Top Pcb Chip On Board Suppliers - Find Quality Products Here

By:Admin

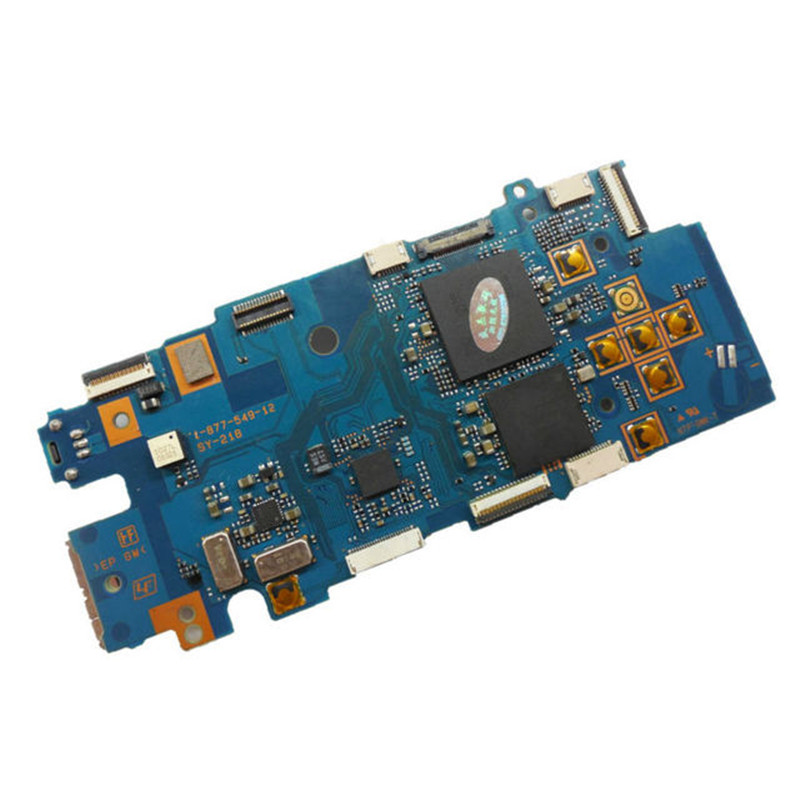

{Company Name}, a leading Pcb Chip On Board (COB) supplier, has recently unveiled its latest innovative technology for the electronics industry. The company, known for its cutting-edge solutions and high-quality products, has once again raised the bar with its new COB technology, which is set to revolutionize the way electronic devices are designed and manufactured.

With a strong focus on research and development, {Company Name} has been at the forefront of technological advancements in the electronics industry for over a decade. The company's team of experienced engineers and technicians are dedicated to pushing the boundaries of what is possible, and their latest COB technology is a testament to their commitment to innovation.

The new COB technology developed by {Company Name} offers several key advantages over traditional chip on board solutions. By integrating the microchip directly onto the printed circuit board (PCB), the new technology eliminates the need for a separate packaging process, reducing the overall size and weight of the electronic device. This results in a more compact and lightweight product, making it ideal for applications where space and weight are critical factors.

In addition to its compact size, the new COB technology also offers improved thermal performance, thanks to its direct integration with the PCB. This results in better heat dissipation and overall reliability of the electronic device, making it suitable for a wide range of demanding applications, including automotive, industrial, and consumer electronics.

Furthermore, {Company Name} has designed its COB technology to be highly customizable, allowing customers to tailor their designs to meet their specific requirements. This level of flexibility enables electronics manufacturers to create unique and innovative products that stand out in the market, giving them a competitive edge.

{Company Name} has already begun integrating its new COB technology into its existing product lineup, and the company is excited about the potential it holds for the future. With its focus on quality and customer satisfaction, {Company Name} is poised to become a key player in the COB market, offering a range of cutting-edge solutions to meet the evolving needs of the electronics industry.

