The components are then soldered onto the board to create a secure and reliable electrical connection. This process requires extreme precision and accuracy, as even the tiniest misalignment or inconsistency can lead to product failure.To address this challenge, {Company Name} has deployed advanced automated component mounting machines that are capable of placing thousands of components per hour with unparalleled accuracy. These machines utilize advanced vision systems and robotic arms to analyze the PCB layout and precisely position the components onto the board. In addition, the company has implemented strict quality control measures to ensure that every mounted component meets the highest standards of reliability and performance.In addition to standard surface-mount components, {Company Name} is also equipped to handle more complex mounting requirements, such as ball grid array (BGA) and flip-chip components. These advanced mounting techniques are commonly used in high-performance computing, telecommunications, and automotive electronics, where space and performance are critical factors. By offering these capabilities, {Company Name} is well-positioned to serve a wide range of industries with diverse electronic manufacturing needs.One of the key advantages of {Company Name}'s advanced component mounting capabilities is the ability to deliver both high-volume production runs and custom, low-volume projects with equal efficiency and precision. This flexibility allows the company to cater to the needs of large multinational corporations as well as small businesses and startups, providing them with a competitive edge in the fast-paced electronics market.Furthermore, {Company Name} is committed to sustainable manufacturing practices, and its component mounting processes are designed to minimize waste and energy consumption while maximizing productivity. The company adheres to strict environmental standards and continuously seeks innovative ways to reduce its environmental footprint, making it a preferred partner for customers who prioritize sustainability in their supply chain.In conclusion, the successful implementation of advanced component mounting techniques on PCBs represents a significant achievement for {Company Name}. By investing in cutting-edge equipment, specialized training, and stringent quality control measures, the company has positioned itself as a leading provider of electronic manufacturing services, capable of meeting the high demands of the modern electronics industry. With its commitment to precision, reliability, and sustainability, {Company Name} is well-equipped to serve a diverse range of clients and deliver innovative electronic products that meet the highest industry standards.