Prototype Smt Assembly Services in China: Everything You Need to Know

By:Admin

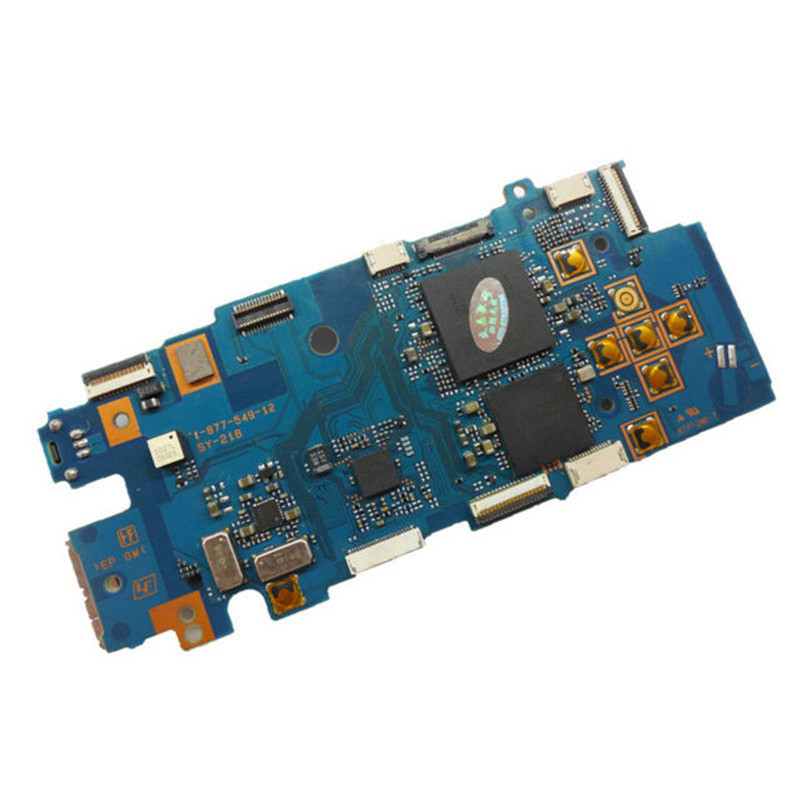

With state-of-the-art equipment and a team of highly skilled technicians, China Prototype SMT Assembly is able to handle even the most complex assembly projects with ease. From prototype assembly to full-scale production, they have the capability to meet the unique needs of their diverse clientele.

One of the key differentiators for China Prototype SMT Assembly is their meticulous attention to detail and strict quality control measures. Every step of the assembly process is closely monitored to ensure that the end result meets the highest standards of excellence. As a result, their clients can have complete confidence in the reliability and performance of the finished products.

In addition to their exceptional technical capabilities, China Prototype SMT Assembly is also known for their outstanding customer service. They understand the importance of clear and open communication throughout the manufacturing process, and they work closely with their clients to ensure that their needs are being met every step of the way.

Furthermore, China Prototype SMT Assembly is dedicated to environmentally-friendly practices and sustainability. They have implemented green initiatives and eco-friendly processes to minimize their impact on the environment while maintaining their commitment to producing top-notch electronic products.

The company's innovative approach to SMT assembly has earned them a solid reputation in the industry, and they continue to attract new clients with their impressive track record of success. Their ability to adapt to the ever-evolving demands of the electronics market has positioned them as a trusted partner for businesses looking to stay ahead of the competition.

Most recently, China Prototype SMT Assembly unveiled an even more advanced assembly process that promises to further streamline production and elevate the quality of their output. This new development is a testament to their ongoing commitment to pushing the boundaries of what is possible in electronics manufacturing.

"We are thrilled to introduce this latest advancement in SMT assembly," said the company's spokesperson. "We believe that this will not only benefit our current clients, but also open up new opportunities for us to expand into even more industries and applications."

With their unwavering dedication to excellence and continuous improvement, China Prototype SMT Assembly is well-positioned to remain a leader in the electronics manufacturing sector for years to come. Their combination of advanced technology, quality control, and customer-centric approach sets them apart as a reliable and innovative partner for businesses seeking top-tier SMT assembly services.