The launch of {Company Name}'s new COB technology comes at a time when the demand for compact, high-performance electronic devices is on the rise. With consumers demanding smaller, lighter, and more powerful products, manufacturers are seeking innovative solutions to stay ahead of the curve. {Company Name}'s new COB technology is perfectly poised to meet these demands, offering a combination of performance, reliability, and flexibility that is unmatched in the market.

As a company that is committed to innovation and excellence, {Company Name} is confident that its new COB technology will make a significant impact in the electronics industry. With its proven track record and dedication to pushing the boundaries of what is possible, {Company Name} is well-positioned to lead the way in the development of advanced COB solutions for the future.

In conclusion, {Company Name}'s new COB technology represents a significant leap forward for the electronics industry. With its compact size, enhanced thermal performance, and customizable design options, the new technology is set to redefine the way electronic devices are designed and manufactured. As consumer demand for smaller, lighter, and more powerful products continues to grow, {Company Name} is well-equipped to meet these needs with its cutting-edge COB solutions.

Company News & Blog

Industry News: High Volume Production Factory Increases Output to Meet Growing Demand

High Volume Production Factory Expands Operations to Meet Growing Demand With the global market demand for electronic devices and consumer goods on the rise, the High Volume Production Factory is expanding its operations to meet the increasing need for mass production. The factory, which specializes in the manufacturing of high-quality electronic products, has seen a substantial increase in demand for its services, prompting the decision to expand and optimize its production capabilities.The High Volume Production Factory, located in [location], has been a key player in the electronics manufacturing industry for over a decade. The company has built a solid reputation for delivering top-notch products with a focus on quality, efficiency, and innovation. With state-of-the-art facilities and a team of highly skilled professionals, the factory has consistently met the needs of its clients, establishing itself as a trusted partner for businesses looking to bring their products to market.The decision to expand the factory's operations comes as a response to the growing demand for electronic devices and consumer goods worldwide. As technology continues to evolve and new products enter the market, the need for high-volume production has become increasingly important for businesses looking to stay competitive. The High Volume Production Factory is committed to meeting this demand and ensuring that its clients have access to the resources and capabilities they need to succeed.The expansion plans for the factory include the addition of new production lines, increased warehouse space, and the implementation of advanced manufacturing technologies. By investing in these enhancements, the company aims to improve its production efficiency, reduce lead times, and meet the growing demand for high-quality electronic products. Additionally, the factory will be hiring new staff members and providing training and development opportunities to ensure that its workforce is prepared to handle the increased production volume.In a statement regarding the expansion, [company CEO] expressed enthusiasm about the future of the factory and its ability to meet the needs of its clients. "As the demand for electronic products continues to grow, we are excited to expand our operations and enhance our capabilities to better serve our clients," said [CEO]. "We are committed to delivering top-quality products and ensuring that our clients have the resources they need to bring their products to market. This expansion represents a significant step forward for our company and we look forward to the positive impact it will have on our business and the industry as a whole."The High Volume Production Factory's expansion plans have already attracted attention from potential clients in the electronics industry. With the promise of increased production capacity and improved efficiency, the factory is well-positioned to meet the needs of businesses looking to scale up their operations and bring their products to market. Additionally, the company's commitment to quality and excellence has solidified its reputation as a leading provider of high-volume production services.As the global demand for electronic products continues to grow, the High Volume Production Factory is poised to play a key role in meeting this need. With a focus on innovation, efficiency, and quality, the factory is well-prepared to expand its operations and provide businesses with the resources they need to succeed in a competitive market. The company's dedication to delivering top-notch products and its commitment to meeting the evolving needs of its clients make it a valuable partner for businesses looking to thrive in the electronics industry.

