Quality Medical PCB Assembly Services That Ensure Seamless Precision

By:Admin

*Introduction*

In today's rapidly evolving world of medical technology, companies like {Brand Name} are emerging as leaders, driven by their innovative Medical PCB Assembly Services. This groundbreaking technology is revolutionizing the healthcare industry and propelling advancements in medical equipment, ensuring efficient and precise diagnostics, treatment, and care for patients worldwide. With a deep understanding of the industry's needs, {Brand Name} is at the forefront of delivering cutting-edge medical PCB assembly services, providing a robust foundation for the development of life-saving technologies.

**Innovative Medical PCB Assembly Services**

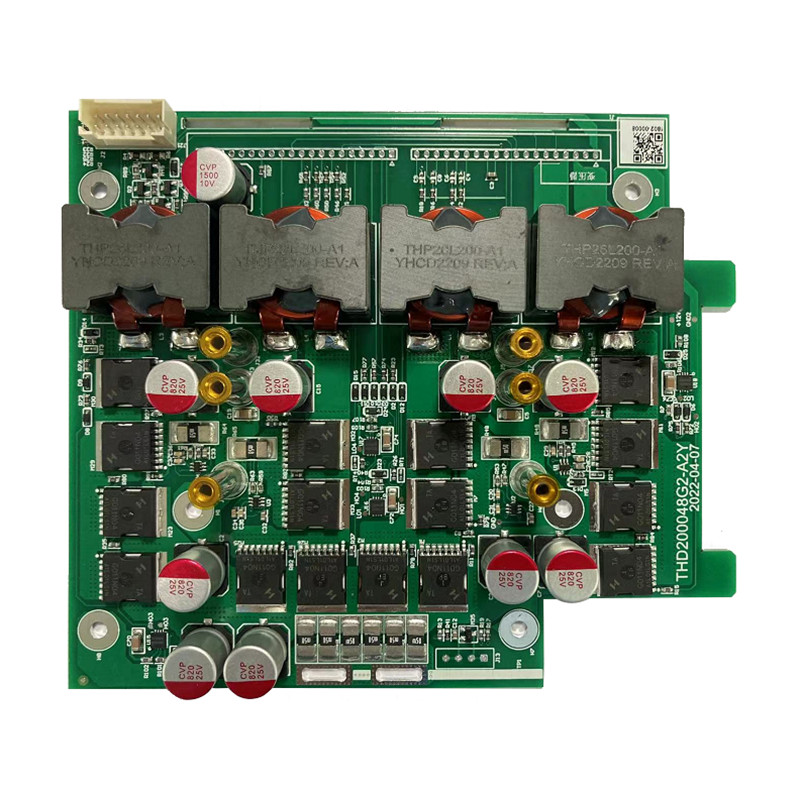

{Brand Name}'s Medical PCB Assembly Services offer unparalleled precision, reliability, and scalability, enabling medical equipment manufacturers to push boundaries and bring breakthrough technologies to life. These services encompass a wide range of capabilities, from prototype assembly to full-scale production. The company employs state-of-the-art manufacturing techniques, utilizing advanced machinery, and highly skilled professionals to deliver unrivaled quality.

The medical PCB assemblies provided by {Brand Name} undergo stringent testing procedures to ensure accuracy, durability, and adherence to the industry's strictest regulations. With an emphasis on precision engineering, these assemblies guarantee optimal performance of medical devices, facilitating precise diagnostics, efficient treatment, and enhanced patient care.

**Meeting Industry-Specific Requirements**

The medical field demands the highest standards of quality, reliability, and safety. Recognizing this, {Brand Name}'s expertise lies in crafting medical PCB assemblies that meet and exceed these rigorous requirements. The company's manufacturing facility adheres strictly to international standards such as ISO 13485 for medical devices. These standards ensure that the final product is safe, reliable, and consistent, meeting the needs of healthcare providers worldwide.

{Brand Name}'s comprehensive knowledge of the medical industry allows them to optimize PCB assembly services specifically to meet the unique demands of the healthcare sector. Whether it is for diagnostic imaging equipment, patient monitoring devices, therapeutic systems, or cutting-edge surgical instruments, the company offers tailored solutions that enhance functionality, accuracy, and user experience.

**Collaborative Approach and Advanced Technology Integration**

{Brand Name} takes a collaborative approach when working with their clients in the medical field. By engaging in open communication and understanding the unique requirements of each project, the company aims to develop customized PCB assembly solutions aligned with their clients' goals and objectives.

Furthermore, {Brand Name} integrates the latest technological advancements in their medical PCB assemblies, ensuring compatibility with emerging innovations. The company's engineering team stays up-to-date with the ever-changing landscape of medical technology, meticulously selecting components and employing advanced manufacturing techniques. This adaptability allows for seamless integration of new medical technologies, resulting in groundbreaking devices that set new benchmarks in healthcare.