As China Prototype SMT Assembly continues to break new ground in the industry, they are poised to make an even greater impact on the global electronics market. Their commitment to pushing the boundaries of what is possible in SMT assembly is a driving force behind their success, and it is clear that they will continue to raise the bar for the competition in the years to come.

Company News & Blog

Top Quality Single PCB Assembly Factories: A Comprehensive Guide

Single PCB Assembly Factories: Revolutionizing Electronics ManufacturingIn the world of electronics manufacturing, efficiency and precision are crucial to stay competitive in the market. To meet the increasing demand for high-quality electronic products, more and more companies are turning to single PCB assembly factories for their production needs. These state-of-the-art facilities utilize advanced technology and streamlined processes to produce top-of-the-line electronic components.One of the leading companies in this industry is {}. With a strong emphasis on innovation and customer satisfaction, {} has set itself apart as a pioneer in the field of single PCB assembly. The company's commitment to excellence and dedication to continuous improvement have made it a trusted partner for businesses looking to bring their electronic designs to life.At the heart of {}'s success is its cutting-edge factory, equipped with the latest equipment and staffed by highly skilled technicians. The company understands the importance of precision in PCB assembly, and it has invested heavily in advanced machinery to ensure that its products meet the highest standards of quality. From surface mount technology (SMT) to through-hole soldering, {}'s factory is capable of handling a wide range of assembly processes with utmost precision.Moreover, the factory's production line is designed for maximum efficiency, allowing {} to deliver orders in a timely manner without compromising on quality. By streamlining the manufacturing process and removing unnecessary steps, {} has significantly reduced production lead times, enabling its clients to bring their products to market faster. This efficiency has been a game changer for many businesses, especially those operating in fast-paced industries such as consumer electronics and telecommunications.In addition to its advanced machinery and efficient production line, {}'s factory also places a strong emphasis on quality control. Every product that comes off the assembly line undergoes rigorous testing to ensure that it meets the company's stringent quality standards. By maintaining a strict quality control process, {} has earned a reputation for delivering products that are not only reliable but also durable, a key factor in the electronics industry.Aside from its state-of-the-art facilities, {} also offers a range of value-added services to its clients. The company's experienced engineering team provides design consultation and prototyping services, helping businesses to refine their electronic designs before mass production. This collaborative approach has proven to be invaluable for many clients, as it allows them to optimize their designs for manufacturability, which ultimately leads to cost savings and faster time to market.Furthermore, {}'s commitment to sustainability is evident in its factory operations. The company has implemented eco-friendly practices and processes to minimize its environmental impact, such as using energy-efficient machinery and reducing waste through efficient material handling. By prioritizing sustainability, {} not only fulfills its corporate responsibility but also contributes to a greener and more sustainable future for the electronics industry.As the demand for high-quality electronic products continues to rise, single PCB assembly factories like {} are playing a pivotal role in meeting this demand. With their advanced technology, streamlined processes, and commitment to excellence, these facilities are revolutionizing the electronics manufacturing industry. By partnering with a trusted and reliable manufacturer such as {}, businesses can gain a competitive edge in the market and bring their innovative electronic designs to life.

The Importance of Pcb Chip On Board Factories and Their Impact on Electronic Manufacturing