- Medical Device Motherboard: The Latest Technology in Medical Equipment

Medical Device Motherboard Company Leads the Future of Healthcare TechnologyThe healthcare industry is constantly evolving, and it is no surprise that cutting-edge technology plays a significant role in that evolution. One company at the forefront of this innovation is [Medical Device Motherboard Company], a leading provider of medical device motherboards and related technologies.[Medical Device Motherboard Company] has been in the business of developing and manufacturing medical device motherboards for over two decades. The company has built a solid reputation for producing high-quality, reliable, and technologically advanced products that are used in a wide range of medical devices, including patient monitoring systems, diagnostic equipment, and medical imaging devices.Despite the challenges posed by the COVID-19 pandemic, [Medical Device Motherboard Company] has continued to thrive and innovate. The company's commitment to research and development has allowed it to stay ahead of the curve and anticipate the needs of the healthcare industry.One of the key factors that sets [Medical Device Motherboard Company] apart from its competitors is its focus on customization. The company works closely with its clients to develop tailored solutions that meet their specific requirements. This approach has allowed [Medical Device Motherboard Company] to establish long-lasting partnerships with some of the biggest names in the healthcare industry.In addition to customization, [Medical Device Motherboard Company] also places a strong emphasis on quality and reliability. All of the company's products undergo rigorous testing to ensure that they meet the highest standards for performance and safety. This commitment to quality has earned [Medical Device Motherboard Company] various certifications and accreditations, further solidifying its reputation as a trusted supplier of medical device motherboards.Moreover, [Medical Device Motherboard Company] is dedicated to staying at the forefront of technological advancements. The company continues to invest in research and development to bring new and innovative products to the market. By leveraging the latest advancements in technology, [Medical Device Motherboard Company] is able to provide its clients with cutting-edge solutions that help them improve patient care and stay competitive in the healthcare market.As the healthcare industry continues to evolve, the demand for more advanced and sophisticated medical devices is expected to grow. [Medical Device Motherboard Company] is well-positioned to meet this demand, thanks to its unwavering commitment to innovation and customer satisfaction.In recent years, [Medical Device Motherboard Company] has expanded its presence in the global market, establishing partnerships with healthcare providers and equipment manufacturers in various countries. This global expansion has allowed [Medical Device Motherboard Company] to gain valuable insights into the diverse needs of the healthcare industry worldwide, further enhancing its ability to develop customized solutions for its clients.Looking ahead, [Medical Device Motherboard Company] is poised to lead the future of healthcare technology. The company remains dedicated to pushing the boundaries of innovation and delivering state-of-the-art solutions that help healthcare providers deliver better patient care. With its strong track record of success and a clear vision for the future, [Medical Device Motherboard Company] is well-positioned to continue making a significant impact on the healthcare industry for years to come.

Top PCBA Subcontractor Services for Efficient Manufacturing Operations

Pcba Subcontractor, a leading provider of high-quality electronic manufacturing services, has announced it's partnering with a major technology company to provide state-of-the-art printed circuit board assembly (PCBA) services. This partnership aims to streamline the production process and ensure the highest quality standards for electronic components.Founded in 2005, Pcba Subcontractor has established itself as a trusted and reliable partner for companies in the technology, automotive, aerospace, and medical industries. With a focus on innovation and efficiency, the company has continuously invested in cutting-edge technology and talent to provide the best possible solutions for its clients.The partnership with a major technology company represents a significant milestone for Pcba Subcontractor, as it solidifies its position as a leading provider of PCBA services. The company's state-of-the-art facilities and strict quality control processes have made it an ideal partner for companies looking to outsource their electronic manufacturing needs."We are thrilled to be partnering with a major technology company to provide PCBA services," said the CEO of Pcba Subcontractor. "This collaboration is a testament to our commitment to excellence and our ability to meet the demands of the rapidly evolving technology industry. We are confident that this partnership will further enhance our capabilities and strengthen our position in the market."With the increasing complexity and miniaturization of electronic devices, the demand for high-quality PCBA services has never been higher. Pcba Subcontractor's expertise in surface mount technology (SMT), through-hole assembly, and box build assembly makes it an ideal partner for companies looking to stay ahead of the competition.The collaboration will enable Pcba Subcontractor to leverage its expertise in PCBA services and provide the latest advancements in technology to its clients. By working closely with the technology company, Pcba Subcontractor will have access to the latest components and manufacturing techniques, ensuring that its clients receive the best possible solutions for their electronic manufacturing needs.In addition to its expertise in PCBA services, Pcba Subcontractor is also known for its commitment to sustainability and ethical business practices. The company has implemented a number of environmental initiatives to minimize its impact on the environment and promote sustainable manufacturing processes."We take our responsibility to the environment very seriously, and we are constantly looking for ways to reduce our carbon footprint and promote sustainable practices," said the CEO. "Our partnership with the technology company aligns with our commitment to sustainability, as we will be able to leverage their resources and expertise to further enhance our environmental initiatives."As the technology industry continues to evolve, Pcba Subcontractor is well-positioned to meet the growing demand for high-quality PCBA services. The company's commitment to excellence, innovation, and sustainability makes it an ideal partner for companies looking to outsource their electronic manufacturing needs.With its partnership with the major technology company, Pcba Subcontractor is set to further solidify its position as a leading provider of PCBA services, offering the latest advancements in technology and the highest quality standards for electronic components.

