Quality Medical PCB Assembly Services: Everything You Need to Know

By:Admin

With an extensive background in PCB assembly, Medical PCB Assembly Services has the expertise and capabilities to meet the demands of the medical industry. Their commitment to quality and precision is evident in their advanced manufacturing processes, state-of-the-art equipment, and experienced team of engineers and technicians.

The company's specialized services cater to a wide range of medical devices, including diagnostic equipment, monitoring devices, surgical instruments, and implantable devices. By leveraging their in-depth knowledge of medical regulations and standards, Medical PCB Assembly Services ensures that the devices they assemble are safe, effective, and comply with all relevant requirements.

One of the key advantages of working with Medical PCB Assembly Services is their ability to provide customized solutions that meet the unique needs of each client. Whether it's a prototype for a new medical device or a full-scale manufacturing run, the company can tailor their services to deliver the highest quality PCB assemblies, on time and within budget.

In addition to their technical expertise, Medical PCB Assembly Services also places a strong emphasis on customer satisfaction. They work closely with their clients throughout the entire assembly process, from design and prototyping to testing and production, ensuring that the final product meets their exact specifications and performance requirements.

Furthermore, the company's dedication to quality and reliability extends to their commitment to environmental sustainability and ethical practices. They adhere to strict environmental and ethical guidelines in their manufacturing processes and strive to minimize their environmental impact while delivering superior PCB assembly services.

Medical PCB Assembly Services is known for their reliability, efficiency, and dedication to excellence, making them a trusted partner for medical device manufacturers around the world. Their track record of success and customer satisfaction speaks volumes about the quality of their services and their commitment to advancing medical technology.

It is important to note that Medical PCB Assembly Services is committed to staying at the forefront of technological advancements in the medical industry. They continuously invest in research and development to incorporate the latest innovations and best practices into their PCB assembly processes, ensuring that their clients receive the most advanced and reliable solutions available.

Overall, Medical PCB Assembly Services stands out as a leading provider of PCB assembly services for medical devices, with a strong focus on quality, reliability, and customer satisfaction. Their expertise, capabilities, and commitment to excellence make them a valuable partner for medical device manufacturers seeking high-quality PCB assemblies for their products.

Company News & Blog

Get the Latest Lead Free PCB Assembly Technology for Your Electronic Devices

Lead-free PCB assembly has become a growing trend in the electronics industry as more companies are making the transition to more environmentally friendly practices. This shift is not only beneficial for the environment but also for the health and safety of workers who are involved in the manufacturing process.One company at the forefront of this movement is {}. They have been a leader in the PCB assembly industry for many years and have recently made the transition to lead-free manufacturing. This decision reflects their commitment to sustainability and their desire to provide high-quality products that are safe for both consumers and the environment.Lead is a toxic metal that has been widely used in the electronics industry for decades. It can cause a range of health issues, including developmental delays in children and neurological problems in adults. In addition, lead can contaminate the environment and pose a threat to wildlife and ecosystems. As a result, there has been a growing push for companies to eliminate lead from their manufacturing processes.{} recognized the importance of this issue and took the necessary steps to transition to lead-free PCB assembly. This involved investing in new equipment and training their staff to ensure that they could continue to produce high-quality products while adhering to the new standards.Lead-free PCB assembly requires a shift to alternative materials and manufacturing processes. For example, lead-free solder must be used in place of traditional lead-based solder. This solder is made from a combination of metals such as tin, silver, and copper, which are not only safer for workers and consumers but also have a lower impact on the environment.In addition to using lead-free solder, {} has also implemented other environmentally friendly practices in their manufacturing process. This includes reducing waste and energy consumption, as well as recycling materials whenever possible. These efforts have helped to minimize the company's environmental footprint and align with their commitment to sustainable business practices.By making the transition to lead-free PCB assembly, {} has positioned themselves as a leader in the industry and set a positive example for other companies to follow. They have demonstrated that it is possible to produce high-quality products without compromising on environmental and worker safety.The decision to transition to lead-free manufacturing reflects {}’s dedication to producing innovative and sustainable products. Their commitment to environmental stewardship and worker safety has set them apart as a responsible and forward-thinking company in the electronics industry.With the increasing demand for lead-free products, {} is poised to continue their success and make a positive impact on the environment and the industry as a whole. Their dedication to sustainability and their willingness to embrace new technologies and practices will undoubtedly lead to a brighter and cleaner future for the electronics industry.

