Reliable Soldering Machine Supplier for all your Industrial needs

By:Admin

The company's mission is to provide reliable and efficient equipment that meets the ever-evolving demands of the electronic manufacturing industry. By leveraging their expertise and in-depth knowledge of the market, Smt Soldering Machine Supplier has been able to develop a comprehensive product line that caters to a wide range of applications and production needs.

One of the key factors that sets Smt Soldering Machine Supplier apart from their competitors is their dedication to research and development. The company invests heavily in exploring new technologies and methodologies to improve their products and services. This commitment to innovation has enabled Smt Soldering Machine Supplier to stay ahead of the curve and offer cutting-edge solutions to their customers.

In addition to their focus on innovation, Smt Soldering Machine Supplier also places a high emphasis on quality control. Each product undergoes rigorous testing and inspection to ensure that it meets the highest standards of reliability and performance. By adhering to strict quality control measures, the company is able to deliver products that consistently exceed customer expectations.

Furthermore, Smt Soldering Machine Supplier has a strong customer-centric approach, prioritizing the needs and requirements of their clients. The company works closely with customers to understand their specific challenges and goals, and then provides customized solutions that address these unique needs. This level of personalized attention has earned Smt Soldering Machine Supplier a reputation for exceptional customer service and support.

With a growing global footprint, Smt Soldering Machine Supplier has established partnerships and connections with distributors and manufacturers worldwide. This extensive network allows the company to reach customers in different regions and provide them with prompt and efficient service. By leveraging their business relationships, Smt Soldering Machine Supplier has been able to expand their reach and become a leading supplier in the electronic manufacturing industry.

Looking to the future, Smt Soldering Machine Supplier remains committed to driving innovation and delivering superior products and services to their customers. The company is constantly exploring new opportunities for growth and expansion, and is dedicated to staying at the forefront of the industry. Through their ongoing efforts, Smt Soldering Machine Supplier aims to continue setting new standards for quality and performance in the electronic manufacturing sector.

In conclusion, Smt Soldering Machine Supplier has solidified its position as a trusted provider of soldering machines and related equipment. With a strong focus on innovation, quality control, and customer satisfaction, the company has earned a reputation for excellence in the industry. As they continue to expand their global reach and pursue new opportunities, Smt Soldering Machine Supplier is poised to lead the way in electronic manufacturing for years to come.

