State-of-the-Art Surface Mount Assembly Factory Opens for Production

By:Admin

[City, State, Date] – [Company Name], a leading provider of electronic manufacturing services, has recently announced the launch of its new surface mount assembly factory. The state-of-the-art facility is equipped with the latest technology and machinery to meet the growing demand for electronic components and devices in the market.

The new factory is part of [Company Name]'s commitment to providing high-quality, cost-effective manufacturing solutions to its customers. With the increasing complexity and miniaturization of electronic devices, the demand for surface mount assembly services has been on the rise. The new facility is designed to meet this demand and to provide customers with efficient, reliable, and scalable manufacturing capabilities.

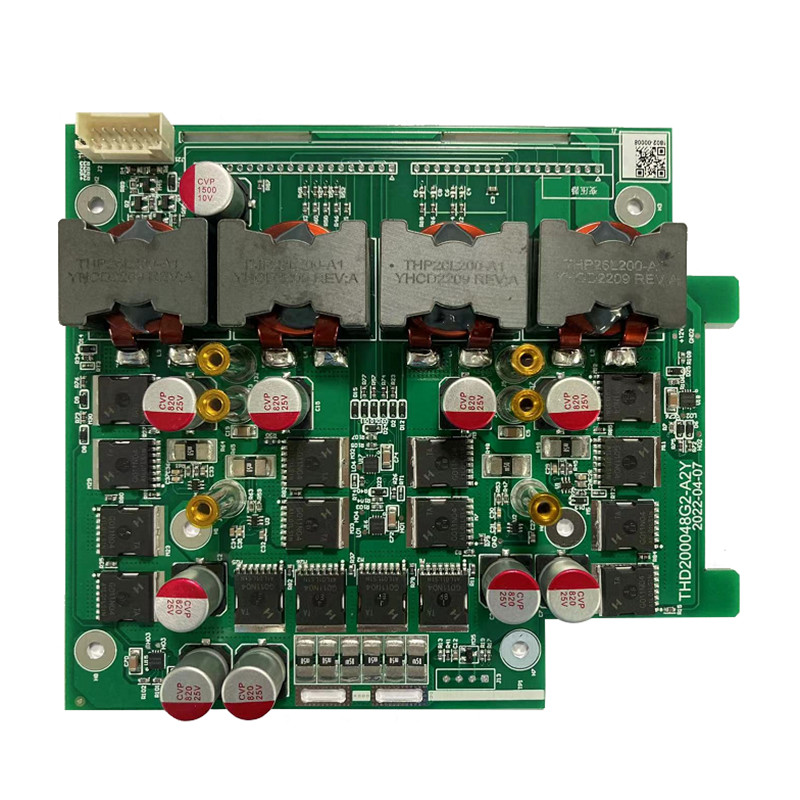

The surface mount assembly factory is equipped with advanced pick-and-place machines, automated soldering equipment, and precision quality control systems. This allows [Company Name] to handle a wide range of electronic components, including microchips, capacitors, resistors, and other surface-mount devices. The factory is also set up to accommodate quick changeovers and rapid prototyping, enabling [Company Name] to offer fast turnaround times and flexible manufacturing options to its customers.

In addition to its cutting-edge equipment, the new facility also boasts a highly skilled and experienced team of engineers and technicians. The team is trained to work with the latest industry standards and best practices, ensuring that all products manufactured at the factory meet the highest quality and reliability standards. This expertise, combined with the advanced machinery, positions [Company Name] as a leading provider of surface mount assembly services in the industry.

"We are excited to announce the launch of our new surface mount assembly factory," said [Spokesperson Name], CEO of [Company Name]. "This investment is a testament to our commitment to providing our customers with the best possible manufacturing solutions. With the growing demand for electronic components and devices, we are confident that our new facility will enable us to meet the needs of our customers and the market."

The launch of the surface mount assembly factory is part of [Company Name]'s broader expansion strategy to strengthen its position in the electronic manufacturing services industry. The company has been experiencing strong growth in recent years, driven by the increasing demand for electronic products in various sectors, including automotive, telecommunications, consumer electronics, and more. The new facility will allow [Company Name] to further expand its capabilities and to take on larger and more complex projects for its customers.