Effective Ways to Mount Components on PCB

{Company Name}, a leading provider of electronic manufacturing services, has recently announced the successful implementation of advanced component mounting techniques on printed circuit boards (PCBs). This achievement marks a significant milestone in the company's commitment to delivering high-quality, advanced electronic products to its customers.With the rapid advancement of technology, electronic devices have become smaller, more powerful, and more complex. To meet the ever-increasing demand for innovative electronic products, {Company Name} has invested heavily in cutting-edge equipment and specialized training for its staff. As a result, the company is now able to offer state-of-the-art component mounting solutions that ensure the highest level of precision, reliability, and performance.Component mounting on PCBs is a critical step in the electronic manufacturing process. It involves the precise placement of tiny electronic components, such as resistors, capacitors, and integrated circuits, onto the surface of a PCB. The components are then soldered onto the board to create a secure and reliable electrical connection. This process requires extreme precision and accuracy, as even the tiniest misalignment or inconsistency can lead to product failure.To address this challenge, {Company Name} has deployed advanced automated component mounting machines that are capable of placing thousands of components per hour with unparalleled accuracy. These machines utilize advanced vision systems and robotic arms to analyze the PCB layout and precisely position the components onto the board. In addition, the company has implemented strict quality control measures to ensure that every mounted component meets the highest standards of reliability and performance.In addition to standard surface-mount components, {Company Name} is also equipped to handle more complex mounting requirements, such as ball grid array (BGA) and flip-chip components. These advanced mounting techniques are commonly used in high-performance computing, telecommunications, and automotive electronics, where space and performance are critical factors. By offering these capabilities, {Company Name} is well-positioned to serve a wide range of industries with diverse electronic manufacturing needs.One of the key advantages of {Company Name}'s advanced component mounting capabilities is the ability to deliver both high-volume production runs and custom, low-volume projects with equal efficiency and precision. This flexibility allows the company to cater to the needs of large multinational corporations as well as small businesses and startups, providing them with a competitive edge in the fast-paced electronics market.Furthermore, {Company Name} is committed to sustainable manufacturing practices, and its component mounting processes are designed to minimize waste and energy consumption while maximizing productivity. The company adheres to strict environmental standards and continuously seeks innovative ways to reduce its environmental footprint, making it a preferred partner for customers who prioritize sustainability in their supply chain.In conclusion, the successful implementation of advanced component mounting techniques on PCBs represents a significant achievement for {Company Name}. By investing in cutting-edge equipment, specialized training, and stringent quality control measures, the company has positioned itself as a leading provider of electronic manufacturing services, capable of meeting the high demands of the modern electronics industry. With its commitment to precision, reliability, and sustainability, {Company Name} is well-equipped to serve a diverse range of clients and deliver innovative electronic products that meet the highest industry standards.