Company News & Blog

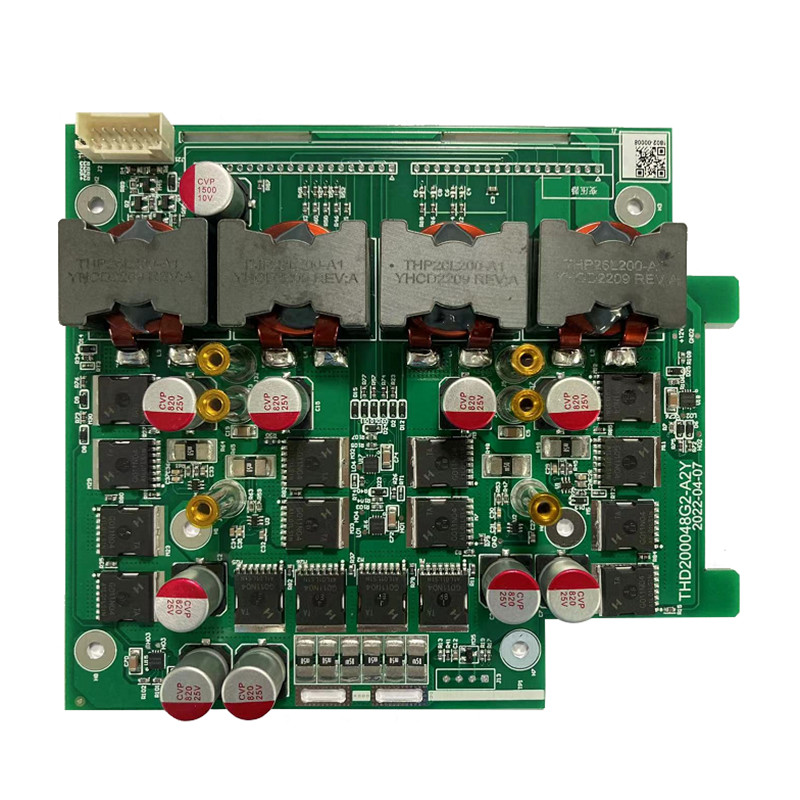

High-Quality Printed Board Assembly Services for Electronics Manufacturing

Printed Board Assembly (PBA) is a crucial component in the manufacturing of electronic devices. PBA involves the assembly of various electronic components onto a printed circuit board (PCB) to create a functional electronic device or system. This process requires precision, expertise, and advanced machinery to ensure the reliability and functionality of the final product.The process of Printed Board Assembly begins with the procurement of components, such as resistors, capacitors, integrated circuits, and connectors. These components are then carefully placed onto the PCB using advanced pick-and-place machines. Once the components are placed, the PCB is passed through a reflow soldering process, where the components are permanently attached to the board. After soldering, the PCB undergoes rigorous testing to ensure the functionality and reliability of the assembled board.One company that excels in the field of Printed Board Assembly is {}. They specialize in providing high-quality PBA services for a wide range of electronic devices, including consumer electronics, automotive electronics, medical devices, and industrial equipment. With their state-of-the-art manufacturing facility and a team of experienced engineers, they are able to deliver top-notch Printed Board Assembly services that meet the highest industry standards.{} takes pride in their ability to handle complex assemblies and tight production schedules. Their team of engineers works closely with clients to understand their specific requirements and provide customized PBA solutions that meet their unique needs. With a focus on quality, reliability, and efficiency, {} ensures that every Printed Board Assembly project is completed to the highest standard.In addition to their expertise in Printed Board Assembly, {} also offers a wide range of services, including PCB design, prototyping, and electronic testing. Their comprehensive approach to electronic manufacturing allows them to support clients at every stage of the product development process, from initial concept to final production.One of the key factors that sets {} apart from other PBA service providers is their commitment to quality and continuous improvement. They adhere to strict quality control processes and standards to ensure that every assembled board meets the highest quality and reliability requirements. Moreover, they invest in the latest manufacturing technologies and equipment to stay ahead of industry trends and deliver cutting-edge PBA solutions.As the demand for electronic devices continues to grow, the importance of reliable Printed Board Assembly services cannot be overstated. Companies like {} play a critical role in enabling the production of high-quality electronic devices that power our modern world. With their expertise, advanced capabilities, and commitment to excellence, {} is well-positioned to meet the evolving needs of the electronics industry and contribute to the development of innovative electronic products.In conclusion, Printed Board Assembly is a vital process in the manufacturing of electronic devices, and companies like {} are at the forefront of providing high-quality PBA services. With their expertise, advanced capabilities, and commitment to quality, {} is well-equipped to meet the diverse needs of clients across various industries. As the demand for electronic devices continues to rise, the role of Printed Board Assembly in enabling the production of reliable electronic products cannot be understated. Companies like {} are instrumental in driving the innovation and advancement of electronic manufacturing.

Pca Printed Circuit Assembly: Unveiling the Latest Advances in Circuit Board Technology