In recent years, the demand for Pcb Chip On Board (COB) technology has been steadily increasing, and there has been a surge in the number of factories producing COB products. One such company that has been at the forefront of this expansion is {}. With state-of-the-art manufacturing facilities and a commitment to innovation, {} has become a leader in producing high-quality COB products for a wide range of applications.{} was established in (year) and has since grown into a leading manufacturer of COB products. The company's dedication to research and development has led to the creation of cutting-edge technologies that have set new industry standards. {}'s COB products are known for their reliability, durability, and performance, making them the top choice for customers around the world.The company's manufacturing facilities are equipped with the latest machinery and technology, allowing for the production of COB products with precision and efficiency. Furthermore, {}'s team of highly skilled engineers and technicians are constantly working to improve their manufacturing processes, ensuring that their products meet the highest quality standards.One of the key factors that set {} apart from its competitors is its commitment to sustainability. The company has implemented environmentally friendly practices throughout its manufacturing processes, aiming to reduce its carbon footprint and minimize waste. This forward-thinking approach has not only benefited the environment but has also positioned {} as a responsible and ethical manufacturer in the industry.Furthermore, {} has a strong focus on customer satisfaction, offering personalized solutions and excellent customer service. The company works closely with its clients to understand their specific needs and requirements, providing tailored COB products that meet and exceed expectations. This customer-centric approach has solidified {}'s reputation as a reliable and trusted partner in the industry.With the increasing demand for COB technology across various sectors, {} has continued to expand its manufacturing capabilities to meet the growing market needs. The company has invested in new facilities and machinery, allowing for increased production capacity and shorter lead times. This strategic expansion has enabled {} to stay ahead of the competition and maintain its position as a leader in the COB industry.In addition to its manufacturing prowess, {} has also focused on strengthening its partnerships and collaborations with other industry players. By working closely with suppliers, distributors, and technology partners, the company has been able to foster innovation and stay ahead of market trends. This collaborative approach has not only benefited {} but has also contributed to the advancement of COB technology as a whole.Looking ahead, {} is poised to continue its growth and success in the COB industry. The company's unwavering commitment to quality, innovation, sustainability, and customer satisfaction has positioned it as a leading manufacturer of COB products. With a strong focus on research and development, advanced manufacturing capabilities, and a customer-centric approach, {} is well-equipped to meet the evolving demands of the market and maintain its status as a top-tier COB manufacturer.

Advanced X-Ray Inspection Technology in China: Latest Updates

China X-Ray Inspection, a leading provider of X-ray imaging systems and solutions, has recently announced a new breakthrough in X-ray inspection technology. The company has successfully developed a next-generation X-ray inspection system that offers unparalleled performance and reliability in detecting foreign objects and ensuring product quality and safety. This innovative system is set to revolutionize the X-ray inspection industry and address the growing demand for advanced inspection solutions.China X-Ray Inspection has been at the forefront of the X-ray inspection industry for years, continuously pushing the boundaries of innovation and technology. With a strong focus on research and development, the company has consistently delivered cutting-edge X-ray inspection systems that cater to a wide range of industries, including food and beverage, pharmaceuticals, and electronics. The company's commitment to excellence and customer satisfaction has earned them a reputation as a trusted partner in the inspection industry.The new X-ray inspection system developed by China X-Ray Inspection is designed to deliver superior performance and accuracy in detecting foreign objects in products. Equipped with state-of-the-art imaging technology and advanced algorithms, the system is capable of identifying even the smallest contaminants, such as metal, glass, stone, bone, and high-density plastics, with unmatched precision. This level of sensitivity ensures that products undergoing inspection meet the highest quality and safety standards, thereby minimizing the risk of product recalls and safeguarding consumer health.In addition to its exceptional detection capabilities, the new X-ray inspection system also offers industry-leading reliability and ease of use. The system is built with robust and durable components, ensuring continuous operation without compromising performance. Moreover, it features an intuitive user interface and advanced software that streamline the inspection process, allowing for efficient and hassle-free operation. These features make the system an ideal choice for manufacturers seeking to enhance their product inspection capabilities while maximizing productivity and minimizing downtime.As a pioneering company in the X-ray inspection industry, China X-Ray Inspection is committed to providing comprehensive and customized solutions to its customers. The new X-ray inspection system is designed to be versatile and adaptable, capable of meeting the specific inspection needs of various products and manufacturing processes. Whether it's inspecting packaged goods, bulk materials, or pharmaceutical products, the system can be tailored to accommodate different product dimensions, packaging types, and inspection requirements, ensuring a seamless integration into existing production lines.Furthermore, China X-Ray Inspection understands the importance of regulatory compliance and product safety in today's global market. The company's new X-ray inspection system is engineered to meet the stringent standards set by regulatory authorities, such as the FDA, HACCP, and GMP. By investing in this advanced system, manufacturers can be confident in their ability to comply with regulations and deliver products that adhere to the highest quality and safety standards, gaining a competitive edge in the marketplace and earning consumer trust.In light of the increasing demand for advanced X-ray inspection solutions, China X-Ray Inspection's new system is set to revolutionize the industry and empower manufacturers to elevate their product quality and safety measures. With its unparalleled performance, reliability, and adaptability, the system is poised to set a new benchmark for X-ray inspection technology, providing manufacturers with a competitive advantage and peace of mind in their production processes.As China X-Ray Inspection continues to lead the way in advancing X-ray inspection technology and delivering innovative solutions, the company remains dedicated to its mission of enabling manufacturers to achieve excellence in product quality and safety. With its new X-ray inspection system, China X-Ray Inspection is poised to further solidify its position as a trusted partner and industry leader in the X-ray inspection market.