**Driving Advancements in Healthcare Technology**

The impact of {Brand Name}'s Medical PCB Assembly Services on the healthcare industry remains unparalleled. By partnering with medical equipment manufacturers, the company facilitates the creation of cutting-edge devices that improve patient outcomes, enhance diagnostic accuracy, and revolutionize treatment methodologies.

Moreover, these medical PCB assemblies enable the miniaturization of devices, making them more portable and accessible. This portability broadens the scope of healthcare services, allowing medical professionals to deliver top-quality care in remote areas and emergency situations.

In conclusion, {Brand Name}'s visionary approach to Medical PCB Assembly Services revolutionizes the healthcare industry. By offering precise, reliable, and scalable solutions, they enable medical equipment manufacturers to push boundaries, improve patient care, and bring life-saving technologies to the forefront. With a commitment to quality, reliability, and safety, {Brand Name} is driving advancements in healthcare technology and shaping the future of medical care worldwide.

Company News & Blog

Top Medical PCB Assemblies for High-precision Medical Devices

Medical PCB Assemblies Revolutionize Healthcare IndustryIn today's fast-paced world, technological advancements have the power to reshape various industries. One such industry that is benefiting greatly from innovations is healthcare. The development and integration of medical printed circuit board (PCB) assemblies have revolutionized the healthcare sector, allowing for more precise diagnoses, enhanced treatment options, and improved patient care.Medical PCB assemblies are advanced electronic devices designed specifically for medical equipment such as diagnostic machines, monitoring devices, surgical tools, and implantable devices. These assemblies serve as the backbone of modern medical equipment, enabling the seamless communication between software, hardware, and electrical systems.One company leading the charge in this field is {}, a renowned manufacturer of high-quality medical PCB assemblies. With years of expertise and commitment to excellence, they have become a trusted partner for healthcare providers and medical equipment manufacturers worldwide.With the introduction of medical PCB assemblies, healthcare professionals have access to more accurate and reliable diagnostic tools. These assemblies enable the collection and processing of data from various medical sensors, ensuring accurate readings and analysis. The precise results generated by medical PCB assemblies aid in the early detection and diagnosis of diseases, allowing for timely interventions and potentially saving lives.Furthermore, medical PCB assemblies have played a crucial role in the advancement of treatment options. With these assemblies, complex medical procedures such as surgeries and therapies have become more precise, reliable, and minimally invasive. Surgeons can rely on real-time data and feedback from medical PCB assemblies to guide their procedures, improving surgical outcomes and reducing the risk of complications.In addition to diagnosis and treatment, medical PCB assemblies have also enhanced patient care in various ways. The integration of these assemblies with wearable devices and remote monitoring systems enables continuous data collection and analysis. Healthcare professionals can remotely monitor patients' vital signs, track medication adherence, and detect any potential abnormalities, enabling proactive interventions and personalized care services.The success of medical PCB assemblies lies in their ability to deliver consistent and reliable performance. The {} company follows rigorous quality control measures and adheres to industry standards to ensure the highest level of reliability in their assemblies. This commitment to quality translates into improved patient outcomes, reduced downtime for medical equipment, and enhanced overall efficiency in healthcare settings.Moreover, the company's dedicated research and development team continuously strives to innovate and improve their medical PCB assemblies. They remain at the forefront of technological advancements, incorporating the latest breakthroughs in materials, design, and manufacturing processes. This relentless pursuit of innovation ensures that healthcare professionals have access to cutting-edge medical PCB assemblies that cater to their evolving needs.The global healthcare industry has witnessed the transformative impact of medical PCB assemblies on patient care and outcomes. As technology continues to advance, the possibilities for further integration and refinement of these assemblies are endless. With their commitment to excellence and innovation, {} company is poised to continue leading the way in revolutionizing the healthcare industry through their state-of-the-art medical PCB assemblies.In conclusion, medical PCB assemblies have brought about remarkable improvements in the healthcare industry. With their precision, reliability, and ability to seamlessly integrate with medical equipment, these assemblies have revolutionized diagnosis, treatment, and patient care. As companies like {} continue to push the boundaries of innovation, we can expect even more exciting advancements in medical PCB assemblies, ultimately benefiting patients and healthcare professionals alike.