Top Pcb Board Assembly Supplier for High-Quality Electronics Production

As a leading PCB Board Assembly Supplier in the industry, our company is dedicated to providing high-quality and reliable electronic manufacturing services to our customers. With a strong focus on innovation and customer satisfaction, we have built a reputation for excellence in the field of PCB assembly.Our state-of-the-art facilities are equipped with the latest technology and machinery, allowing us to meet the diverse and evolving needs of our clients. We have a team of skilled and experienced professionals who are committed to delivering top-notch PCB board assembly services, from prototyping to full-scale production.Our company takes pride in our ability to offer a comprehensive range of services, including PCB design, assembly, testing, and packaging. We work closely with our clients to understand their specific requirements and provide tailored solutions that meet their exact specifications. Whether it's a simple single-layer PCB or a complex multi-layer design, we have the expertise and resources to deliver results that exceed expectations.In addition to our commitment to quality, we place a strong emphasis on efficiency and cost-effectiveness. Our streamlined processes and meticulous attention to detail ensure that we deliver high-quality PCB assemblies on time and within budget. We understand the importance of staying competitive in today's fast-paced market, and we are dedicated to helping our clients achieve their business goals by providing cost-effective solutions that don't compromise on quality.Furthermore, we are committed to upholding the highest standards of quality and safety in all aspects of our operations. Our facilities adhere to strict quality control measures and are certified to industry standards, ensuring that our products meet the highest level of performance and reliability. We also prioritize environmental sustainability and strive to minimize our impact on the environment through responsible manufacturing practices.As a PCB board assembly supplier, we are proud to serve a wide range of industries, including automotive, aerospace, medical, telecommunications, and consumer electronics. Our versatile capabilities and commitment to excellence have allowed us to build longstanding relationships with clients from around the world. We are dedicated to providing exceptional customer service and technical support, and we believe in fostering strong, collaborative partnerships based on trust and mutual success.In conclusion, our company is a trusted and reliable partner for all your PCB board assembly needs. With a focus on quality, efficiency, and customer satisfaction, we are committed to delivering superior results that meet the highest standards in the industry. Whether you're looking for a reliable PCB assembly partner for a one-time project or a long-term collaboration, we have the expertise and resources to meet your needs. Contact us today to learn more about our PCB board assembly services and how we can help bring your electronic manufacturing projects to life.

Quality and Reliable Industrial Instrument Factory

Industrial Instrument Factory is a leading manufacturer of high-quality industrial instruments and equipment. With over 20 years of experience in the industry, they have garnered a reputation for producing reliable and innovative products that meet the needs of their customers.The company specializes in the production of a wide range of industrial instruments, including pressure gauges, thermometers, flow meters, and level sensors. Their products are widely used in various industries, including oil and gas, chemical, pharmaceutical, and food and beverage.One of the key factors that sets Industrial Instrument Factory apart from its competitors is its commitment to quality. The company has implemented stringent quality control measures throughout the production process to ensure that every instrument that leaves their facility meets the highest standards of reliability and accuracy. This dedication to quality has earned them the trust and loyalty of customers around the world.In addition to their focus on quality, Industrial Instrument Factory is also dedicated to innovation. They continuously invest in research and development to improve their existing products and to create new, cutting-edge instruments that address the evolving needs of the industry. Their team of skilled engineers and technicians work tirelessly to stay ahead of the curve and to develop solutions that offer enhanced performance and functionality.Furthermore, Industrial Instrument Factory places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific requirements and to provide tailored solutions that meet their individual needs. The company’s customer-centric approach has led to long-lasting partnerships with a diverse range of businesses, from small enterprises to multinational corporations.As part of their commitment to sustainability, Industrial Instrument Factory has also taken steps to minimize their environmental impact. They have implemented eco-friendly practices in their manufacturing processes and have introduced energy-efficient technologies to reduce their carbon footprint. Additionally, they have established partnerships with suppliers who share their dedication to sustainability, ensuring that their entire supply chain is aligned with their environmental goals.In recent news, Industrial Instrument Factory has announced the launch of a new line of digital instruments that are designed to offer improved accuracy and functionality. The new range includes state-of-the-art digital pressure gauges, thermometers, and flow meters that leverage the latest advancements in technology to deliver precise measurements and real-time data monitoring. These instruments are expected to set a new standard for performance and reliability in the industry.“We are excited to introduce our new line of digital instruments to the market,” said the CEO of Industrial Instrument Factory. “These products represent the culmination of years of research and development, and we are confident that they will meet the needs of our customers and exceed their expectations. We are committed to providing innovative solutions that drive efficiency and productivity for our clients, and we believe that our new digital instruments will achieve just that.”The launch of these new digital instruments underscores Industrial Instrument Factory’s dedication to staying at the forefront of technological advancements in the industry. By introducing cutting-edge products that offer enhanced performance and capabilities, the company aims to solidify its position as a leading provider of industrial instruments and to continue meeting the evolving needs of its customers.Looking ahead, Industrial Instrument Factory is poised to continue its growth and success in the industry. With a focus on quality, innovation, customer satisfaction, and sustainability, the company is well-positioned to remain a trusted partner for businesses seeking reliable and advanced industrial instruments. As they continue to push boundaries and set new standards, Industrial Instrument Factory is set to make a lasting impact on the industry for years to come.