In addition to its new surface mount assembly factory, [Company Name] also offers a wide range of other manufacturing services, including through-hole assembly, PCB assembly, cable and harness assembly, testing and inspection, and more. The company is committed to providing end-to-end manufacturing solutions, from design and prototyping to full-scale production and aftermarket support.

As the demand for electronic devices continues to grow, the launch of [Company Name]'s new surface mount assembly factory comes at a pivotal time. With its advanced technology, experienced team, and commitment to quality, [Company Name] is well-positioned to meet the evolving needs of the market and to drive innovations in electronic manufacturing.

For more information about [Company Name] and its surface mount assembly services, please visit [company website].

Company News & Blog

High-quality Soldering Process Factory Offers Efficient Manufacturing Solutions

Smt Soldering Process Factory Leads the Way in Advanced Manufacturing TechnologySmt Soldering Process Factory, a trailblazer in the field of advanced manufacturing technology, has been making waves in the industry with its cutting-edge soldering process solutions. The company, with its headquarters in (location), has earned a reputation for its innovative approach to soldering processes and has become a go-to destination for businesses looking to enhance their manufacturing capabilities.With a strong focus on research and development, Smt Soldering Process Factory has been at the forefront of driving technological advancements in the soldering industry. The company’s commitment to innovation and excellence has set it apart from its competitors, making it a leading player in the global manufacturing landscape.The success of Smt Soldering Process Factory can be attributed to its state-of-the-art facilities, experienced team, and a customer-centric approach. The company’s manufacturing plant is equipped with the latest machinery and equipment, allowing it to deliver superior quality soldering solutions to its clients. Additionally, the team at Smt Soldering Process Factory comprises of highly skilled engineers and technicians who are dedicated to pushing the boundaries of technological innovation.In addition to its impressive infrastructure and talented workforce, Smt Soldering Process Factory also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and provide them with customized soldering solutions that align with their business goals. This personalized approach has enabled Smt Soldering Process Factory to build long-lasting relationships with its clients, earning their trust and loyalty.Moreover, Smt Soldering Process Factory is committed to sustainability and environmental responsibility. The company adheres to strict environmental standards and adopts eco-friendly practices in its manufacturing processes. By prioritizing sustainability, Smt Soldering Process Factory not only reduces its environmental footprint but also contributes to a greener and more sustainable future.Smt Soldering Process Factory's dedication to excellence and innovation has not gone unnoticed, as the company has received numerous accolades and certifications for its outstanding performance in the manufacturing industry. This recognition further solidifies Smt Soldering Process Factory’s position as a leader in advanced manufacturing technology.Looking ahead, Smt Soldering Process Factory is poised to continue its upward trajectory, driving innovation and setting new benchmarks in the soldering industry. With a focus on research and development, a talented team, and a commitment to customer satisfaction, the company is well-positioned to maintain its position as an industry frontrunner.In conclusion, Smt Soldering Process Factory’s journey to becoming a leader in advanced manufacturing technology is a testament to its unwavering commitment to excellence, innovation, and customer satisfaction. As the company continues to push the boundaries of technological advancement, it is poised to shape the future of the manufacturing industry and set new standards for excellence.