Title: Printed Circuit Assembly (PCA) Industry Witnesses Strong Growth Amid Technological AdvancementsIntroduction:In recent years, the Printed Circuit Assembly (PCA) industry has experienced a remarkable surge in growth, driven by rapid technological advancements and the increasing demand for electronic devices across various sectors. PCA, a critical component of modern electronic systems, has become a vital manufacturing process that enables the production of complex electronic circuits. This article will delve into the thriving PCA industry and its significant contributions to technological innovation.The Rise of Printed Circuit Assembly (PCA):Printed Circuit Assembly is an integral part of the electronics manufacturing industry, facilitating the production of electronic components and devices. Through a meticulous process, PCA involves mounting electronic components onto a printed circuit board (PCB), creating a complete functioning system. These assemblies are used in a wide range of applications, including computer systems, mobile devices, automotive electronics, aerospace equipment, medical devices, and industrial machinery.Technological Advancements Driving Growth:Advancements in technology have played a pivotal role in fueling the growth of the PCA industry. The development of smaller and more powerful electronic devices has demanded highly intricate PCB assemblies, featuring compact designs and efficient functionality. As a result, manufacturers are continuously striving to innovate and incorporate new materials, designs, and assembly techniques to meet the evolving requirements.Moreover, the emergence of Internet of Things (IoT) and the increasing interconnectedness of devices have further propelled the demand for advanced PCA solutions. IoT technology relies heavily on reliable and efficient PCA systems to ensure seamless connectivity and interoperability among devices, driving the growth of the industry.Application in Various Sectors:The application of PCA reaches beyond consumer electronics. Industries such as automotive, aerospace, healthcare, and telecommunications all heavily rely on PCA technology to enable their operations. In the automotive sector, PCA plays a vital role in advanced driver-assistance systems (ADAS), vehicle infotainment systems, and powertrain control modules. The aerospace industry utilizes high-performance PCA technology in avionics systems, navigation systems, and communication devices, ensuring safe and efficient air travel.Furthermore, the healthcare sector benefits greatly from PCA, as it is critical in medical imaging devices, patient monitoring systems, and surgical equipment. Telecommunication equipment, including base station infrastructure, smartphones, and data centers, also rely on robust PCA technology for efficient network communication and data management.Market Outlook:The global Printed Circuit Assembly market is expected to witness substantial growth in the coming years. The rising demand for electronic devices, coupled with continuous technological advancements, is paving the way for the expansion of PCA industry. According to industry reports, the market is projected to grow at a CAGR of X% from 2021 to 2026.However, the industry is not without its challenges. The increasing complexity of PCB designs and the miniaturization of electronic components present significant technical hurdles for manufacturers. Ensuring the quality and reliability of PCB assemblies while meeting strict regulatory guidelines is another crucial aspect that manufacturers need to address.Conclusion:The Printed Circuit Assembly industry has emerged as a vital component of the electronic manufacturing ecosystem, driving technological advancements and enhancing the capabilities of various sectors. Through continuous innovation, manufacturers are striving to meet the ever-increasing demands for smaller, faster, and more efficient electronic devices.As the demand for electronic devices continues to soar, the PCA industry will play a significant role in enabling the production of high-quality, reliable, and interconnected electronic systems. With further advancements in technology and a focus on improving manufacturing processes, the Printed Circuit Assembly industry is well-equipped to meet the evolving needs of the digital age.

An Overview of Lean Production and Its Impact on Manufacturing

Lean Production: The Future of Manufacturing in [Company Name][Company Name], a leading manufacturing company, is set to revolutionize the industry with the implementation of Lean Production techniques. With a focus on efficiency, quality, and waste reduction, Lean Production is set to streamline operations and drive the company towards a more sustainable and profitable future.Lean Production is a method derived from the Toyota Production System, which focuses on minimizing waste and maximizing value for the customer. It is based on the principles of continuous improvement, eliminating waste, and empowering employees to make decisions that contribute to the overall success of the company.In [Company Name], the adoption of Lean Production is driven by the desire to create a more efficient and responsive manufacturing process. By eliminating unnecessary steps, reducing inventory, and improving workflow, the company aims to deliver high-quality products to customers in a timely manner, while also reducing costs and environmental impact.One of the key elements of Lean Production is the concept of "Just-in-Time" manufacturing, which involves producing only what is needed, when it is needed, and in the quantity needed. This approach minimizes inventory holding costs and reduces the risk of obsolete inventory, while also allowing the company to be more responsive to changes in customer demand.In addition to "Just-in-Time" manufacturing, [Company Name] is also implementing other Lean tools and techniques, such as value stream mapping, 5S methodology, and Kaizen events. These practices will help identify and eliminate waste, standardize work processes, and foster a culture of continuous improvement within the organization.Furthermore, [Company Name] is investing in employee training and development to ensure that all staff are equipped with the skills and knowledge needed to support the Lean Production system. By empowering employees to identify and solve problems on the production floor, the company is fostering a culture of collaboration and innovation that will further drive the success of Lean Production implementation.With Lean Production, [Company Name] is not only focusing on improving its manufacturing processes, but also on creating a more sustainable and environmentally-friendly operation. By reducing waste, energy consumption, and emissions, the company is committed to minimizing its environmental impact and contributing to a greener future.As a result of the implementation of Lean Production, [Company Name] is confident that it will see significant improvements in its operations, including reduced lead times, improved product quality, and increased productivity. These improvements will ultimately benefit the company's bottom line, as well as its customers and employees.[Company Name]'s commitment to Lean Production is a testament to its dedication to innovation, efficiency, and sustainability. By embracing these principles, the company is setting itself up for long-term success in an increasingly competitive market.In conclusion, Lean Production is set to revolutionize the manufacturing industry, and [Company Name] is at the forefront of this transformation. With a firm commitment to efficiency, quality, and waste reduction, the company is poised to thrive in the rapidly changing business landscape. The implementation of Lean Production in [Company Name] is a testament to its dedication to innovation, efficiency, and sustainability, and it sets an example for other companies to follow in the pursuit of operational excellence.