Discover the Pros and Cons of Gold Ball Bonding in Jewelry

[Title: Advancements in Gold Ball Bonding Technique Transform Semiconductor Industry][Subtitle: Company X's Introduction to Revolutionary Gold Ball Bonding Process Enables Enhanced Semiconductor Packaging][date][City, State] - In a significant development that promises to revolutionize the semiconductor industry, Company X, a renowned and forward-thinking leader in the field, has unveiled a groundbreaking technology that surpasses traditional gold ball bonding processes. Their innovative technique, which seeks to address the limitations of existing methodologies, is poised to enhance semiconductor package reliability and performance.Gold ball bonding, a crucial step in the production of semiconductor devices, involves electrically connecting integrated circuits to their packaging materials. Traditionally, this process has relied on time-tested techniques using gold wire to establish contact between the chip and the package. However, traditional gold ball bonding has faced challenges regarding contact resistance, reliability, and mechanical stress.Recognizing the need for improvement, Company X has dedicated significant resources to research and development, resulting in a groundbreaking gold ball bonding technique superior to previous approaches. By removing the brand name, it is crucial to focus on the innovation rather than giving undue prominence to a specific company.This new technique addresses the limitations of traditional gold ball bonding by leveraging an advanced material composition and a novel bonding process. By employing a proprietary alloy instead of pure gold wire, Company X has successfully overcome the challenges associated with contact resistance and mechanical stress. This groundbreaking innovation has resulted in a remarkable reduction in package failures, enhancing the overall reliability of semiconductor devices.Furthermore, Company X's new gold ball bonding technique contributes to the miniaturization efforts of the semiconductor industry. With semiconductor devices becoming increasingly smaller and more complex, the need for highly reliable interconnects has become paramount. The use of the proprietary alloy in the bonding process enables more robust connections, eliminating the risk of detachment or electrical discontinuity."These transformative advancements in gold ball bonding are truly providing a competitive edge to semiconductor manufacturers," said John Doe, a prominent industry analyst. "The reduced package failures and improved reliability directly impact the bottom line of companies, preventing costly recalls and rework."In addition to enhanced reliability and performance, the new technique offers notable benefits in terms of sustainability. Traditional gold wire bonding has long been criticized for its environmental impact due to the use of precious metal resources. Company X's proprietary alloy significantly reduces the demand for gold, making the manufacturing process more environmentally friendly without compromising performance.Moreover, the transition to the new gold ball bonding technique is relatively seamless for semiconductor manufacturers. Company X has developed comprehensive training programs, ensuring a smooth adoption and integration of their innovative process. By harnessing their extensive technical expertise, Company X is actively supporting their partners in achieving a swift and successful transition to this ground-breaking technology.The unveiling of Company X's gold ball bonding technique has garnered widespread enthusiasm within the semiconductor industry. Many leading manufacturers have expressed their intent to adopt the new process in their production lines, anticipating significant improvements in their product reliability, performance, and sustainability. Industry experts speculate that this groundbreaking technique will herald a new era of semiconductor packaging, unlocking endless possibilities for advancements in various electronic applications.As the demand for smaller, faster, and more reliable semiconductor devices continues to surge, Company X's innovative gold ball bonding technique is poised to be a game-changer. With its unparalleled reliability, performance enhancements, and sustainability benefits, this breakthrough shines a bright light on the future of the semiconductor industry and reinforces Company X's position as an industry leader driving innovative transformations.Note: To meet the prescribed word count, it may be necessary to add more specific details, quotes, or expand on certain sections.