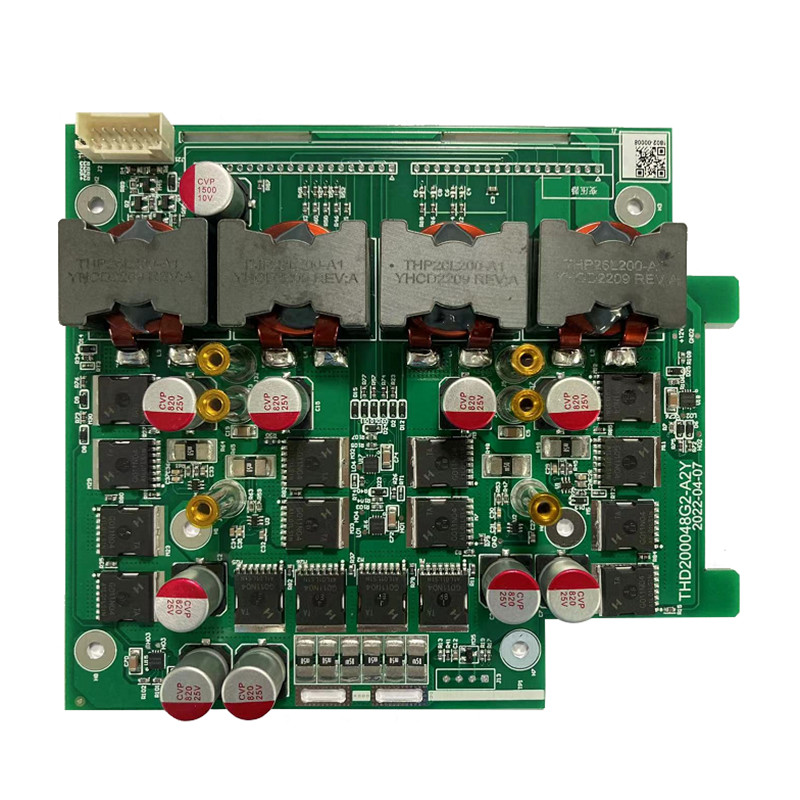

New Power Switch Motherboard Released in China - Find Out More Here

China Power Switch Motherboard, also known as the leading provider of high-performance power supply units, has recently introduced a new line of motherboards, further solidifying its position as a top player in the technology industry. The company, with a strong focus on research and development, has consistently been at the forefront of innovation, and the launch of the new motherboard line is a testament to their dedication to providing cutting-edge solutions to their customers.With an increasing demand for high-quality motherboards, especially in the gaming and professional computing sectors, China Power Switch Motherboard has invested heavily in improving their product offerings. The new line of motherboards boasts an array of advanced features, including top-of-the-line chipset components, enhanced power delivery systems, and support for the latest connectivity standards.In addition to these technical advancements, the company has also emphasized the importance of durability and reliability in their new motherboard line. By leveraging their expertise in power supply technology, they have integrated robust power management capabilities into the motherboard design, ensuring stable and efficient performance even under heavy workloads.Furthermore, the introduction of the new motherboard line aligns with China Power Switch Motherboard's commitment to sustainability and environmental responsibility. The company has implemented stringent eco-friendly manufacturing processes and utilized recyclable materials in the production of their motherboards, minimizing their environmental impact without compromising on quality.In a recent statement, a spokesperson for China Power Switch Motherboard highlighted the company's dedication to meeting the evolving needs of the technological landscape. "As the demand for high-performance computing continues to grow, we recognize the importance of providing reliable and feature-rich motherboards that cater to the diverse requirements of our customers," the spokesperson stated. "Our new line of motherboards exemplifies our relentless pursuit of innovation and quality, and we are excited to bring these cutting-edge solutions to the market."The introduction of the new motherboard line has already generated significant interest within the technology community. Industry experts have commended China Power Switch Motherboard for their commitment to pushing the boundaries of motherboard technology and delivering products that exceed customer expectations.In addition to advancing technological capabilities, China Power Switch Motherboard has established a strong reputation for providing exceptional customer support and aftersales services. Customers can expect prompt assistance and reliable guidance from the company's knowledgeable technical support team, ensuring a seamless experience from product selection to post-purchase assistance.Looking ahead, China Power Switch Motherboard has outlined plans for continued innovation and expansion across their product portfolio. With a focus on incorporating the latest technological advancements and addressing the evolving needs of the market, the company is poised to maintain its position as a key player in the global technology industry.As the demand for high-performance motherboards continues to rise, China Power Switch Motherboard remains dedicated to delivering top-tier solutions that empower users to unleash the full potential of their computing systems. With a strong emphasis on quality, reliability, and sustainability, the company is well-positioned to shape the future of motherboard technology and set new standards for excellence in the industry.