Top Pcb Prototype Supplier for Your Business Needs

[Company Name] is proud to announce its latest partnership with a leading PCB prototype supplier. This collaboration is set to revolutionize the electronics manufacturing industry by providing customers with high-quality prototypes and fast turnaround times.As a leading manufacturer of electronic components, [Company Name] has always strived to stay ahead of the curve when it comes to innovation and technology. With the rapid advancements in the electronics industry, it is essential for companies to have access to reliable and efficient PCB prototype suppliers. This is where the partnership with the PCB prototype supplier comes into play.The PCB prototype supplier is known for its state-of-the-art facilities and cutting-edge technology, which allows for the production of high-quality prototypes with quick turnaround times. This aligns perfectly with [Company Name]'s commitment to providing its customers with the best possible products and services. With this partnership, customers can expect to receive top-notch prototypes that meet their exact specifications, all while benefiting from the expertise and experience of both [Company Name] and the PCB prototype supplier.One of the key advantages of this partnership is the ability to streamline the prototype production process. By working closely with the PCB prototype supplier, [Company Name] can ensure that the prototypes are produced efficiently and to the highest standards. This not only saves time but also reduces the likelihood of errors or issues with the prototypes, ultimately leading to a smoother and more efficient manufacturing process.Furthermore, this partnership allows [Company Name] to expand its range of prototype options. The PCB prototype supplier offers a wide variety of materials, finishes, and technologies, which means that customers can now access an even greater selection of prototypes to suit their specific needs. Whether it's a simple single-layer prototype or a complex multi-layer design, customers can rest assured that they have access to the best possible options through this collaboration.In addition to the expanded range of options, customers can also benefit from cost savings. By partnering with a leading PCB prototype supplier, [Company Name] is able to negotiate competitive pricing for prototype production. This means that customers can enjoy high-quality prototypes at a more affordable rate, ultimately helping them to save on production costs and improve their bottom line.This collaboration also has a strong emphasis on customer service and support. Both [Company Name] and the PCB prototype supplier are committed to providing excellent customer service, ensuring that customers receive the support and assistance they need throughout the prototype production process. Whether it's technical guidance, design consultations, or troubleshooting, customers can rely on the expertise and knowledge of both companies to help them every step of the way.Overall, this partnership represents a significant step forward for [Company Name] and its commitment to delivering the best possible products and services to its valued customers. By working with a leading PCB prototype supplier, [Company Name] is able to enhance its prototype capabilities, streamline production processes, expand its range of options, and provide cost savings to its customers. As a result, customers can expect to receive the highest quality prototypes with fast turnaround times, all backed by exceptional customer service and support.With this collaboration, [Company Name] is well positioned to lead the way in the electronics manufacturing industry and continue to meet the evolving needs of its customers. The future looks bright for [Company Name] and its customers, thanks to this exciting new partnership with the PCB prototype supplier.

Factories specializing in Cob Chip On Board technology

Cob Chip On Board Factories, or COB factories, have been making waves in the electronics manufacturing industry in recent years. These factories are known for their advanced manufacturing processes and cutting-edge technology, which have made them a popular choice for companies looking to produce high-quality electronic components.One such COB factory that has been making headlines is {} located in the heart of the electronic manufacturing hub. {} is a leading manufacturer of COB components and has gained a reputation for its unparalleled quality and innovation.The company's state-of-the-art manufacturing facility is equipped with the latest technology, and its team of highly skilled engineers and technicians are constantly working to improve their production processes. As a result, {} is able to produce COB components that are not only of the highest quality, but also highly efficient and reliable.One of the key advantages of COB technology is its ability to produce compact and high-performance components. By integrating multiple LED chips onto a single board, COB technology allows for a more efficient use of space and a reduction in overall component size. This makes COB components ideal for a wide range of electronic devices, from smartphones and tablets to automotive and industrial applications.Another important benefit of COB technology is its superior thermal management. By combining multiple LED chips on a single board, COB components are able to distribute heat more effectively, resulting in lower operating temperatures and increased longevity. This is particularly important in applications where heat dissipation is a critical factor, such as in automotive and industrial lighting.In addition to these advantages, COB technology also offers higher lumen output and improved color rendering compared to traditional LED components. This makes COB components an attractive choice for applications that require high-quality, bright and uniform lighting, such as commercial and residential lighting, as well as outdoor and architectural lighting.The demand for COB components is rapidly growing, and {} has positioned itself as a leading supplier in the market. The company's commitment to quality and innovation has led to partnerships with some of the biggest names in the electronics industry, and its COB components can be found in a wide range of products worldwide.Despite the challenges posed by the ongoing global pandemic, {} has continued to invest in its manufacturing capabilities and expand its product offerings. The company's dedication to research and development has resulted in the introduction of new and improved COB components, as well as the expansion of its production capacity to meet the increasing demand.As the electronics industry continues to evolve, COB technology is expected to play a crucial role in shaping the future of electronic components. With its unparalleled quality and innovation, {} is well-positioned to lead the way in this exciting field, and is poised to remain at the forefront of COB manufacturing for years to come.