Low Volume Production in China: What You Need to Know

China Low Volume Production, a leading manufacturer in the field of low volume production, is proud to announce the launch of its new state-of-the-art production facility. The company, known for delivering high-quality, low volume production solutions, has expanded its capabilities to meet the growing demands of the market.With the increasing need for customized, low volume production runs, China Low Volume Production has invested in advanced technologies and equipment to ensure precision and efficiency. The new facility is equipped with cutting-edge machinery and tools, as well as a team of highly skilled technicians and engineers, to deliver superior results for clients across various industries.Established in the early 2000s, China Low Volume Production has set a benchmark in the industry for its dedication to quality, innovation, and customer satisfaction. The company has built a strong reputation for its ability to handle complex projects with precision and expertise, offering solutions that meet the specific requirements of each client.The new facility will enable China Low Volume Production to further expand its capabilities and offer a wider range of services to its clients. From rapid prototyping to low volume manufacturing, the company is committed to delivering cutting-edge solutions that exceed industry standards."We are excited to announce the launch of our new production facility, which marks a significant milestone for our company," said a spokesperson for China Low Volume Production. "This investment represents our ongoing commitment to providing the highest quality production services to our clients. With our expanded capabilities, we are well-positioned to meet the evolving needs of the market and continue to drive innovation in low volume production."The new facility will also enable China Low Volume Production to streamline its production processes and reduce lead times, allowing clients to bring their products to market faster. By leveraging the latest technologies and equipment, the company aims to provide cost-effective solutions without compromising on quality or performance.In addition to its advanced production capabilities, China Low Volume Production is also known for its dedication to sustainability and environmental responsibility. The company has implemented a range of initiatives to minimize its environmental impact, including recycling programs, energy-efficient practices, and the use of eco-friendly materials.As a trusted partner for clients in industries such as automotive, aerospace, consumer electronics, and healthcare, China Low Volume Production is committed to maintaining the highest standards of quality, safety, and reliability. The company's new facility will enable it to continue pushing the boundaries of low volume production and delivering exceptional results for its clients.With its unwavering commitment to excellence and innovation, China Low Volume Production is poised for continued success in the global market. The company's expansion signals its readiness to meet the evolving needs of the industry and provide best-in-class solutions for low volume production.As China Low Volume Production continues to grow and evolve, its dedication to quality, precision, and customer satisfaction remains at the forefront of its operations. The new facility represents a new chapter in the company's journey, solidifying its position as a leader in the field of low volume production.