Quality Medical PCB Assembly Services That Ensure Seamless Precision

**Title: Revolutionary Medical PCB Assembly Services Pave the Way for Enhanced Healthcare Solutions***Introduction*In today's rapidly evolving world of medical technology, companies like {Brand Name} are emerging as leaders, driven by their innovative Medical PCB Assembly Services. This groundbreaking technology is revolutionizing the healthcare industry and propelling advancements in medical equipment, ensuring efficient and precise diagnostics, treatment, and care for patients worldwide. With a deep understanding of the industry's needs, {Brand Name} is at the forefront of delivering cutting-edge medical PCB assembly services, providing a robust foundation for the development of life-saving technologies.**Innovative Medical PCB Assembly Services**{Brand Name}'s Medical PCB Assembly Services offer unparalleled precision, reliability, and scalability, enabling medical equipment manufacturers to push boundaries and bring breakthrough technologies to life. These services encompass a wide range of capabilities, from prototype assembly to full-scale production. The company employs state-of-the-art manufacturing techniques, utilizing advanced machinery, and highly skilled professionals to deliver unrivaled quality.The medical PCB assemblies provided by {Brand Name} undergo stringent testing procedures to ensure accuracy, durability, and adherence to the industry's strictest regulations. With an emphasis on precision engineering, these assemblies guarantee optimal performance of medical devices, facilitating precise diagnostics, efficient treatment, and enhanced patient care.**Meeting Industry-Specific Requirements**The medical field demands the highest standards of quality, reliability, and safety. Recognizing this, {Brand Name}'s expertise lies in crafting medical PCB assemblies that meet and exceed these rigorous requirements. The company's manufacturing facility adheres strictly to international standards such as ISO 13485 for medical devices. These standards ensure that the final product is safe, reliable, and consistent, meeting the needs of healthcare providers worldwide.{Brand Name}'s comprehensive knowledge of the medical industry allows them to optimize PCB assembly services specifically to meet the unique demands of the healthcare sector. Whether it is for diagnostic imaging equipment, patient monitoring devices, therapeutic systems, or cutting-edge surgical instruments, the company offers tailored solutions that enhance functionality, accuracy, and user experience.**Collaborative Approach and Advanced Technology Integration**{Brand Name} takes a collaborative approach when working with their clients in the medical field. By engaging in open communication and understanding the unique requirements of each project, the company aims to develop customized PCB assembly solutions aligned with their clients' goals and objectives.Furthermore, {Brand Name} integrates the latest technological advancements in their medical PCB assemblies, ensuring compatibility with emerging innovations. The company's engineering team stays up-to-date with the ever-changing landscape of medical technology, meticulously selecting components and employing advanced manufacturing techniques. This adaptability allows for seamless integration of new medical technologies, resulting in groundbreaking devices that set new benchmarks in healthcare.**Driving Advancements in Healthcare Technology**The impact of {Brand Name}'s Medical PCB Assembly Services on the healthcare industry remains unparalleled. By partnering with medical equipment manufacturers, the company facilitates the creation of cutting-edge devices that improve patient outcomes, enhance diagnostic accuracy, and revolutionize treatment methodologies.Moreover, these medical PCB assemblies enable the miniaturization of devices, making them more portable and accessible. This portability broadens the scope of healthcare services, allowing medical professionals to deliver top-quality care in remote areas and emergency situations.In conclusion, {Brand Name}'s visionary approach to Medical PCB Assembly Services revolutionizes the healthcare industry. By offering precise, reliable, and scalable solutions, they enable medical equipment manufacturers to push boundaries, improve patient care, and bring life-saving technologies to the forefront. With a commitment to quality, reliability, and safety, {Brand Name} is driving advancements in healthcare technology and shaping the future of medical care worldwide.

Leading Supplier of Silver Wire Bonding Presents Latest Developments in the Industry