How to Build an Efficient EMS Factory: Tips for Success

Effective EMS Factories: Revolutionizing the Electronics Manufacturing IndustryIn today's fast-paced world, the demand for high-quality electronic products is constantly on the rise. From smartphones and tablets to smart home devices and wearable technology, consumers expect nothing but the best when it comes to their electronic devices. This has put a significant amount of pressure on manufacturers to deliver top-notch products in a timely manner.To meet these demands, many companies are turning to Electronic Manufacturing Services (EMS) factories to outsource their production needs. EMS factories specialize in the design, manufacturing, testing, and distribution of electronic components and products, making them an essential part of the modern electronics manufacturing industry.One company that has been at the forefront of revolutionizing the EMS industry is {}. With its state-of-the-art facilities and cutting-edge technology, {} has quickly become a trusted partner for countless companies looking to outsource their manufacturing needs.{} offers a wide range of services to meet the diverse needs of its clients. Whether it's PCB assembly, cable assembly, box build assembly, or full product assembly, {} has the capabilities and expertise to handle it all. With a strong focus on quality and precision, {} ensures that every product that comes out of its factories meets the highest standards in the industry.Furthermore, {} places a strong emphasis on efficiency and cost-effectiveness. By leveraging the latest manufacturing technologies and streamlining its processes, {} is able to deliver products on time and within budget, giving its clients a competitive edge in the market.But what truly sets {} apart from other EMS factories is its commitment to sustainability and social responsibility. With a focus on minimizing its environmental impact and promoting ethical labor practices, {} is dedicated to making a positive contribution to the communities in which it operates.In addition to its manufacturing capabilities, {} also offers a range of value-added services to support its clients every step of the way. From product design and engineering support to supply chain management and logistics, {} is a one-stop solution for all of its clients' manufacturing needs.With a proven track record of success and a strong reputation in the industry, {} has become a go-to partner for companies looking to bring their electronic products to market efficiently and effectively.As the demand for electronic products continues to grow, the role of EMS factories like {} will only become more crucial in the manufacturing landscape. By providing high-quality, cost-effective, and sustainable manufacturing solutions, {} is helping companies around the world stay ahead of the curve in an increasingly competitive industry.In conclusion, {} has established itself as a leader in the EMS industry, setting a new standard for excellence and innovation. With its state-of-the-art facilities, commitment to quality and sustainability, and comprehensive range of services, {} is well-positioned to continue revolutionizing the electronics manufacturing industry for years to come.