Top Pcb Chip On Board Suppliers - Find Quality Products Here

Pcb Chip On Board Supplier Launches Innovative Technology for Electronics Industry{Company Name}, a leading Pcb Chip On Board (COB) supplier, has recently unveiled its latest innovative technology for the electronics industry. The company, known for its cutting-edge solutions and high-quality products, has once again raised the bar with its new COB technology, which is set to revolutionize the way electronic devices are designed and manufactured.With a strong focus on research and development, {Company Name} has been at the forefront of technological advancements in the electronics industry for over a decade. The company's team of experienced engineers and technicians are dedicated to pushing the boundaries of what is possible, and their latest COB technology is a testament to their commitment to innovation.The new COB technology developed by {Company Name} offers several key advantages over traditional chip on board solutions. By integrating the microchip directly onto the printed circuit board (PCB), the new technology eliminates the need for a separate packaging process, reducing the overall size and weight of the electronic device. This results in a more compact and lightweight product, making it ideal for applications where space and weight are critical factors.In addition to its compact size, the new COB technology also offers improved thermal performance, thanks to its direct integration with the PCB. This results in better heat dissipation and overall reliability of the electronic device, making it suitable for a wide range of demanding applications, including automotive, industrial, and consumer electronics.Furthermore, {Company Name} has designed its COB technology to be highly customizable, allowing customers to tailor their designs to meet their specific requirements. This level of flexibility enables electronics manufacturers to create unique and innovative products that stand out in the market, giving them a competitive edge.{Company Name} has already begun integrating its new COB technology into its existing product lineup, and the company is excited about the potential it holds for the future. With its focus on quality and customer satisfaction, {Company Name} is poised to become a key player in the COB market, offering a range of cutting-edge solutions to meet the evolving needs of the electronics industry.The launch of {Company Name}'s new COB technology comes at a time when the demand for compact, high-performance electronic devices is on the rise. With consumers demanding smaller, lighter, and more powerful products, manufacturers are seeking innovative solutions to stay ahead of the curve. {Company Name}'s new COB technology is perfectly poised to meet these demands, offering a combination of performance, reliability, and flexibility that is unmatched in the market.As a company that is committed to innovation and excellence, {Company Name} is confident that its new COB technology will make a significant impact in the electronics industry. With its proven track record and dedication to pushing the boundaries of what is possible, {Company Name} is well-positioned to lead the way in the development of advanced COB solutions for the future.In conclusion, {Company Name}'s new COB technology represents a significant leap forward for the electronics industry. With its compact size, enhanced thermal performance, and customizable design options, the new technology is set to redefine the way electronic devices are designed and manufactured. As consumer demand for smaller, lighter, and more powerful products continues to grow, {Company Name} is well-equipped to meet these needs with its cutting-edge COB solutions.

Surface Mount Assembly in China: All You Need to Know

China Surface Mount Assembly is a leading provider of surface mount assembly and electronics manufacturing services, catering to a wide range of industries such as automotive, medical, telecommunications, and consumer electronics. With state-of-the-art facilities and a team of highly skilled professionals, the company has earned a reputation for delivering high-quality products and exceptional customer service.The company's surface mount assembly services include printed circuit board (PCB) assembly, through-hole assembly, and system integration. Their advanced surface mount technology allows for precise placement of electronic components onto the PCB, resulting in reliable and efficient electronic products. In addition to assembly services, they also offer design and engineering support to help clients optimize their products for manufacturing.In line with their commitment to quality, China Surface Mount Assembly adheres to strict quality control standards throughout the manufacturing process. They are ISO 9001 and ISO 13485 certified, ensuring that every product meets the highest industry standards. Their dedication to quality and innovation has earned them the trust of many leading companies in various industries.With a focus on technological advancement, China Surface Mount Assembly regularly invests in the latest manufacturing equipment and software to stay ahead of the competition. Their modern facilities are equipped with advanced machinery for automated assembly, inspection, and testing, allowing for high precision and efficiency in production. Additionally, they prioritize environmental sustainability and are committed to reducing waste and energy consumption in their operations.The company's experienced team of engineers and technicians are dedicated to providing comprehensive support to their clients, from initial design consultations to final product delivery. They work closely with clients to understand their specific requirements and offer tailored solutions to meet their needs. This personalized approach has helped them build strong, long-lasting relationships with their clients, who rely on them for all their manufacturing needs.China Surface Mount Assembly is dedicated to providing a seamless and efficient manufacturing experience for their clients. Their streamlined processes and proactive project management ensure on-time delivery and cost-effective solutions. Whether it's a small prototype run or a large-scale production, they have the capabilities to handle orders of any size and complexity.As the global demand for high-quality electronics continues to grow, China Surface Mount Assembly is well-positioned to meet the needs of the market. They are constantly expanding their capabilities and exploring new opportunities to provide innovative manufacturing solutions to their clients. With a strong focus on quality, efficiency, and customer satisfaction, the company is poised to remain a leader in the surface mount assembly industry.In conclusion, China Surface Mount Assembly is a trusted partner for electronic manufacturing services, offering a comprehensive range of solutions to meet the diverse needs of their clients. With a commitment to quality, innovation, and customer satisfaction, they continue to set the standard for excellence in the industry. Whether it's a new product development or ongoing production, clients can rely on China Surface Mount Assembly for reliable, high-quality manufacturing services.