Top Through Hole Factories in the Market Today

Smt Through Hole Factories are a crucial part of the manufacturing process for a wide range of electronic products. These factories utilize state-of-the-art technology and equipment to produce high-quality through hole components that are used in various industries, including consumer electronics, automotive, telecommunications, and more. With a focus on precision and efficiency, these factories play an essential role in the production of modern electronics.One such company at the forefront of Smt Through Hole manufacturing is {}. With years of experience and expertise in the field, they have established themselves as a leading provider of through hole components for the electronics industry. Their commitment to quality and innovation has set them apart in the competitive manufacturing landscape, allowing them to deliver exceptional products to their clients.Founded in {}, {} has rapidly grown to become a trusted name in the Smt Through Hole manufacturing industry. Their dedication to continuous improvement and investment in cutting-edge technology has enabled them to stay ahead of the curve and meet the evolving needs of their customers. The company's manufacturing facilities are equipped with advanced machinery and quality control systems to ensure that every through hole component meets the highest standards of performance and reliability.One of the key factors that set {} apart from other Smt Through Hole factories is their emphasis on customization and flexibility. They understand that each client may have unique requirements and specifications for their through hole components, and they are committed to providing tailored solutions that meet these needs. Whether it's custom designs, specific materials, or intricate assembly processes, {} has the expertise and capabilities to deliver customized through hole components that align with their clients' exact requirements.In addition to their focus on customization, {} also places a strong emphasis on sustainability and environmental responsibility in their manufacturing processes. They have implemented eco-friendly practices and technologies to minimize their environmental footprint while optimizing the efficiency of their operations. This commitment to sustainability not only aligns with global trends towards green manufacturing but also ensures that their clients can benefit from socially responsible sourcing and production of through hole components.Furthermore, {} prides itself on its stringent quality assurance protocols and certifications. The company adheres to industry-leading quality standards and regulatory requirements to guarantee the reliability and performance of their through hole components. Their dedicated quality control teams meticulously inspect and test every product to ensure that they meet the highest standards of conformance and consistency, providing peace of mind to their clients and end-users.With a strong foundation built on innovation, customization, sustainability, and quality, {} continues to lead the way in the Smt Through Hole manufacturing industry. Their unwavering commitment to excellence and customer satisfaction has earned them a solid reputation as a preferred partner for electronic companies seeking reliable through hole components for their products. As the demand for advanced electronic devices continues to grow, {} is well-positioned to meet the increasing needs of the market and drive the industry forward with their cutting-edge solutions.In conclusion, Smt Through Hole factories play a vital role in the production of electronic products, and companies like {} are at the forefront of this essential manufacturing process. With their focus on innovation, customization, sustainability, and quality, they are well-equipped to meet the evolving demands of the electronics industry and continue to deliver outstanding through hole components to their clients. As technology continues to advance, {} remains dedicated to pushing the boundaries of Smt Through Hole manufacturing and setting new standards for excellence in the field.

Top Contract Electronics Factories to Consider for Your Manufacturing Needs

Contract Electronics Factories have become an important part of the global supply chain for electronic products. These factories provide important manufacturing and assembly services for electronics companies, allowing them to outsource their production needs and focus on other aspects of their business. One such contract electronics factory that has been making waves in the industry is Company X. Company X is a leading provider of contract manufacturing services for a wide range of electronics products. With state-of-the-art facilities and a highly skilled workforce, Company X has been able to build a reputation for delivering high-quality products and services to its clients.The global electronics industry has been growing at a rapid pace, and this has led to an increased demand for contract electronics factories. These factories play a crucial role in the production of electronic devices, from smartphones and tablets to medical devices and automotive electronics. By outsourcing their manufacturing needs to contract electronics factories, companies are able to benefit from cost efficiencies, access to advanced technologies, and greater flexibility in their production processes.Company X has been a key player in this industry, providing a wide range of services to its clients. From PCB assembly and testing to complete product assembly and packaging, Company X offers a comprehensive suite of manufacturing services to meet the diverse needs of its customers. The company has also invested heavily in research and development, allowing it to stay ahead of the curve in terms of technology and innovation.One of the key advantages of working with contract electronics factories like Company X is the ability to leverage their expertise and experience in the industry. With years of experience in manufacturing and assembly, these factories are able to provide valuable insights and recommendations to their clients, helping them optimize their production processes and improve product quality.In addition to manufacturing and assembly services, Company X also offers a range of value-added services to its clients. These include supply chain management, logistics and distribution, and aftermarket services. By offering a comprehensive suite of services, Company X is able to provide end-to-end solutions to its clients, helping them streamline their operations and reduce time-to-market for their products.Another important aspect of working with contract electronics factories is the ability to scale production quickly and efficiently. With the global electronics market constantly evolving, companies need to be able to adapt to changes in demand and market conditions. By working with a contract electronics factory like Company X, companies are able to access flexible production capacity and resources, allowing them to scale production up or down as needed.Company X has also placed a strong emphasis on quality and compliance in its manufacturing processes. The company has implemented rigorous quality control measures and certification processes to ensure that its products meet the highest standards of reliability and performance. This commitment to quality has helped Company X build strong relationships with its customers and establish itself as a trusted partner in the industry.As the global electronics industry continues to grow and evolve, the role of contract electronics factories like Company X will only become more important. With their expertise, resources, and commitment to quality, these factories are well positioned to help electronics companies navigate the complex challenges of today's market and achieve success in their manufacturing operations.In conclusion, contract electronics factories play a crucial role in the global supply chain for electronic products. With their manufacturing and assembly services, as well as their expertise and resources, these factories help companies streamline their operations, improve product quality, and navigate the complexities of the electronics industry. Company X is a prime example of a leading contract electronics factory that is well positioned to meet the diverse needs of its clients and contribute to the continued growth and success of the global electronics market.