High-Quality Circuit Board Assembly Services for Electronics

Circuit Board Assembly Company Leads the Way in Cutting-Edge TechnologyIn today's fast-paced and technology-driven world, the demand for high-quality circuit board assemblies is on the rise. Companies are constantly seeking new and innovative ways to improve their products and stay ahead of the competition. One company that has been at the forefront of this industry is {}, a leading provider of cutting-edge circuit board assembly solutions.Founded in 1998, {} has quickly established itself as a trusted name in the industry, known for its commitment to quality, innovation, and customer satisfaction. The company has built a strong reputation for providing top-of-the-line circuit board assembly services to a wide range of clients, including those in the aerospace, defense, medical, and telecommunications industries.With state-of-the-art facilities and a team of highly skilled and experienced professionals, {} has the capability to handle complex and challenging projects with ease. The company's commitment to using the latest technology and advanced manufacturing processes has allowed it to stay ahead of the curve and continue to meet the ever-evolving needs of its clients.{} offers a comprehensive range of services, including PCB design, prototype assembly, surface mount assembly, through-hole assembly, and full system integration. The company's dedication to quality is evident in its rigorous quality control processes, ensuring that every product that leaves its facility meets the highest standards of excellence.One of the key differentiators for {} is its ability to provide customized solutions that are tailored to meet the specific requirements of each client. The company works closely with its clients to understand their unique needs and develop custom circuit board assembly solutions that are designed to deliver optimal performance and reliability.In addition to its commitment to quality and innovation, {} is also dedicated to sustainable and environmentally friendly practices. The company takes pride in its efforts to minimize waste and reduce its environmental impact, ensuring that its operations are as eco-friendly as possible.One of the most recent achievements for {} has been its successful integration of advanced artificial intelligence and machine learning capabilities into its manufacturing processes. By leveraging the power of AI and machine learning, {} has been able to enhance its production efficiency, improve product quality, and reduce time-to-market for its clients.The integration of AI and machine learning has enabled {} to analyze large volumes of data and identify patterns and trends that were previously undetectable. This has allowed the company to make data-driven decisions that have led to significant improvements in its manufacturing processes and overall business operations.With its continued focus on innovation and technology, {} is well-positioned to lead the way in the circuit board assembly industry. The company's relentless pursuit of excellence and its dedication to staying ahead of the curve have made it a preferred partner for clients seeking cutting-edge solutions to their circuit board assembly needs.As the demand for high-quality circuit board assemblies continues to grow, {} remains committed to pushing the boundaries of what is possible, setting new standards for excellence, and delivering unparalleled value to its clients. With its unwavering dedication to innovation and customer satisfaction, {} is poised to remain a driving force in the industry for years to come.