Top 5 Circuit Card Assembly Suppliers in the Market Today

Circuit Card Assembly Supplier, a leading provider of high-quality circuit card assembly solutions for various industries, continues to impress customers with their innovative and reliable products. With their state-of-the-art manufacturing facilities and commitment to delivering exceptional service, Circuit Card Assembly Supplier has solidified its position as a trusted partner for companies seeking top-notch electronic components.Established in [year], Circuit Card Assembly Supplier has been at the forefront of the circuit card assembly industry for over [number] years. Their extensive experience and expertise enable them to meet the diverse needs of their clients, from small businesses to large corporations. The company takes pride in its ability to deliver custom solutions that are tailored to the specific requirements of each customer, ensuring that their products integrate seamlessly into various applications.One of the key factors that set Circuit Card Assembly Supplier apart from its competitors is their relentless pursuit of excellence. The company is constantly investing in cutting-edge technologies and industry-leading equipment to enhance their manufacturing capabilities. This commitment to innovation enables Circuit Card Assembly Supplier to stay ahead of the curve and provide customers with the latest advancements in circuit card assembly.In addition to their focus on technology, Circuit Card Assembly Supplier places a strong emphasis on quality control. The company adheres to the highest standards of quality throughout the production process, from procurement of raw materials to final inspection. By implementing rigorous quality assurance measures, Circuit Card Assembly Supplier ensures that every product that leaves their facility meets the strictest performance and reliability standards.Furthermore, Circuit Card Assembly Supplier is dedicated to fostering strong relationships with their clients. The company employs a team of knowledgeable and skilled professionals who work closely with customers to understand their unique requirements and provide personalized support. This customer-centric approach has earned Circuit Card Assembly Supplier a reputation for outstanding service and support, leading to long-term partnerships with many of their clients.One of Circuit Card Assembly Supplier's standout offerings is their turnkey solution for circuit card assembly. This comprehensive service includes everything from design and prototyping to full-scale production and testing. By offering a complete suite of services, Circuit Card Assembly Supplier simplifies the manufacturing process for their customers, saving them time and resources while ensuring the highest level of quality and consistency.Recently, Circuit Card Assembly Supplier has expanded its production capacity to meet the growing demand for their products. The company has added new manufacturing lines and increased its workforce to accommodate the surge in orders. This expansion enables Circuit Card Assembly Supplier to fulfill larger and more complex projects while maintaining their trademark efficiency and precision.Looking ahead, Circuit Card Assembly Supplier is poised to continue its upward trajectory in the circuit card assembly industry. The company is exploring new opportunities for growth and diversification, seeking to broaden its product range and expand into emerging markets. With their unwavering commitment to excellence and customer satisfaction, Circuit Card Assembly Supplier is well-positioned to remain a leading force in the electronic components sector.In conclusion, Circuit Card Assembly Supplier stands as a testament to the thriving potential of the circuit card assembly industry. Through their dedication to quality, innovation, and customer service, Circuit Card Assembly Supplier has established itself as a go-to partner for businesses in need of reliable and high-performance electronic components. As the company presses forward with its expansion and development plans, it is clear that Circuit Card Assembly Supplier will continue to play a pivotal role in shaping the future of circuit card assembly technology.