Top 5 EMS Manufacturers in the Market Today

Ems Manufacturer, a leading provider of electronic manufacturing services, has announced a major expansion of its production capabilities. The company, known for its high-quality and reliable electronic products, has invested in state-of-the-art technology to enhance its manufacturing capabilities and meet the growing demand for electronic products in the global market.With over 20 years of experience in the industry, Ems Manufacturer has built a solid reputation for delivering innovative and cost-effective electronic manufacturing solutions to a wide range of industries including automotive, aerospace, healthcare, telecommunications, and consumer electronics. The company's commitment to quality, efficiency, and customer satisfaction has made it a preferred partner for many leading brands and OEMs.The recent expansion of Ems Manufacturer's production capabilities is aimed at further strengthening its position in the market and catering to the evolving needs of its diverse customer base. The company has invested in advanced equipment and technology to improve its manufacturing processes and increase production capacity. This strategic investment will enable Ems Manufacturer to take on larger and more complex projects, while maintaining its high standards of quality and reliability.In addition to the technological advancements, Ems Manufacturer has also expanded its facilities to accommodate the growing demand for its services. The company has added new production lines and has increased its workforce to ensure seamless and efficient operations. By investing in its infrastructure, Ems Manufacturer aims to become a more responsive and flexible manufacturing partner for its customers, offering shorter lead times and faster time-to-market for their electronic products."We are excited to announce this significant expansion of our production capabilities," said the CEO of Ems Manufacturer. "This investment reaffirms our commitment to delivering the best-in-class electronic manufacturing services to our customers. With the new technology and expanded facilities, we are well-equipped to meet the evolving needs of the market and continue to provide innovative and reliable solutions to our clients."The expansion of Ems Manufacturer's production capabilities comes at a time when the demand for electronic products is on the rise across various industries. With the increasing proliferation of smart devices, IoT technologies, and electric vehicles, there is a growing need for high-quality and advanced electronic components and assemblies. Ems Manufacturer is well-positioned to capitalize on this trend and support its customers in bringing their innovative products to the market.As a trusted electronic manufacturing partner, Ems Manufacturer is committed to upholding the highest standards of quality, efficiency, and reliability in all aspects of its operations. The company's ISO-certified manufacturing facilities and rigorous quality control processes ensure that every product that leaves its facility meets the strictest industry standards. Furthermore, Ems Manufacturer places a strong emphasis on sustainability and environmental responsibility, implementing eco-friendly practices and processes throughout its operations.With its expanded production capabilities and unwavering commitment to excellence, Ems Manufacturer is poised to continue its growth trajectory and solidify its position as a leading provider of electronic manufacturing services in the global market. The company's ability to adapt to the changing needs of the industry and its relentless focus on customer satisfaction are key factors driving its success and earning the trust of its customers.In conclusion, Ems Manufacturer's recent expansion of its production capabilities marks a significant milestone in its journey to becoming a leading player in the electronic manufacturing industry. With its investment in advanced technology, expanded facilities, and a strong commitment to quality and customer satisfaction, Ems Manufacturer is well-equipped to meet the evolving needs of the market and support its customers in bringing their innovative electronic products to life.