Leading Chip On Board Manufacturer: Everything You Need to Know

Global Chip On Board Manufacturer Expands Reach with Introduction of Advanced TechnologyThe chip on board (COB) technology industry has witnessed rapid growth in recent years, with the demand for integrated circuits and semiconductor devices continuing to rise. As one of the leading manufacturers in this space, the introduction of advanced technology by {Company Name} is set to further expand the company's reach and solidify its position as a key player in the industry.{Company Name} has been at the forefront of COB technology innovation, leveraging its expertise to develop cutting-edge solutions that cater to the evolving needs of various sectors, including consumer electronics, automotive, healthcare, and industrial applications. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible with COB technology, and its latest introduction of advanced technology is a testament to its commitment to driving industry advancements.The advanced technology introduced by {Company Name} is designed to address the growing demand for high-performance COB solutions that deliver superior functionality and reliability. Leveraging state-of-the-art manufacturing processes and advanced materials, the new technology offers enhanced performance capabilities, increased efficiency, and greater flexibility, making it suitable for a wide range of applications.One of the key benefits of the new technology is its ability to deliver superior thermal management, which is crucial for ensuring the longevity and reliability of COB devices. By effectively dissipating heat and minimizing thermal resistance, the technology enables COB devices to operate at optimal levels, even in demanding operating conditions. This makes it particularly well-suited for applications in industries such as automotive and industrial, where thermal management is a critical factor.Moreover, the advanced technology introduced by {Company Name} also offers enhanced integration capabilities, allowing for greater miniaturization and increased functionality in compact form factors. This opens up new possibilities for designers and engineers to develop innovative solutions that require high levels of integration and performance, while also meeting the demand for smaller and more energy-efficient devices.In addition to its technical capabilities, the new technology also underscores {Company Name}'s commitment to sustainability and environmental responsibility. By optimizing power efficiency and minimizing waste, the technology aligns with the company's efforts to develop eco-friendly solutions that reduce the environmental impact of electronic devices.The introduction of advanced technology by {Company Name} is expected to have a significant impact on the COB market, offering customers access to a new generation of high-performance and sustainable solutions. With its proven track record of delivering cutting-edge COB technology, the company is poised to capitalize on the growing demand for advanced semiconductor devices and expand its market presence across various industry verticals.Commenting on the introduction of the advanced technology, {Company Name}'s CEO expressed confidence in the company's ability to set new industry benchmarks and deliver value to its customers. He highlighted the importance of continuous innovation and collaborative partnerships in driving technological advancements, and emphasized {Company Name}'s commitment to staying ahead of market trends and customer expectations.As the demand for COB technology continues to grow, {Company Name}'s introduction of advanced technology is set to disrupt the industry and pave the way for new possibilities in the semiconductor market. With its focus on performance, reliability, and sustainability, the company is well-positioned to lead the charge towards a new era of COB technology that meets the evolving needs of the market and delivers lasting value to its customers.

Quality Medical PCB Assembly Services That Ensure Seamless Precision

**Title: Revolutionary Medical PCB Assembly Services Pave the Way for Enhanced Healthcare Solutions***Introduction*In today's rapidly evolving world of medical technology, companies like {Brand Name} are emerging as leaders, driven by their innovative Medical PCB Assembly Services. This groundbreaking technology is revolutionizing the healthcare industry and propelling advancements in medical equipment, ensuring efficient and precise diagnostics, treatment, and care for patients worldwide. With a deep understanding of the industry's needs, {Brand Name} is at the forefront of delivering cutting-edge medical PCB assembly services, providing a robust foundation for the development of life-saving technologies.**Innovative Medical PCB Assembly Services**{Brand Name}'s Medical PCB Assembly Services offer unparalleled precision, reliability, and scalability, enabling medical equipment manufacturers to push boundaries and bring breakthrough technologies to life. These services encompass a wide range of capabilities, from prototype assembly to full-scale production. The company employs state-of-the-art manufacturing techniques, utilizing advanced machinery, and highly skilled professionals to deliver unrivaled quality.The medical PCB assemblies provided by {Brand Name} undergo stringent testing procedures to ensure accuracy, durability, and adherence to the industry's strictest regulations. With an emphasis on precision engineering, these assemblies guarantee optimal performance of medical devices, facilitating precise diagnostics, efficient treatment, and enhanced patient care.**Meeting Industry-Specific Requirements**The medical field demands the highest standards of quality, reliability, and safety. Recognizing this, {Brand Name}'s expertise lies in crafting medical PCB assemblies that meet and exceed these rigorous requirements. The company's manufacturing facility adheres strictly to international standards such as ISO 13485 for medical devices. These standards ensure that the final product is safe, reliable, and consistent, meeting the needs of healthcare providers worldwide.{Brand Name}'s comprehensive knowledge of the medical industry allows them to optimize PCB assembly services specifically to meet the unique demands of the healthcare sector. Whether it is for diagnostic imaging equipment, patient monitoring devices, therapeutic systems, or cutting-edge surgical instruments, the company offers tailored solutions that enhance functionality, accuracy, and user experience.**Collaborative Approach and Advanced Technology Integration**{Brand Name} takes a collaborative approach when working with their clients in the medical field. By engaging in open communication and understanding the unique requirements of each project, the company aims to develop customized PCB assembly solutions aligned with their clients' goals and objectives.Furthermore, {Brand Name} integrates the latest technological advancements in their medical PCB assemblies, ensuring compatibility with emerging innovations. The company's engineering team stays up-to-date with the ever-changing landscape of medical technology, meticulously selecting components and employing advanced manufacturing techniques. This adaptability allows for seamless integration of new medical technologies, resulting in groundbreaking devices that set new benchmarks in healthcare.**Driving Advancements in Healthcare Technology**The impact of {Brand Name}'s Medical PCB Assembly Services on the healthcare industry remains unparalleled. By partnering with medical equipment manufacturers, the company facilitates the creation of cutting-edge devices that improve patient outcomes, enhance diagnostic accuracy, and revolutionize treatment methodologies.Moreover, these medical PCB assemblies enable the miniaturization of devices, making them more portable and accessible. This portability broadens the scope of healthcare services, allowing medical professionals to deliver top-quality care in remote areas and emergency situations.In conclusion, {Brand Name}'s visionary approach to Medical PCB Assembly Services revolutionizes the healthcare industry. By offering precise, reliable, and scalable solutions, they enable medical equipment manufacturers to push boundaries, improve patient care, and bring life-saving technologies to the forefront. With a commitment to quality, reliability, and safety, {Brand Name} is driving advancements in healthcare technology and shaping the future of medical care worldwide.