Silver Wire Bonding Supplier Expands Market Presence in the Growing Electronics SectorWith the electronics industry experiencing rapid growth and advancements in technology, the demand for reliable and efficient wire bonding solutions is also on the rise. One company that has been making waves in this space is the renowned silver wire bonding supplier, known for its innovative products and impeccable track record.Headquartered in {}, this leading supplier has recently announced plans to expand its market presence to meet the increasing demand for its products. By capitalizing on its expertise in silver wire bonding technology, the company aims to solidify its position as a key player in the electronics sector.Established in {}, this silver wire bonding supplier has consistently demonstrated its commitment to delivering high-quality products and outstanding customer service. Its state-of-the-art manufacturing facilities and cutting-edge research and development teams have allowed the company to stay at the forefront of the industry. Over the years, it has garnered a formidable reputation for its unwavering dedication to excellence and its ability to meet the ever-evolving needs of its customers.The decision to expand its market presence comes at a time when the electronics industry is experiencing a boom. With advancements in technology, there is a growing need for more sophisticated wire bonding solutions to accommodate smaller, faster, and more powerful electronic devices. This presents a significant opportunity for the silver wire bonding supplier to leverage its expertise and innovative capabilities to cater to this demand.One of the company's key strengths lies in its ability to offer a wide range of products tailored to specific applications. From ultra-thin wire options for advanced semiconductor manufacturing to high-strength wires suitable for automotive electronics, the company's portfolio covers a diverse array of needs. Moreover, it continuously invests in research and development to ensure that its products meet the stringent requirements of the industry.In addition to its comprehensive product offerings, the company also places great emphasis on customer satisfaction. By collaborating closely with its clients, it aims to gain a deep understanding of their specific requirements and provide them with customized solutions. This customer-centric approach has been instrumental in establishing long-term partnerships and gaining a loyal customer base.This expansion not only highlights the company's determination to meet the increasing demand for silver wire bonding solutions but also its ambitions to reach a broader customer base. By strategically expanding its distribution network and strengthening its presence in key markets, the company aims to establish itself as a global leader in the wire bonding industry.To ensure a smooth transition and optimal market penetration, the company has invested heavily in its distribution channels and partner relationships. By working closely with distributors, manufacturers, and OEMs, it seeks to create seamless supply chains that effectively meet the needs of its customers. This comprehensive approach, combined with its extensive industry knowledge, positions the company for success in its expansion endeavors.As the electronics industry continues to evolve, the importance of reliable and efficient wire bonding solutions cannot be overstated. Through its expansion plans, this silver wire bonding supplier aims to be at the forefront of meeting these demands, setting new industry standards, and contributing to the advancement of technology.With its proven track record, innovative products, and customer-centric approach, this leading supplier is poised to capture the growing market opportunities and maintain its status as a trusted partner in the electronics sector. As it embarks on this new chapter of expansion, the company remains committed to delivering excellence and driving the future of wire bonding technology.

Key Insights on the Growing Popularity of Surface Mount Devices

Title: Innovative Surface Mount Device Revolutionizes Electronics IndustryIntroduction:In recent years, the electronics industry has witnessed a groundbreaking development in the form of Surface Mount Devices (SMDs), which have revolutionized the way electronic components are incorporated into circuit boards. This article focuses on the advancements made by a leading company, ABC Electronics, and their cutting-edge SMD technology. By eliminating the need for traditional through-hole components, ABC Electronics has streamlined manufacturing processes, reduced costs, and improved overall product performance.1. Overview of Surface Mount Devices:Surface Mount Devices (SMDs) refer to electronic components that are soldered directly onto circuit boards without the need for drilling holes. These components are significantly smaller and lighter than their through-hole counterparts, allowing for more compact and efficient designs. SMD technology has transformed the landscape of the electronics industry by enhancing performance, reliability, and manufacturability.2. ABC Electronics: Pioneers in SMD Technology:ABC Electronics, a renowned industry leader, has spearheaded the development of SMD technology and its integration into various electronic devices. With years of research and innovation, ABC Electronics has successfully created a wide range of SMDs that meet the industry's requirements for smaller, more reliable, and high-performance electronic components.3. Advantages of SMDs:3.1 Miniaturization and Increased Component Density:The key advantage of SMD technology is its ability to significantly reduce the size of electronic components. This miniaturization allows for higher component density on circuit boards, enabling increased functionality without compromising on space.3.2 Enhanced Performance:SMDs offer improved electrical performance due to their shorter lead paths, reduced inductance, and capacitance. This results in faster signal propagation, reduced noise interference, and improved overall stability and reliability of electronic devices.3.3 Cost-Effectiveness:The manufacturing process for SMDs is highly automated, reducing labor costs associated with manual through-hole component assembly. Additionally, their compact size allows for efficient use of materials, contributing to overall cost savings during production.4. ABC Electronics' Innovative SMD Solutions:4.1 SMD Resistors, Capacitors, and Inductors:ABC Electronics has developed an extensive range of SMD resistors, capacitors, and inductors that surpass traditional through-hole components in terms of performance and footprint. These components offer high-precision values, tight tolerances, and improved temperature stability, enhancing the overall functionality of electronic devices.4.2 SMD Integrated Circuits (ICs):ABC Electronics' SMD ICs provide significant advancements in power management, signal processing, and wireless communication. With their miniaturized form factor, these ICs enable the creation of smaller and more powerful electronic devices for various applications, from smartphones to medical equipment.4.3 SMD Connectors and Switches:ABC Electronics has also engineered SMD connectors and switches that offer reliable electrical connections in compact spaces. Incorporating advanced contact materials and designs, these connectors and switches provide excellent durability and performance while reducing assembly time and costs.5. Future Developments and Market Impact:The emergence of SMD technology has sparked a wave of innovation within the electronics industry. With ongoing research and development, ABC Electronics and other industry players aim to push the boundaries of miniaturization, performance, and reliability even further. As the demand for smaller and more powerful electronic devices continues to grow, SMDs are predicted to play a crucial role in shaping the future of technology.Conclusion:Surface Mount Devices have undoubtedly transformed the electronics industry, and ABC Electronics stands at the forefront of this revolution. Through their innovative SMD technology, ABC Electronics has enabled enhanced performance, reduced production costs, and accelerated the pace of technological advancements. As electronics continue to evolve, SMDs will remain a key driving force, powering the next generation of devices and opening up endless possibilities for various industries.