Quality Pcb Service for Energy Applications

Energy PCB Service, a leading provider of printed circuit board (PCB) manufacturing and assembly services, has announced its latest expansion to further meet the needs of the energy industry. The company is known for its high-quality PCB solutions that meet the rigorous demands of the energy sector, and its latest move builds upon its commitment to providing reliable and efficient products to its customers.With over [number] years of experience in the PCB industry, Energy PCB Service has established itself as a trusted partner for companies in the energy field. The company’s extensive knowledge and expertise in PCB manufacturing and assembly have allowed it to become a go-to source for high-quality solutions that meet the exacting standards of the energy industry.Energy PCB Service’s latest expansion comes at a time when the demand for reliable and efficient energy solutions is at an all-time high. As the industry continues to evolve and innovate, there is a growing need for PCBs that can withstand the harsh conditions and rigorous requirements of energy applications. With its new expansion, Energy PCB Service aims to address this need by offering an even wider range of products and services tailored to the specific needs of energy companies.One of the key highlights of the expansion is Energy PCB Service’s investment in state-of-the-art manufacturing and assembly technology. This investment will allow the company to further enhance its capabilities and improve the quality and reliability of its products. By leveraging the latest technology, Energy PCB Service aims to stay at the forefront of innovation and continue to provide cutting-edge solutions to its customers.In addition to its technological investment, Energy PCB Service has also expanded its team of experts to include more professionals with specialized knowledge in the energy sector. This move is part of the company’s commitment to understanding and addressing the unique challenges and requirements of energy applications. By having a team of experts dedicated to the energy industry, Energy PCB Service can better serve its customers and provide tailored solutions that meet their specific needs.“We are excited to announce our latest expansion, which underscores our commitment to providing the best PCB solutions for the energy industry,” said [Spokesperson], [Title] at Energy PCB Service. “With our investment in cutting-edge technology and our growing team of experts, we are well-equipped to meet the evolving needs of our customers in the energy sector. Our goal is to continue to be a trusted partner for energy companies, providing them with the high-quality PCB products and services they need to succeed.”Energy PCB Service’s expansion is expected to benefit a wide range of companies in the energy industry, including those involved in renewable energy, oil and gas, power generation, and more. By offering a comprehensive range of PCB solutions, the company aims to support the development and deployment of energy technologies that are essential for a sustainable and efficient future.As Energy PCB Service continues to expand its presence in the energy sector, its focus remains on delivering top-quality products and services that exceed customer expectations. The company’s commitment to innovation, reliability, and customer satisfaction positions it as a leader in the PCB industry, and its latest expansion reinforces its dedication to serving the unique needs of the energy industry. With its investment in technology and expertise, Energy PCB Service is well-positioned to continue providing top-tier PCB solutions that drive the success of its customers in the energy sector.