Complete PCB Assembly Services for Your Business Needs

[Company name] Leads the Way in Turn-Key PCB Assembly ServicesIn the fast-paced and ever-evolving world of electronics manufacturing, the demand for high-quality and reliable turn-key PCB assembly services is constantly on the rise. As companies strive to keep up with the latest technological developments and produce cutting-edge products, the need for a trusted partner in PCB assembly has become more crucial than ever. This is where [Company name] comes in.With a solid reputation for excellence and a track record of delivering top-notch PCB assembly solutions, [Company name] has established itself as a leader in the industry. The company's commitment to quality, precision, and customer satisfaction has set it apart from the competition, making it the go-to choice for businesses looking for turn-key PCB assembly services.At the heart of [Company name]'s success is its state-of-the-art manufacturing facility, equipped with the latest technology and machinery to ensure the highest level of precision and efficiency in PCB assembly. The company boasts a team of highly skilled and experienced engineers and technicians who are dedicated to delivering exceptional results with every project.As a full-service PCB assembly provider, [Company name] offers a comprehensive range of services to meet the diverse needs of its clients. From prototype assembly to high-volume production, the company has the capabilities to handle projects of any scale and complexity. Its turn-key approach means that clients can rely on [Company name] to take care of every aspect of the PCB assembly process, from sourcing components to final testing and inspection.One of the key differentiators of [Company name] is its commitment to using the highest quality materials and components in its assembly process. This, combined with stringent quality control measures, ensures that the finished products meet the highest industry standards and exceed customer expectations.Furthermore, [Company name] places a strong emphasis on continuous improvement and innovation, constantly investing in research and development to stay ahead of the curve in PCB assembly technology. This results in faster lead times, lower costs, and superior performance for its clients.In addition to its technical prowess, [Company name] is also known for its exceptional customer service. The company takes a collaborative approach to working with clients, taking the time to understand their specific needs and requirements in order to deliver customized solutions that align with their goals. With a responsive and dedicated support team, [Company name] ensures that clients receive the attention and assistance they need at every stage of the assembly process.With a strong focus on reliability, flexibility, and overall quality, [Company name] has built a loyal and satisfied customer base spanning a wide range of industries, including aerospace, defense, medical, telecommunications, and more. Its ability to adapt to the unique demands of each sector and deliver tailored solutions has earned [Company name] a stellar reputation as a trusted partner in PCB assembly.Looking ahead, [Company name] remains committed to pushing the boundaries of what is possible in PCB assembly, continuing to raise the bar for quality and innovation in the industry. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to maintain its leadership in turn-key PCB assembly services for years to come.