Complete PCB Assembly Services for Your Business Needs

[Company name] Leads the Way in Turn-Key PCB Assembly ServicesIn the fast-paced and ever-evolving world of electronics manufacturing, the demand for high-quality and reliable turn-key PCB assembly services is constantly on the rise. As companies strive to keep up with the latest technological developments and produce cutting-edge products, the need for a trusted partner in PCB assembly has become more crucial than ever. This is where [Company name] comes in.With a solid reputation for excellence and a track record of delivering top-notch PCB assembly solutions, [Company name] has established itself as a leader in the industry. The company's commitment to quality, precision, and customer satisfaction has set it apart from the competition, making it the go-to choice for businesses looking for turn-key PCB assembly services.At the heart of [Company name]'s success is its state-of-the-art manufacturing facility, equipped with the latest technology and machinery to ensure the highest level of precision and efficiency in PCB assembly. The company boasts a team of highly skilled and experienced engineers and technicians who are dedicated to delivering exceptional results with every project.As a full-service PCB assembly provider, [Company name] offers a comprehensive range of services to meet the diverse needs of its clients. From prototype assembly to high-volume production, the company has the capabilities to handle projects of any scale and complexity. Its turn-key approach means that clients can rely on [Company name] to take care of every aspect of the PCB assembly process, from sourcing components to final testing and inspection.One of the key differentiators of [Company name] is its commitment to using the highest quality materials and components in its assembly process. This, combined with stringent quality control measures, ensures that the finished products meet the highest industry standards and exceed customer expectations.Furthermore, [Company name] places a strong emphasis on continuous improvement and innovation, constantly investing in research and development to stay ahead of the curve in PCB assembly technology. This results in faster lead times, lower costs, and superior performance for its clients.In addition to its technical prowess, [Company name] is also known for its exceptional customer service. The company takes a collaborative approach to working with clients, taking the time to understand their specific needs and requirements in order to deliver customized solutions that align with their goals. With a responsive and dedicated support team, [Company name] ensures that clients receive the attention and assistance they need at every stage of the assembly process.With a strong focus on reliability, flexibility, and overall quality, [Company name] has built a loyal and satisfied customer base spanning a wide range of industries, including aerospace, defense, medical, telecommunications, and more. Its ability to adapt to the unique demands of each sector and deliver tailored solutions has earned [Company name] a stellar reputation as a trusted partner in PCB assembly.Looking ahead, [Company name] remains committed to pushing the boundaries of what is possible in PCB assembly, continuing to raise the bar for quality and innovation in the industry. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to maintain its leadership in turn-key PCB assembly services for years to come.

Top Gold Wire Bonding Factories: Everything You Need to Know

Gold Wire Bonding Factories have been a crucial part of the electronic manufacturing industry for many years. With the demand for smaller and more advanced electronic devices increasing, the need for reliable and efficient wire bonding factories has become more important than ever. One such company leading the way in this industry is {}.{} is a leading manufacturer of gold wire bonding equipment and has been in business for over 30 years. With a commitment to innovation and quality, {} has established itself as a trusted partner for many electronic device manufacturers around the world. The company's state-of-the-art facilities and advanced technology allow them to produce high-quality gold wire bonding equipment that meets the ever-evolving demands of the industry.The process of gold wire bonding involves using gold wires to connect semiconductor devices to the external leads of the package. This process requires extreme precision and reliability to ensure the longevity and functionality of the electronic devices. {} has a team of highly skilled engineers and technicians who work tirelessly to develop and manufacture wire bonding equipment that meets these strict requirements.In addition to their commitment to quality, {} is also dedicated to sustainability and environmental responsibility. The company uses eco-friendly materials and practices in their manufacturing processes, ensuring that their products are not only reliable but also environmentally friendly. This commitment to sustainability has made {} a preferred choice for many electronic device manufacturers who are looking to minimize their carbon footprint.One of the key factors that set {} apart from other wire bonding factories is their focus on research and development. The company invests heavily in R&D to stay ahead of the curve in terms of technology and innovation. This allows them to consistently improve their products and offer the latest advancements in wire bonding technology to their customers. As a result, {} has earned a reputation for being a leader in the industry and a trusted partner for many electronic device manufacturers.Furthermore, {} takes pride in its customer-centric approach. The company works closely with its clients to understand their specific needs and requirements, ensuring that they receive customized solutions that meet their unique challenges. This collaborative approach has enabled {} to build long-lasting relationships with their clients and establish themselves as a go-to provider of gold wire bonding equipment.With an ever-growing demand for smaller and more advanced electronic devices, the role of gold wire bonding factories has become increasingly important. As electronic devices continue to evolve, so do the requirements for wire bonding equipment. {} recognizes this and is committed to staying at the forefront of the industry by continually developing cutting-edge solutions that meet the needs of their customers.In conclusion, {} is a leading manufacturer of gold wire bonding equipment that has a proven track record of delivering high-quality, reliable, and sustainable solutions to electronic device manufacturers around the world. With a focus on innovation, quality, sustainability, and customer satisfaction, {} has established itself as a trusted partner in the industry. As the demand for smaller and more advanced electronic devices continues to grow, {} remains committed to providing the latest advancements in wire bonding technology to meet the needs of their customers.