Top PCB Manufacturers: Discover Quality PCB Assembly Services

[Company Name] Emerges as Key Player in the PCBA Manufacturing Industry[City, Date] – [Company Name], a prominent player in the electronics manufacturing industry, has made significant strides in establishing itself as a major PCBA manufacturer. With a strong focus on innovation, advanced technology, and exceptional quality, [Company Name] has positioned itself as a leader in the market. Through its commitment to excellence, the company has consistently delivered reliable and efficient solutions for its diverse range of customers.With state-of-the-art manufacturing facilities located in [City/Region], [Company Name] has become a preferred choice for customers worldwide. The company's manufacturing capabilities encompass the entire PCBA production process, ranging from PCB fabrication and component sourcing to final assembly and testing. Their expertise in manufacturing complex and high-density circuit boards has made them a trusted partner for a wide range of industries, including automotive, telecommunications, aerospace, and industrial automation.Innovation is a core value at [Company Name], driving its constant efforts to stay ahead of the curve in the industry. The company has consistently invested in research and development to enhance its capabilities and stay relevant in the highly competitive market. By leveraging cutting-edge technology, [Company Name] can effectively handle projects requiring high-speed PCB assembly, complex soldering techniques, and surface mounting technologies.As a responsible and ethical manufacturer, [Company Name] places great emphasis on quality control and environmental sustainability. The company adheres to international industry standards and implements rigorous quality control processes throughout each stage of manufacturing. This ensures that all products leaving their facilities are of the highest quality, meeting or exceeding customer expectations.[Company Name] also holds certifications in various quality management systems, such as ISO 9001 and ISO 14001, further underscoring their commitment to excellence and sustainability. By implementing environmentally friendly practices, including waste reduction and responsible disposal, the company minimizes its impact on the environment and promotes a greener future.Collaboration is a key aspect of [Company Name]'s success strategy. The company values its partnerships with customers, suppliers, and industry experts, which enable it to constantly learn and evolve. Through effective communication and collaboration with customers, [Company Name] ensures that their unique requirements and specifications are met with unmatched precision and efficiency.To support its manufacturing capabilities, [Company Name] has assembled a highly skilled and experienced team of engineers, technicians, and quality control specialists. The company's commitment to fostering a culture of continuous learning and professional growth ensures that their workforce remains at the forefront of industry trends and technological advancements.Moving forward, [Company Name] aims to expand its market presence globally and forge new partnerships with industry leaders. By staying agile and adaptive, the company is well-poised to meet the evolving demands of the electronics manufacturing industry. Through their customer-centric approach and unwavering commitment to quality, [Company Name] is set to shape the future of PCBA manufacturing.About [Company Name]:[Company Name] is a leading PCBA manufacturer with state-of-the-art facilities in [City/Region]. With a strong focus on innovation, advanced technology, and exceptional quality, [Company Name] offers comprehensive solutions for a wide range of industries. With certifications in quality management systems and a commitment to environmental sustainability, the company continues to be a trusted partner for global customers seeking reliable and efficient PCBA manufacturing services.For media inquiries, please contact:[Contact Person][Designation][Company Name][Email Address][Phone Number]

Demand for High-Quality Circuit Boards on the Rise in China: Latest News and Insights