Expert Tips for Printed Wiring Board Assembly and Production

Printed Wiring Board Assembly is a crucial component in the electronics industry, and one company that has been leading the way in this field is {}.{} is a globally renowned company that specializes in the design and manufacturing of high-quality printed wiring board assemblies. With a strong focus on innovation and cutting-edge technology, they have been providing top-notch solutions to their clients for many years. Their commitment to excellence and dedication to customer satisfaction have earned them a sterling reputation in the industry.The company's printed wiring board assembly services cover a wide range of applications, including telecommunications, automotive, aerospace, and consumer electronics. They have a team of skilled engineers and technicians who are experts in the field and work tirelessly to ensure that every product meets the highest standards of quality and reliability.One of the key factors that set {} apart from the competition is their state-of-the-art manufacturing facilities. They have invested heavily in the latest equipment and technology to ensure that they can deliver the most advanced and efficient solutions to their clients. This commitment to staying ahead of the curve has allowed them to consistently exceed customer expectations and maintain their position as an industry leader.In addition to their cutting-edge manufacturing capabilities, {} also places a strong emphasis on quality control. They have stringent processes in place to ensure that every printed wiring board assembly that leaves their facility is free from defects and built to last. This attention to detail is one of the reasons why their clients trust them with their most critical projects.Another aspect of {} that sets them apart is their commitment to sustainability. They are dedicated to minimizing their environmental impact and have implemented a range of initiatives to reduce waste and energy consumption. This eco-friendly approach has not only benefited the environment but has also helped them to streamline their operations and drive down costs, ultimately resulting in more competitive pricing for their clients.{}'s dedication to excellence and innovation has not gone unnoticed, as they have received numerous accolades and awards for their work in the printed wiring board assembly industry. Their commitment to pushing the boundaries of what is possible in electronics manufacturing has earned them a loyal customer base and positioned them as a go-to partner for companies looking for high-quality solutions.Looking ahead, {} has ambitious plans for the future. They are constantly exploring new technologies and techniques to further improve their printed wiring board assembly services. They are also committed to expanding their global reach and serving clients in new markets around the world. With their proven track record of success and their unwavering commitment to excellence, it's clear that {} will continue to lead the way in the printed wiring board assembly industry for many years to come.

Top Circuit Board Suppliers on the Market

Smt Circuit Board Suppliers (company name removed) is a leading provider of high-quality circuit boards for a variety of industries. With a commitment to excellence and innovation, the company has established itself as a trusted partner for businesses seeking reliable and cost-effective solutions for their electronic manufacturing needs.The company specializes in surface mount technology (SMT) circuit boards, which are widely used in the production of electronic devices such as mobile phones, computers, and medical equipment. These boards are designed to be compact, lightweight, and durable, making them ideal for a wide range of applications.Smt Circuit Board Suppliers prides itself on its state-of-the-art manufacturing facilities, which are equipped with the latest technology and automated processes to ensure the highest level of precision and consistency in every circuit board produced. The company's team of experienced engineers and technicians work closely with clients to understand their specific requirements and develop customized solutions that meet their exact specifications.In addition to its cutting-edge manufacturing capabilities, Smt Circuit Board Suppliers is also committed to sustainability and environmental responsibility. The company has implemented strict quality control measures to minimize waste and reduce its carbon footprint, and it continuously explores new ways to improve efficiency and resource utilization in its operations.With a strong focus on customer satisfaction, Smt Circuit Board Suppliers offers a range of value-added services, including design assistance, prototyping, and testing to ensure that every circuit board meets the highest standards of quality and reliability. The company also provides comprehensive technical support and responsive customer service to address any issues or concerns that may arise during the manufacturing process.Smt Circuit Board Suppliers serves a diverse clientele, including manufacturers in the telecommunications, automotive, aerospace, and consumer electronics industries. The company's ability to deliver superior products and exceptional service has earned it a reputation as a preferred partner for businesses seeking dependable and cost-effective circuit board solutions.In a recent development, Smt Circuit Board Suppliers has announced plans to expand its production capacity to meet the growing demand for its products. The company has invested in new equipment and technology to increase its manufacturing capabilities, and it has also expanded its workforce to support its growth initiatives."We are excited to announce the expansion of our production facilities to better serve our clients' needs," said [Name], CEO of Smt Circuit Board Suppliers. "This investment reflects our commitment to providing the highest quality circuit boards and outstanding service to our customers."The expansion will allow Smt Circuit Board Suppliers to take on larger orders and accommodate more complex projects, positioning the company for continued success and growth in the competitive electronic manufacturing industry.As Smt Circuit Board Suppliers continues to expand its footprint in the market, the company remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. By staying at the forefront of technological advancements and maintaining a customer-centric approach, the company is well positioned to meet the evolving needs of the electronic manufacturing industry and maintain its position as a leader in the market.In conclusion, Smt Circuit Board Suppliers is a trusted provider of high-quality SMT circuit boards, known for its commitment to excellence, innovation, and customer satisfaction. With its expansion plans and continued dedication to technological advancement, the company is poised for continued success and growth in the electronic manufacturing industry.