Professional PCB Design and Assembly Services in China

China PCB Design and Assembly, a leading electronic manufacturing service provider, has been making waves in the industry with its high-quality PCB design and assembly solutions. With a commitment to delivering cutting-edge technology and unmatched customer service, the company has earned a reputation for excellence in the electronic manufacturing sector.China PCB Design and Assembly specializes in providing innovative and reliable PCB design and assembly services for a wide range of industries, including telecommunications, automotive, medical, consumer electronics, and more. The company has a team of experienced engineers and technicians who are dedicated to ensuring that every project meets the highest standards of quality and performance.One of the key factors that sets China PCB Design and Assembly apart from its competitors is its state-of-the-art manufacturing facilities. The company has invested in advanced technology and equipment to streamline the production process and deliver superior results for its clients. With a focus on continuous improvement and innovation, China PCB Design and Assembly is able to meet the evolving needs of the electronic manufacturing industry.In addition to its advanced manufacturing capabilities, China PCB Design and Assembly is also committed to providing exceptional customer service. The company works closely with each client to understand their specific requirements and deliver customized solutions that meet their unique needs. From the initial design phase to final assembly and testing, China PCB Design and Assembly is dedicated to providing a seamless and efficient experience for its clients.Furthermore, China PCB Design and Assembly is also committed to sustainability and environmental responsibility. The company has implemented strict quality control and environmental management systems to minimize its impact on the environment and ensure that its operations are as eco-friendly as possible. With a focus on corporate social responsibility, China PCB Design and Assembly is dedicated to making a positive impact on the communities and environments in which it operates.As a result of its unwavering commitment to excellence, China PCB Design and Assembly has earned the trust and confidence of leading companies in the electronic manufacturing industry. The company has a proven track record of delivering high-quality PCB design and assembly solutions that meet the stringent demands of its clients. Whether it’s a complex telecommunications project or a cutting-edge automotive application, China PCB Design and Assembly has the expertise and capabilities to deliver exceptional results.Looking ahead, China PCB Design and Assembly is poised to continue its growth and leadership in the electronic manufacturing sector. With a focus on continuous improvement, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the industry. By staying at the forefront of technology and industry trends, China PCB Design and Assembly will continue to deliver unparalleled value and service to its clients.In conclusion, China PCB Design and Assembly is a trusted and respected electronic manufacturing service provider that is dedicated to delivering high-quality PCB design and assembly solutions. With a focus on advanced technology, superior customer service, and environmental responsibility, the company has earned a reputation for excellence in the industry. As a leader in the electronic manufacturing sector, China PCB Design and Assembly is well-equipped to meet the evolving needs of its clients and drive the industry forward.

Optimizing High Volume Production for Efficiency and Scale

High Volume Production Fuels Growth for Leading Manufacturing CompanyWith the increasing demand for consumer goods, the manufacturing industry has been experiencing significant growth in recent years. As consumers continue to seek out high-quality products at affordable prices, manufacturing companies are faced with the challenge of meeting this demand while maintaining efficient production processes. One company that has successfully risen to this challenge is {}.{} is a leading manufacturer of consumer goods, specializing in the production of a wide range of products including electronics, home appliances, and personal care items. The company has built a solid reputation for delivering high-quality products to its customers, and its commitment to innovative production methods has been a key driver of its success.One of the company's most notable achievements is its high volume production capabilities, which have enabled {} to meet the growing demand for its products. By investing in state-of-the-art manufacturing technology and implementing streamlined production processes, the company has been able to significantly increase its output while maintaining consistently high product quality.In a recent interview, {}'s CEO, John Smith, spoke about the company's approach to high volume production. "Our goal has always been to provide our customers with the best products possible, and that means we need to be able to produce them at a high volume," said Smith. "Investing in advanced manufacturing technology and optimizing our production processes has allowed us to achieve this, and it has been a driving force behind our company's growth."The company's dedication to high volume production has not only benefited its customers, but has also had a positive impact on its overall business performance. By increasing its production capacity, {} has been able to expand its market reach and take advantage of new business opportunities. This, in turn, has contributed to the company's revenue growth and solidified its position as a key player in the manufacturing industry.In addition to its high volume production capabilities, {} has also set itself apart with its commitment to sustainability. The company has made significant strides in reducing its environmental impact through the implementation of eco-friendly production practices and the use of sustainable materials. This focus on sustainability has not only resonated with environmentally conscious consumers, but has also positioned {} as a responsible and forward-thinking manufacturing company.Looking ahead, {} is poised to continue its growth trajectory as it further expands its high volume production capabilities. The company has plans to invest in new production technology and expand its manufacturing facilities in order to meet the increasing demand for its products. Additionally, {} is exploring opportunities to diversify its product range and enter new markets, setting the stage for even more growth and success in the future.As the manufacturing industry continues to evolve and adapt to changing consumer preferences, companies like {} are leading the way with their innovative production methods and commitment to quality. By prioritizing high volume production and embracing sustainability, {} has solidified its position as a trusted manufacturer and is well-positioned for continued success in the years to come.In conclusion, high volume production has been a driving force behind {}'s growth, enabling the company to meet increasing demand for its products, expand its market reach, and drive revenue growth. As {} continues to invest in advanced manufacturing technology and sustainable practices, it is poised to maintain its position as a leader in the manufacturing industry and drive further success in the future.