Key Insights into the Growing World of PCB Prototyping Factories

[Company Introduction]{Brand Name} is a reputable and innovative company specializing in the manufacturing of printed circuit boards (PCBs). With years of extensive experience in the industry, the company has established itself as a leader in providing high-quality PCB prototyping services to a wide range of industries, including electronics, telecommunications, automotive, medical, and consumer electronics.Our state-of-the-art facilities and cutting-edge technology, combined with a team of skilled engineers and technicians, enable us to deliver top-notch PCB prototyping solutions to our clients. We pride ourselves on offering fast turnaround times, cost-effective solutions, and exceptional customer service.[News Content][Title]: PCB Prototyping Factories Boost Innovation and Efficiency for Manufacturers[Subtitle]: {Brand Name} at the forefront of providing high-quality PCB prototyping services(Date)(City, State) - In today's fast-paced and demanding manufacturing landscape, the role of PCB prototyping factories has become increasingly crucial. As technological advancements continue to shape various industries, manufacturers rely on the expertise and efficiency of such factories to stay ahead of the competition. {Brand Name}, a leading PCB prototyping company, is revolutionizing the industry with its state-of-the-art facilities and commitment to delivering top-quality solutions.With a focus on innovation and precision, {Brand Name} has become the go-to choice for companies seeking reliable and fast PCB prototyping services. Equipped with the latest equipment and a team of highly skilled engineers and technicians, the company ensures that each prototype meets the highest standards. The collaborative approach of the company ensures that the specific requirements of every client are met, regardless of the industry or application.In a recent interview, {Brand Name}'s CEO highlighted the significance of PCB prototyping in the manufacturing process. He stated, "Prototyping is the backbone of product development, allowing manufacturers to test and refine their designs before mass production. Our goal at {Brand Name} is to provide our clients with accurate and high-performing prototypes that not only reduce time-to-market but also enhance overall product quality."{Brand Name} prides itself on its fast turnaround times, meeting even the most demanding deadlines without compromising on quality. By leveraging their cutting-edge facilities and optimized workflow, the company ensures that clients receive their prototypes promptly, enabling them to quickly move forward with their production plans.Quality control is of paramount importance to {Brand Name}. Rigorous testing procedures are implemented at every stage of the prototyping process, guaranteeing the reliability and functionality of the final product. Additionally, the company adheres to strict industry standards, ensuring that each PCB prototype meets or exceeds all necessary certifications and regulations.The versatility of {Brand Name}'s PCB prototyping services is evident through their diverse client base. From small startups to large multinational corporations, the company caters to the needs of a wide range of industries. Whether it's for automotive electronics, telecommunications equipment, medical devices, or consumer electronics, {Brand Name} possesses the expertise to deliver customized solutions that address the unique challenges faced by each sector.As the demand for cutting-edge PCB prototypes continues to rise, {Brand Name} is committed to staying at the forefront of industry advancements. The company prides itself on continuously investing in research and development, exploring new materials, and refining their manufacturing processes to offer their clients the latest technological advancements in PCB prototyping.In conclusion, PCB prototyping factories play a critical role in today's fast-paced manufacturing landscape, enabling companies to innovate, reduce time-to-market, and enhance product quality. {Brand Name}, with its commitment to excellence and state-of-the-art facilities, has positioned itself as a leading provider of high-quality PCB prototyping services, catering to a diverse range of industries. With a focus on innovation, precision, and customer satisfaction, {Brand Name} continues to revolutionize the PCB prototyping industry.