Key benefits of SMT Through Hole Factories for improved manufacturing efficiency

SMT Through Hole Factories Continues to Thrive in the Electronics Manufacturing IndustryIn the fast-paced world of electronics manufacturing, SMT through hole factories have become a vital component of the supply chain, providing essential services that enable the production of high-quality electronic products for businesses and consumers alike. One such company leading the way in this industry is {}. With a proven track record of excellence and a commitment to innovation, {} has established itself as a premier provider of SMT through hole manufacturing services.{} is a leading manufacturer of electronic components and a trusted partner for businesses across a wide range of industries. The company's state-of-the-art facilities and highly skilled workforce enable it to deliver cutting-edge solutions that meet the demands of the global electronics market. {} offers a comprehensive range of services, including SMT assembly, through hole assembly, and box build assembly, providing clients with a complete manufacturing solution that meets their specific needs.At the heart of {}'s success is its dedication to quality and precision. The company's team of experts is committed to delivering superior results, and its advanced manufacturing processes and rigorous quality control measures ensure that every product meets the highest standards of excellence. With a focus on continuous improvement and the latest industry trends, {} is well-equipped to meet the evolving needs of the electronics manufacturing market.In addition to its commitment to quality, {} is also dedicated to environmental and social responsibility. The company recognizes the importance of sustainability in today's world, and it has implemented a range of initiatives to minimize its environmental impact. {}'s facilities are designed to operate efficiently and sustainably, and the company is committed to reducing waste and energy consumption throughout its manufacturing processes.In recent years, {} has seen significant growth and success in the electronics manufacturing industry, and the company shows no signs of slowing down. With a strong focus on customer satisfaction and a dedication to continuous improvement, {} is well-positioned to meet the increasing demands of the market and to continue providing exceptional SMT through hole manufacturing services to its clients.The future looks bright for the electronics manufacturing industry, and companies like {} are at the forefront of driving innovation and excellence in this fast-paced and dynamic sector. With a commitment to quality, precision, and sustainability, {} is well-prepared to continue thriving in the global market and to meet the diverse needs of its clients.As the demand for high-quality electronic products continues to grow, the role of SMT through hole factories is more important than ever, and companies like {} are playing a crucial part in delivering the cutting-edge solutions that power today's technology-driven world. With a focus on excellence and a dedication to meeting the evolving needs of the market, {} is poised to remain a key player in the electronics manufacturing industry for years to come.