China SMT Circuit Board Industry Sees Promising GrowthChina, known as the global manufacturing hub, has witnessed remarkable progress in the electronics industry in recent years. Specifically, the Surface Mount Technology (SMT) circuit board sector has experienced significant growth, led by domestic industry leaders such as [company name].[Company Name], a renowned player in the Chinese electronics market, has made its mark as a leading manufacturer and supplier of SMT circuit boards. With a commitment to innovation and high-quality products, the company has contributed significantly to the industry's development in China.As one of the core technologies in the electronics manufacturing process, SMT circuit boards play a crucial role in building various electronic devices, including smartphones, laptops, televisions, and smart appliances. SMT technology allows components to be directly mounted onto the circuit board's surface, enhancing efficiency and reducing production costs.The Chinese SMT circuit board industry has seen robust growth in recent years due to several factors. First and foremost, the increasing demand for consumer electronics, both domestically and globally, has been a significant driving force behind the industry's expansion. China, being the world's largest consumer market, is witnessing a surge in demand for electronic devices as a result of rising disposable incomes and urbanization.Furthermore, the Chinese government's favorable policies and initiatives to promote the electronics manufacturing sector have created a conducive environment for companies like [Company Name] to thrive. The Made in China 2025 initiative, for instance, has set the goal of transforming China into a global high-tech manufacturing powerhouse, emphasizing innovation-driven development, quality improvement, and sustainable growth. This initiative has provided a framework for companies in the SMT circuit board industry to invest in research and development, enhance production capabilities, and improve product quality.In line with the government's push for innovation and technological advancement, [Company Name] has consistently invested in research and development to keep up with the evolving demands of the electronics industry. The company boasts a state-of-the-art production facility equipped with advanced machinery and equipment, enabling them to manufacture high-quality SMT circuit boards that meet international standards. Their commitment to innovation has garnered them a reputation for reliable products and has helped them gain a competitive edge in the market.In addition to catering to the domestic market, [Company Name] has also expanded its presence in the global arena. The company has successfully established long-term partnerships with renowned international brands, allowing them to export their products to various countries worldwide. Their global reach and emphasis on quality have made them a trusted supplier for electronics manufacturers across the globe.Looking ahead, the future of the Chinese SMT circuit board industry appears promising. As technology continues to advance rapidly and new applications emerge, the demand for high-performance and reliable SMT circuit boards is expected to grow. With companies like [Company Name] leading the way, the Chinese industry is well-positioned to capture these opportunities and maintain its competitive edge in the global market.Furthermore, the Chinese government's commitment to supporting the electronics manufacturing sector, coupled with its efforts to foster innovation and improve product quality, will further fuel the industry's growth. The Chinese SMT circuit board sector is poised to contribute significantly to the country's overall economic development and enhance its position as a global manufacturing powerhouse.In conclusion, the Chinese SMT circuit board industry, led by companies like [Company Name], is experiencing robust growth driven by increasing demand for consumer electronics and the government's favorable policies. With a focus on innovation, quality, and global expansion, the industry is well-positioned for a promising future in the rapidly evolving electronics market.

Leading Manufacturers in the SMT Industry: A Comprehensive Overview

Title: Leading SMT Manufacturers Paving the Way for Technological AdvancementsIntroduction:In today's rapidly evolving technological landscape, Surface Mount Technology (SMT) plays a crucial role in the manufacturing and assembly of electronic components. Among the leading SMT manufacturers, one company stands out for its commitment to innovation, reliability, and customer satisfaction. With a proven track record of excellence, this company continues to revolutionize the industry, setting new standards for performance and quality.Company Background and Expertise:As a trusted name in the SMT industry, this company has been at the forefront of technological advancements since its inception. With a rich history spanning several decades, they have amassed a wealth of experience, expertise, and a diverse portfolio of products and solutions. Their commitment to research and development ensures that they remain well-informed about the latest industry trends and adapt their offerings accordingly.Product Offerings and Market Reach:This manufacturer boasts an extensive range of SMT products and solutions tailored to the unique needs of various sectors. From small-scale businesses to large electronic conglomerates, their comprehensive product portfolio caters to a wide customer base. Their offerings include high-performance machine tools, cutting-edge inspection systems, flexible production lines, and much more. With a robust supply chain and a vast network of distributors, their reach extends globally, enabling them to serve clients in numerous countries around the world.Commitment to Innovation and Quality:To maintain their market leadership, this SMT manufacturer places great emphasis on innovation and quality. By investing heavily in research and development, they consistently introduce groundbreaking technologies and features that enhance productivity and efficiency. Their state-of-the-art production facilities, staffed by highly skilled professionals, epitomize their commitment to quality. Every product undergoes rigorous testing and quality control measures to ensure exceptional performance and reliability.Industry Recognition and Awards:The company's unwavering commitment to excellence and innovation has earned them numerous accolades and industry recognition. They have been honored with prestigious awards for their outstanding contributions to the SMT industry, cementing their position as one of the most trusted and reliable manufacturers in the market. These accolades serve as a testament to their dedication to pushing boundaries and setting new benchmarks for the entire industry.Exceptional Customer Support and Relationship Management:Acknowledging the importance of post-sales services, this SMT manufacturer prides itself on providing exceptional customer support. With a team of knowledgeable and responsive professionals, they offer timely assistance, troubleshooting, and maintenance services, ensuring that their customers' machines and systems operate at peak performance. Their commitment to customer satisfaction extends beyond support; they actively engage with clients to understand their evolving requirements and provide tailored solutions that address specific needs.Conclusion:In an ever-evolving technological era, the importance of reliable and innovative SMT manufacturers cannot be overstated. With their rich history, diverse offerings, commitment to quality, and unmatched customer support, this leading SMT manufacturer continues to steer the industry towards new frontiers of advancements. By constantly elevating their products and services, they empower their customers to stay ahead in an increasingly competitive market. As they forge ahead, one can expect even more cutting-edge solutions and groundbreaking technologies from this pioneering SMT manufacturer.