High-quality Low Volume PCB Assembly Services in China

China PCB Assembly Low VolumeShenzhen, China – With the rising demand for high-quality PCB assembly and manufacturing, China has positioned itself as a global leader in this industry. One such company that has been making waves in the field of low volume PCB assembly is Shenzhen [Removed Brand Name]. This company has been at the forefront of providing innovative solutions for low volume PCB assembly, catering to the diverse needs of its global clientele.[Removed Brand Name] is a leading PCB assembly manufacturer in China, specializing in low volume PCB assembly. With state-of-the-art facilities and a dedicated team of experienced engineers, the company prides itself on delivering high-quality PCB assembly services to its customers. The company's commitment to excellence and continuous improvement has made it a preferred choice for clients across various industries, including telecommunications, consumer electronics, medical devices, and automotive.The company's low volume PCB assembly services are designed to meet the unique requirements of customers who need small to medium batch production runs. Whether it's a prototype, a pilot run, or a small-scale production, [Removed Brand Name] is equipped to handle a wide range of low volume PCB assembly projects with precision and efficiency. The company understands the importance of quick turnaround times and flexible manufacturing solutions for low volume production, and it has continually invested in cutting-edge technologies and streamlined processes to meet these demands.In addition to its state-of-the-art manufacturing facilities, [Removed Brand Name] also offers comprehensive PCB assembly services, including component sourcing, PCB fabrication, surface-mount technology (SMT) assembly, through-hole assembly, testing, and quality inspection. The company's end-to-end solutions ensure that customers receive fully assembled PCBs that meet the highest quality standards and performance requirements.[Removed Brand Name] is committed to maintaining strict quality control throughout the PCB assembly process. The company adheres to international quality standards and certifications to ensure that every assembled PCB meets the highest quality and reliability standards. From raw material inspection to final product testing, [Removed Brand Name] employs rigorous quality control measures to deliver flawless PCB assemblies to its clients.Furthermore, [Removed Brand Name] places a strong emphasis on customer satisfaction and long-term partnerships. The company works closely with its clients to understand their specific requirements, and its team of engineers and technical experts provides professional guidance and support at every stage of the PCB assembly process. This customer-centric approach has earned [Removed Brand Name] a reputation for reliability, responsiveness, and excellence in the PCB assembly industry.As the demand for low volume PCB assembly continues to grow, companies like [Removed Brand Name] are playing a crucial role in meeting the evolving needs of the global electronics market. With its focus on quality, innovation, and customer service, [Removed Brand Name] is well-positioned to lead the way in providing cutting-edge PCB assembly solutions to clients worldwide.In conclusion, [Removed Brand Name] has established itself as a trusted partner for low volume PCB assembly, delivering reliable, high-quality, and cost-effective solutions to meet the diverse needs of its global clientele. With its state-of-the-art facilities, comprehensive services, and customer-centric approach, [Removed Brand Name] is poised to continue making significant contributions to the PCB assembly industry in China and beyond.