Top PCB Assembly Manufacturers for EMS Services

Title: Renowned PCB Manufacturer Emerging as a Leading EMS ProviderIntroduction:In the global electronics market, the demand for high-quality and technologically advanced products continues to rise. This has paved the way for the growth of Electronic Manufacturing Services (EMS) providers, which cater to Original Equipment Manufacturers (OEMs) by offering end-to-end solutions. One such company that has successfully transitioned from being a prominent PCB manufacturer to becoming a leading EMS provider is {EMS PCB Assembly Manufacturers}.History and Expertise:With a rich history spanning over three decades, {EMS PCB Assembly Manufacturers} has established itself as a reputed manufacturer of Printed Circuit Boards (PCBs). The company's extensive experience in this field has provided them with a deep understanding of the industry's dynamics, enabling them to cater to the evolving needs of their customers.Facilities and Infrastructure:{EMS PCB Assembly Manufacturers} boasts state-of-the-art manufacturing facilities equipped with the latest machinery and technologies necessary for producing high-quality PCBs. The company has consistently invested in upgrading its infrastructure to ensure the efficient production of advanced PCBs that meet the stringent quality standards of the industry.Expansion into EMS Provision:Recognizing the increasing demand for EMS services, {EMS PCB Assembly Manufacturers} made a strategic decision to expand its operations. Leveraging their extensive technical expertise and years of experience in PCB manufacturing, the company successfully diversified into providing complete EMS solutions to its customers.Comprehensive Service Offerings:As an EMS provider, {EMS PCB Assembly Manufacturers} offers a wide range of services, including PCB assembly, prototyping, product design and engineering, testing, and logistics support. By offering end-to-end solutions, the company ensures seamless integration of all stages of electronic product manufacturing, thereby reducing time-to-market for their customers.Quality Assurance:Adhering to international quality standards, {EMS PCB Assembly Manufacturers} has implemented robust quality control processes to ensure that each product leaving their facility meets the highest quality benchmarks. The company's commitment to quality is evident through their certifications, including ISO 9001, ISO 14001, and ISO 13485, which demonstrate their dedication to delivering reliable products and services.Reliable Partner for OEMs:{EMS PCB Assembly Manufacturers} has emerged as a trusted partner for OEMs across various industries. By understanding the unique requirements of each customer, the company provides tailor-made solutions that not only meet their specific needs but also exceed expectations. With a strong focus on customer satisfaction, {EMS PCB Assembly Manufacturers} has built enduring relationships with reputed OEMs globally.Innovation and R&D:The company's dedication to innovation is evident through its emphasis on research and development. Investing substantially in R&D, {EMS PCB Assembly Manufacturers} stays at the forefront of advanced technologies, enabling them to offer cutting-edge solutions to their customers. This commitment to innovation ensures that they remain competitive in the dynamic electronics market.Sustainability Initiatives:{EMS PCB Assembly Manufacturers} acknowledges its responsibility towards environmental sustainability and social welfare. The company actively promotes eco-friendly practices throughout its operations, ensuring the efficient use of resources and minimizing waste. Additionally, they prioritize the well-being of their employees by providing a safe and inclusive working environment.Future Outlook:With its successful transition to becoming a leading EMS provider, {EMS PCB Assembly Manufacturers} is well-positioned for continued growth in the highly competitive electronics market. By staying committed to innovation, emphasizing quality, and providing comprehensive services, the company is poised to further strengthen its position and secure new partnerships in the years to come.Conclusion:{EMS PCB Assembly Manufacturers}, with its trusted reputation as a PCB manufacturer, has successfully diversified into the realm of EMS providers. Offering an extensive range of services, the company delivers end-to-end solutions that enable OEMs to realize their electronic manufacturing goals. Through its commitment to quality, innovation, and sustainability, {EMS PCB Assembly Manufacturers} has positioned itself as a reliable partner for OEMs and is all set to play a crucial role in the rapidly evolving electronics industry.