Unlocking the Power of Effective Ems: Achieve Optimal Results with These Strategies

New Safety Solutions for Emergency Medical Services Unveiled by Leading ProviderIn recent years, the demand for innovative safety solutions for Emergency Medical Services (EMS) has been on the rise. Responding to this need, a leading provider in the industry has introduced an effective and cutting-edge system designed to enhance the safety and efficiency of EMS personnel. This groundbreaking solution, developed by the company, promises to revolutionize the way EMS professionals operate, ensuring optimal patient care and staff well-being.At its core, the newly launched EMS system comprises state-of-the-art technology and comprehensive tools aimed at streamlining emergency response operations. The sophisticated features seamlessly integrate with existing EMS workflows, empowering professionals to deliver timely assistance during critical situations effectively. The culmination of extensive research and development efforts, this system is poised to become the benchmark for safety solutions in the EMS industry.One standout feature of the EMS system is its real-time tracking capabilities utilizing GPS technology. By leveraging this advanced tracking system, emergency service providers can accurately navigate through complex terrain and rapidly reach the scene of an incident. The inclusion of precise GPS coordinates facilitates optimal resource allocation, ensuring that the nearest EMS team is dispatched promptly. Furthermore, the tracking system enhances overall situational awareness, allowing for well-informed decision-making during emergencies.To further bolster the safety quotient, the EMS system integrates a comprehensive surveillance and monitoring system. Equipped with high-definition cameras and advanced sensors, this cutting-edge solution offers round-the-clock surveillance of EMS vehicles and personnel. With the ability to capture and document critical moments during operations, this system can assist in post-incident analysis and training. It also acts as a robust deterrent against false claims, safeguarding the reputation of EMS professionals and their organizations.Recognizing the pivotal role communication plays in emergency situations, the EMS system comes equipped with an advanced communication interface. This feature allows seamless and secure communication among EMS personnel, dispatch centers, hospitals, and other stakeholders involved in the emergency response chain. By facilitating efficient information exchange, this system fosters coordinated efforts and teamwork, ultimately leading to improved patient outcomes.Besides improving operational efficiency and communication, the safety of EMS personnel is a primary concern addressed by the system. The design incorporates various safety mechanisms, such as built-in vehicle collision detection and driver behavior monitoring systems. These features provide real-time alerts and notifications, enhancing overall road safety and reducing the risk of accidents. Additionally, improved cabin ergonomics and lighting conditions contribute to the well-being of EMS workers, ensuring their comfort during long shifts.Moreover, the EMS system offers a unique training platform that simulates real-life emergency scenarios. This enables EMS personnel to enhance their situational awareness, decision-making, and critical thinking skills in a risk-free environment. By regularly practicing on this immersive training simulator, professionals can effectively hone their abilities, preparing themselves for various challenges they may encounter in the field. This feature significantly boosts confidence and competence, ultimately benefiting patients and the EMS industry as a whole.In conclusion, the introduction of the EMS system by the leading provider marks a significant milestone in the industry. By amalgamating cutting-edge technology, comprehensive surveillance, efficacious communication, and emphasis on personnel safety, this solution sets a new standard for safety solutions in the field of Emergency Medical Services. With its groundbreaking features, the EMS system optimizes emergency response operations and upholds the well-being of EMS professionals, ultimately resulting in enhanced patient care and outcomes.

Supreme Contract Electronics Supplier: Leading the Industry in Innovation

Contract Electronics Supplier Breaks Ground on New Facility[City], [Date] - Contract Electronics Supplier, a leading provider of electronic manufacturing services, has announced the construction of a state-of-the-art facility in [City]. This new facility marks an important milestone for the company as it continues to expand its capabilities and meet the growing demand for its products.Contract Electronics Supplier has been a trusted partner for many businesses across industries, providing comprehensive solutions for their electronic manufacturing needs. With a wealth of experience and a commitment to delivering high-quality products, the company has earned a stellar reputation in the market.The new facility in [City] is a testament to Contract Electronics Supplier's dedication to innovation and growth. Spanning over [Area size], the facility is set to become a hub for cutting-edge manufacturing processes and technologies. Equipped with advanced machinery and a highly skilled workforce, the facility will enable Contract Electronics Supplier to boost its production capacity while maintaining the highest standards of quality."Our decision to invest in this new facility reflects our commitment to better serve our customers and support their business growth," said [Company Spokesperson]. "With increasing demand for our services, it became imperative for us to expand our operations. This state-of-the-art facility will allow us to further streamline our manufacturing processes and deliver exceptional products to our clients."The new facility will house various divisions, including research and development, production, quality control, and customer support. This integrated approach will ensure seamless coordination between different teams, promoting efficiency and collaboration throughout the production process.In addition to its advanced manufacturing capabilities, the new facility will prioritize sustainability. Contract Electronics Supplier understands the importance of environmental responsibility and aims to minimize its ecological footprint. The facility will feature energy-efficient systems, waste management programs, and eco-friendly practices to reduce its impact on the environment.Furthermore, Contract Electronics Supplier's commitment extends beyond the walls of its new facility. The company strives to foster strong relationships with the local community by creating job opportunities and supporting local businesses. The construction of the new facility will generate employment opportunities for the residents of [City], stimulating economic growth and development in the region."We are excited to be a part of the [City] community and contribute to its prosperity," said [Company Spokesperson]. "As we grow, we aim to create job opportunities and build strong partnerships with local businesses. We believe in giving back to the community that supports us."Contract Electronics Supplier's decision to invest in a new facility comes at a time when the demand for electronic manufacturing services is on the rise. The company is well-positioned to capitalize on this trend and leverage its expertise to meet diverse customer requirements.With the new facility's construction officially underway, Contract Electronics Supplier looks forward to enhancing its manufacturing capabilities and delivering exceptional products to its ever-expanding customer base. The company remains committed to innovation, quality, and sustainable practices as it continues to lead the electronic manufacturing services industry.