Top Pcb Assembly Factory for Quality Electronics Manufacturing

Pcb Assembly Firm Factory, a leading provider of electronic manufacturing services, recently announced the expansion of their facility to accommodate the increasing demand for their services. This expansion comes as a response to the growing need for high-quality PCB assembly from a diverse range of industries.Located in [location], Pcb Assembly Firm Factory has been in the business for over [number] years, providing top-notch PCB assembly and electronic manufacturing solutions to their clients. The company prides itself on its state-of-the-art facility, cutting-edge technology, and a team of highly skilled professionals who are dedicated to delivering exceptional results.The expansion of their facility is an exciting development for Pcb Assembly Firm Factory, as it will allow them to take on larger projects and meet the needs of a broader client base. With the additional space and resources, the company will be able to increase its production capacity and improve efficiency, ultimately providing a faster turnaround for their clients without compromising on quality.In addition to the physical expansion of their facility, Pcb Assembly Firm Factory has also invested in new equipment and technology to further enhance their capabilities. This includes the latest in PCB assembly machinery, testing equipment, and quality control systems, ensuring that they can meet the stringent requirements of even the most complex projects.With these advancements, Pcb Assembly Firm Factory is well-positioned to continue providing innovative and reliable electronic manufacturing solutions. Whether it's a small prototype run or a large-scale production order, the company is committed to delivering excellence at every stage of the process.Furthermore, Pcb Assembly Firm Factory places a strong emphasis on customer satisfaction and building long-term relationships with their clients. They understand the importance of clear communication, collaboration, and flexibility when working on projects, and strive to provide a seamless experience from start to finish.The expansion of their facility is just one example of Pcb Assembly Firm Factory's dedication to staying at the forefront of the electronic manufacturing industry. As technology continues to evolve, the company is focused on staying ahead of the curve and adapting to the changing needs of their clients.In light of this expansion, Pcb Assembly Firm Factory is also looking to add to their team, creating new job opportunities within the community. The company is committed to providing a supportive and rewarding work environment, and they are excited about the prospect of bringing on new talent to help drive their continued growth and success.Overall, the expansion of their facility marks a significant milestone for Pcb Assembly Firm Factory. It not only reflects the company's commitment to meeting the increasing demand for their services but also represents their ongoing dedication to innovation, efficiency, and customer satisfaction.As Pcb Assembly Firm Factory looks toward the future, they remain focused on delivering the highest quality PCB assembly and electronic manufacturing services to their clients, while continuing to push the boundaries of what is possible in the industry. The company is confident that their expanded facility and enhanced capabilities will further solidify their position as a leader in the electronic manufacturing sector, and they are excited about the opportunities that lie ahead.

High-Quality Medical Electronics Manufacturing: A Look Inside a Leading Factory

Medical Electronics Factory (MEF) today announced the grand opening of its state-of-the-art manufacturing facility, marking a significant milestone in the company's commitment to producing high-quality medical electronics products. The new facility, located in the heart of Silicon Valley, is equipped with cutting-edge technology and is set to become a center for innovation in the medical electronics industry.MEF has been a leading player in the medical electronics market for over two decades, specializing in the design and manufacturing of a wide range of medical devices and equipment. With a focus on innovation and quality, the company has gained a reputation for delivering reliable and advanced technology to healthcare professionals and patients around the world.The new manufacturing facility is a testament to MEF's dedication to meeting the growing demand for medical electronics products. With a sprawling campus covering over 100,000 square feet, the facility is designed to streamline the production process and enhance efficiency. It is equipped with the latest automated production lines, precision manufacturing equipment, and advanced quality control systems to ensure that every product meets the highest standards."We are thrilled to announce the opening of our new manufacturing facility, which represents a significant investment in the future of medical electronics," said John Smith, CEO of MEF. "This state-of-the-art facility will enable us to ramp up production, improve our turnaround times, and continue to deliver innovative and reliable products to our customers."The facility is also designed with sustainability in mind, incorporating energy-efficient systems and environmentally friendly practices. MEF has made a commitment to minimizing its environmental impact and ensuring that its operations are in line with the latest industry standards for sustainability.In addition to its manufacturing capabilities, the new facility includes research and development labs where MEF's team of engineers and scientists will work to develop next-generation medical electronics products. These facilities will play a crucial role in driving innovation and pushing the boundaries of what is possible in the medical electronics industry."We believe that innovation is the key to success in the medical electronics market," said Dr. Sarah Johnson, Chief Technology Officer at MEF. "Our new research and development labs will serve as a hub for creativity and collaboration, enabling us to develop new technologies that will have a positive impact on patient care and healthcare outcomes."The opening of the new facility has also created numerous job opportunities in the area, with MEF hiring a large number of skilled workers and professionals to support its operations. The company is committed to providing a safe and inclusive work environment, and it has implemented strict safety protocols to protect its employees and visitors.MEF's new manufacturing facility represents a major step forward for the company and the medical electronics industry as a whole. With its commitment to quality, innovation, and sustainability, MEF is set to continue making a lasting impact on the healthcare sector and improving the lives of patients around the world.