Steps for Efficient PCB Assembly in a Factory

The PCB assembly process is a crucial step in manufacturing electronics, and it requires precision and expertise to ensure the final product meets high-quality standards. [Factory name], a leading electronics manufacturer, is known for its top-notch PCB assembly services that cater to the needs of various industries.With a state-of-the-art facility and a team of skilled technicians, [Factory name] is able to provide efficient and reliable PCB assembly services. The company specializes in both through-hole and surface mount technology (SMT) assembly, offering a wide range of options to suit different customer requirements.The PCB assembly process at [Factory name] involves several key steps that are meticulously carried out to guarantee exceptional results. The first step is the preparation of the PCB, which includes the inspection of the circuit board and the placement of components. This is followed by solder paste application, where a stencil is used to apply solder paste onto the PCB. The next step is the pick and place process, where automated machines accurately place surface mount components onto the PCB.After the components are placed, the PCB undergoes reflow soldering, a critical step that involves the melting of the solder paste to create strong and reliable connections. Once the soldering process is complete, the PCB is inspected to ensure that all components are properly soldered and aligned. Any defects or irregularities are immediately addressed to maintain the highest level of quality.[Factory name] prides itself on its rigorous quality control measures throughout the PCB assembly process. The company utilizes advanced testing equipment and techniques to thoroughly inspect and test the assembled PCBs, guaranteeing that they meet performance and reliability standards. This dedication to quality assurance has earned [Factory name] a reputation for delivering superior PCB assembly services to its customers.In addition to its technical expertise, [Factory name] places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and provide customized solutions that meet their needs. By maintaining open communication and a customer-centric approach, [Factory name] has established long-term partnerships with a wide range of clients across different industries.As a leading electronics manufacturer, [Factory name] is committed to staying at the forefront of technological advancements in the PCB assembly industry. The company continuously invests in research and development to adopt the latest assembly techniques, equipment, and materials, ensuring that it remains a trusted and reliable partner for its customers.The success of [Factory name] in the PCB assembly market can be attributed to its unwavering dedication to quality, precision, and customer satisfaction. The company's ability to consistently deliver exceptional PCB assembly services has positioned it as a preferred choice for a diverse clientele seeking high-quality electronics manufacturing solutions.In conclusion, [Factory name] is a reputable and reliable partner for PCB assembly services, offering a combination of technical expertise, cutting-edge equipment, and a customer-centric approach. With a commitment to quality and innovation, [Factory name] continues to set the standard for excellence in the electronics manufacturing industry. Whether it's a small-scale prototype or a large-scale production run, [Factory name] is well-equipped to handle all PCB assembly needs with the utmost professionalism and efficiency.

Flexible PCB Assembly Services in China: Everything You Need to Know

China Flexible PCB Assembly Company A has recently announced the launch of their new range of flexible printed circuit board (PCB) assembly services, aimed at meeting the growing demand for advanced electronics in various industries. This announcement is in line with the company's commitment to providing high-quality, innovative solutions for their global customer base.Company A is a leading manufacturer and supplier of PCBs for a wide range of applications, including consumer electronics, automotive, medical devices, and industrial equipment. With over 15 years of experience in the industry, the company has gained a reputation for delivering reliable and cost-effective PCB solutions to their clients.The new range of flexible PCB assembly services offered by Company A is set to further enhance their competitive edge in the market. Flexible PCBs are becoming increasingly popular in the electronics industry due to their ability to withstand bending and folding, making them ideal for use in compact and portable devices. With the demand for flexible PCBs on the rise, Company A is well-positioned to capitalize on this trend with their state-of-the-art manufacturing capabilities and expertise in the field.One of the key features of Company A's flexible PCB assembly services is their ability to handle complex designs and tight tolerance requirements. The company is equipped with advanced production facilities and a team of skilled engineers and technicians who are capable of delivering high-quality flexible PCBs that meet the specific needs of their customers. Whether it is a prototype or a large-scale production run, customers can rely on Company A to provide flexible PCB solutions that are tailored to their exact specifications.In addition to their technical expertise, Company A also prides itself on its commitment to quality and customer satisfaction. The company follows strict quality control measures throughout the manufacturing process to ensure that all flexible PCBs meet the highest standards for performance and reliability. Furthermore, their customer support team is dedicated to providing timely and responsive assistance to clients, helping them navigate the complexities of the PCB assembly process and address any concerns or inquiries they may have.As part of their commitment to innovation, Company A continuously invests in research and development to stay ahead of the curve in the rapidly evolving electronics industry. The company is constantly exploring new materials, production techniques, and design methodologies to push the boundaries of what is possible with flexible PCB technology. By staying at the forefront of innovation, Company A remains well-positioned to meet the changing needs of their customers and offer cutting-edge solutions that drive their success.With the launch of their new range of flexible PCB assembly services, Company A is poised to further solidify their position as a leading provider of PCB solutions in the global market. Their dedication to quality, innovation, and customer satisfaction sets them apart from the competition and positions them as a trusted partner for businesses seeking reliable and high-performance flexible PCBs. As the demand for flexible PCBs continues to grow, Company A is well-prepared to meet the needs of their customers and deliver exceptional solutions that drive their success in the electronics industry.