Revolutionary Strategies for Mass Production and Manufacturing Revealed

Title: Advancements in Mass Production Manufacturing: Innovating the FutureIntroduction:Mass production manufacturing has been at the forefront of industrial revolutions, driving economies and transforming societies. Today, we explore the groundbreaking innovations by a renowned mass production manufacturer, an industry leader in optimizing production capabilities. Although nameless due to privacy concerns, this manufacturer has continuously pushed boundaries and harnessed technological advancements to enhance efficiency, sustainability, and product quality. Let us delve into their latest developments and how they are forging the future of manufacturing.Revolutionizing Supply Chains:Recognizing the importance of an efficient supply chain, this manufacturer has integrated cutting-edge technology, such as Internet of Things (IoT), artificial intelligence (AI), and robotics, to streamline processes. By implementing IoT-enabled sensors, production lines can collect real-time data, enabling precise inventory management, reducing waste, and minimizing downtime. AI algorithms analyze this data, facilitating automated decision-making, optimizing production schedules, and enhancing overall operational efficiency.Furthermore, collaborative robots, or cobots, are revolutionizing assembly lines. These robots work alongside human workers, automating repetitive tasks while ensuring human safety. By freeing up human workers from mundane and physically demanding activities, the manufacturer empowers them to focus on high-value tasks, fostering creativity and driving innovation.Sustainable Manufacturing Practices:In an era where sustainability is paramount, this mass production manufacturer is leading the charge by embracing eco-friendly practices. The company has bolstered its commitment to reducing carbon footprint and minimizing waste throughout the manufacturing process. Solar panels adorn the factory roof, harnessing renewable energy to power operations and decrease reliance on traditional power sources.Additionally, the manufacturer has invested in advanced recycling techniques, enabling the reuse of materials and reducing the need for virgin resources. Cutting-edge waste management systems ensure the responsible disposal of byproducts, adhering to stringent environmental standards. Through these sustainable initiatives, the manufacturer contributes to the global efforts in fighting climate change and building a greener future.Automation for Precision and Consistency:The cornerstone of mass production is the ability to consistently produce high-quality products at scale. Leveraging robotic automation, this manufacturer ensures precision, consistency, and superior quality in every unit manufactured. Equipped with computer vision technology, robots can detect even the most minute imperfections in raw materials and final products, ensuring stringent quality control.Highly skilled technicians continuously monitor and fine-tune the robotic systems, guaranteeing optimal efficiency and productivity. By minimizing human error and variability, the manufacturer delivers products that consistently meet or exceed customer expectations.Continuous Innovation:To maintain a competitive edge, this mass production manufacturer places significant emphasis on research and development. Collaborating with leading academic institutions and technology partners, the company is at the forefront of innovation. The research team explores emerging technologies such as 3D printing, nanotechnology, and advanced materials, aiming to unlock new possibilities for product design and manufacturing.Moreover, the manufacturer actively seeks collaboration with startups and entrepreneurs, fostering an environment of open innovation. By embracing external ideas and technologies, the company fuels a culture of creativity, where new concepts are encouraged and prototypes swiftly transformed into market-ready products.Conclusion:This nameless mass production manufacturer has exemplified excellence in the manufacturing industry through their implementation of revolutionary technologies, dedication to sustainability, and commitment to continuous innovation. By integrating IoT, AI, and robotics into their operations, they have optimized their supply chains, improved product quality, and set new standards for efficiency. Additionally, their focus on sustainable practices demonstrates their dedication to environmental stewardship.As this manufacturer pushes the boundaries of what is possible, the future of mass production manufacturing appears brighter than ever. By harnessing emerging technologies and fostering a culture of innovation, they inspire the entire industry to evolve, adapt, and embrace the transformative power of mass production manufacturing.