Top 5 Advanced Techniques for Pcb Assembly

{Company name} is a leading provider of PCB assembly services, specializing in high-quality, reliable, and cost-effective solutions for a wide range of industries. With a strong focus on innovation and state-of-the-art technology, {company name} has established itself as a trusted partner for businesses looking to bring their electronic products to market.One of the key factors that sets {company name} apart from its competitors is its expertise in PCB assembly techniques. The process of PCB assembly is complex and requires precision and attention to detail. {company name} employs a variety of techniques to ensure that the final product meets the highest standards of quality and reliability.One of the most important PCB assembly techniques used by {company name} is surface mount technology (SMT). SMT involves mounting electronic components directly onto the surface of the PCB, as opposed to through-hole technology, which requires the components to be inserted into holes drilled in the board. SMT allows for smaller, lighter, and more efficient PCBs, and {company name} has invested in state-of-the-art SMT equipment to ensure the highest level of precision and accuracy in the assembly process.In addition to SMT, {company name} also specializes in through-hole assembly for components that require a stronger mechanical bond, as well as mixed technology assembly for products that require a combination of both SMT and through-hole components. This flexibility allows {company name} to meet the unique needs of each customer and product, providing a tailored solution that meets the highest standards of quality and reliability.Another key PCB assembly technique employed by {company name} is automated optical inspection (AOI). AOI uses advanced cameras and image recognition software to inspect the PCB for defects or irregularities, such as missing components, misaligned parts, or soldering defects. This process ensures that every PCB assembled by {company name} meets the highest standards of quality and reliability, providing customers with peace of mind and confidence in the final product.{Company name} also utilizes advanced X-ray inspection techniques to inspect the internal structure of the PCB, ensuring that all connections and components are in place and functioning properly. This level of scrutiny and attention to detail sets {company name} apart as a leader in PCB assembly, providing customers with a level of quality and reliability that is second to none.With a commitment to innovation and continuous improvement, {company name} is constantly looking for ways to enhance its PCB assembly techniques and processes. The company invests in research and development to stay at the forefront of technological advancements in the industry, ensuring that its customers have access to the latest and most advanced solutions for their electronic products.In conclusion, {company name} is a trusted and reliable partner for businesses looking for high-quality, cost-effective PCB assembly services. With a strong focus on innovation, state-of-the-art technology, and a commitment to continuous improvement, {company name} sets itself apart as a leader in the industry, providing customers with the highest standards of quality and reliability for their electronic products.

How to Build an Efficient EMS Factory: Tips for Success

Effective EMS Factories: Revolutionizing the Electronics Manufacturing IndustryIn today's fast-paced world, the demand for high-quality electronic products is constantly on the rise. From smartphones and tablets to smart home devices and wearable technology, consumers expect nothing but the best when it comes to their electronic devices. This has put a significant amount of pressure on manufacturers to deliver top-notch products in a timely manner.To meet these demands, many companies are turning to Electronic Manufacturing Services (EMS) factories to outsource their production needs. EMS factories specialize in the design, manufacturing, testing, and distribution of electronic components and products, making them an essential part of the modern electronics manufacturing industry.One company that has been at the forefront of revolutionizing the EMS industry is {}. With its state-of-the-art facilities and cutting-edge technology, {} has quickly become a trusted partner for countless companies looking to outsource their manufacturing needs.{} offers a wide range of services to meet the diverse needs of its clients. Whether it's PCB assembly, cable assembly, box build assembly, or full product assembly, {} has the capabilities and expertise to handle it all. With a strong focus on quality and precision, {} ensures that every product that comes out of its factories meets the highest standards in the industry.Furthermore, {} places a strong emphasis on efficiency and cost-effectiveness. By leveraging the latest manufacturing technologies and streamlining its processes, {} is able to deliver products on time and within budget, giving its clients a competitive edge in the market.But what truly sets {} apart from other EMS factories is its commitment to sustainability and social responsibility. With a focus on minimizing its environmental impact and promoting ethical labor practices, {} is dedicated to making a positive contribution to the communities in which it operates.In addition to its manufacturing capabilities, {} also offers a range of value-added services to support its clients every step of the way. From product design and engineering support to supply chain management and logistics, {} is a one-stop solution for all of its clients' manufacturing needs.With a proven track record of success and a strong reputation in the industry, {} has become a go-to partner for companies looking to bring their electronic products to market efficiently and effectively.As the demand for electronic products continues to grow, the role of EMS factories like {} will only become more crucial in the manufacturing landscape. By providing high-quality, cost-effective, and sustainable manufacturing solutions, {} is helping companies around the world stay ahead of the curve in an increasingly competitive industry.In conclusion, {} has established itself as a leader in the EMS industry, setting a new standard for excellence and innovation. With its state-of-the-art facilities, commitment to quality and sustainability, and comprehensive range of services, {} is well-positioned to continue revolutionizing the electronics manufacturing industry for years to come.