Top Techniques for Surface Mount PCB Assembly

surface mount PCB assembly is rapidly becoming the go-to choice for electronics manufacturers looking for efficient and cost-effective solutions. With their ability to accommodate smaller components and higher component density, surface mount PCBs are revolutionizing the industry.One company at the forefront of this innovation is **(company name)**. With years of experience in the field, **(company name)** has established itself as a leading provider of surface mount PCB assembly services. Their state-of-the-art facilities and cutting-edge technology allow them to meet the rapidly evolving needs of their customers.**(company name)** prides itself on its commitment to quality and customer satisfaction. Their team of skilled technicians and engineers work tirelessly to ensure that each and every PCB assembly meets the highest standards. From prototype development to full-scale production, **(company name)** is dedicated to delivering top-notch solutions to their clients.The company’s expertise lies in their ability to handle complex designs and tight tolerances. Their advanced assembly processes and meticulous attention to detail enable them to produce PCBs with unmatched precision and reliability. Whether it's a simple two-layer board or a multi-layer, high-density design, **(company name)** has the capabilities to deliver the perfect solution.In addition to their technical capabilities, **(company name)** places a strong emphasis on efficiency and turnaround times. They understand the importance of meeting deadlines and strive to provide quick and responsive service to their clients. By utilizing the latest automated equipment and streamlined processes, **(company name)** is able to complete PCB assembly projects in a timely manner without compromising on quality.Furthermore, **(company name)** is committed to sustainability and environmental responsibility. They adhere to strict environmental standards and take proactive measures to minimize waste and energy consumption. By utilizing eco-friendly materials and implementing sustainable practices, **(company name)** is doing their part to reduce their environmental impact.The company also places a strong focus on continuous improvement and innovation. They are constantly investing in research and development to stay ahead of the curve and offer the latest advancements in surface mount PCB assembly. From new materials and component technologies to improved manufacturing techniques, **(company name)** is dedicated to pushing the boundaries of what is possible in the industry.With their unwavering commitment to quality, efficiency, and innovation, it's no wonder that **(company name)** is the preferred choice for many electronics manufacturers. Their proven track record and long-standing relationships with clients are a testament to their reliability and capabilities in the field of surface mount PCB assembly.As the demand for smaller, more powerful electronic devices continues to grow, surface mount PCB assembly will only become more crucial. With **(company name)** at the helm, the industry can rest assured that they have a partner they can trust to deliver outstanding results every time.In conclusion, **(company name)** is leading the way in surface mount PCB assembly with their cutting-edge technology, unwavering commitment to quality, and dedication to customer satisfaction. As the industry continues to evolve, **(company name)** is well-positioned to remain at the forefront and continue to provide innovative solutions to their clients. With their impressive track record and forward-thinking approach, **(company name)** is a name to watch in the world of surface mount PCB assembly.