Get the Latest Lead Free PCB Assembly Technology for Your Electronic Devices

Lead-free PCB assembly has become a growing trend in the electronics industry as more companies are making the transition to more environmentally friendly practices. This shift is not only beneficial for the environment but also for the health and safety of workers who are involved in the manufacturing process.One company at the forefront of this movement is {}. They have been a leader in the PCB assembly industry for many years and have recently made the transition to lead-free manufacturing. This decision reflects their commitment to sustainability and their desire to provide high-quality products that are safe for both consumers and the environment.Lead is a toxic metal that has been widely used in the electronics industry for decades. It can cause a range of health issues, including developmental delays in children and neurological problems in adults. In addition, lead can contaminate the environment and pose a threat to wildlife and ecosystems. As a result, there has been a growing push for companies to eliminate lead from their manufacturing processes.{} recognized the importance of this issue and took the necessary steps to transition to lead-free PCB assembly. This involved investing in new equipment and training their staff to ensure that they could continue to produce high-quality products while adhering to the new standards.Lead-free PCB assembly requires a shift to alternative materials and manufacturing processes. For example, lead-free solder must be used in place of traditional lead-based solder. This solder is made from a combination of metals such as tin, silver, and copper, which are not only safer for workers and consumers but also have a lower impact on the environment.In addition to using lead-free solder, {} has also implemented other environmentally friendly practices in their manufacturing process. This includes reducing waste and energy consumption, as well as recycling materials whenever possible. These efforts have helped to minimize the company's environmental footprint and align with their commitment to sustainable business practices.By making the transition to lead-free PCB assembly, {} has positioned themselves as a leader in the industry and set a positive example for other companies to follow. They have demonstrated that it is possible to produce high-quality products without compromising on environmental and worker safety.The decision to transition to lead-free manufacturing reflects {}’s dedication to producing innovative and sustainable products. Their commitment to environmental stewardship and worker safety has set them apart as a responsible and forward-thinking company in the electronics industry.With the increasing demand for lead-free products, {} is poised to continue their success and make a positive impact on the environment and the industry as a whole. Their dedication to sustainability and their willingness to embrace new technologies and practices will undoubtedly lead to a brighter and cleaner future for the electronics industry.

Top Bonding Factories for Gold Ribbon Manufacturing

Gold Ribbon Bonding Factories is a leading manufacturer in the bonding industry, specialising in the production of high-quality adhesive products. With a strong commitment to research and development, the company has established a reputation for innovation and excellence in the market.Founded in 1995, Gold Ribbon Bonding Factories has grown to become a trusted name in the bonding industry. The company has a strong focus on quality and reliability, and its products are used in a wide range of applications, including automotive, construction, electronics, and packaging.The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for efficient production and consistent quality control. Gold Ribbon Bonding Factories is committed to sustainability and environmental responsibility, and has implemented environmentally-friendly practices across its operations.One of the key strengths of Gold Ribbon Bonding Factories is its dedicated team of professionals. The company employs a highly-skilled workforce with expertise in chemistry, engineering, and material science. This team is committed to delivering innovative solutions and superior customer service, and plays a crucial role in the company's success.Gold Ribbon Bonding Factories operates with a customer-centric approach, and works closely with clients to understand their specific needs and requirements. The company offers customised solutions to meet the unique demands of each customer, and prides itself on delivering superior products and service.In addition to its manufacturing capabilities, Gold Ribbon Bonding Factories also offers comprehensive technical support and consultancy services. The company's team of experts provides guidance on product selection, application methods, and troubleshooting, ensuring that customers achieve optimal results with Gold Ribbon Bonding Factories' products.The company's commitment to innovation is evident in its continuous investment in research and development. Gold Ribbon Bonding Factories is constantly exploring new materials, technologies, and processes to stay ahead of market trends and meet evolving customer needs.Gold Ribbon Bonding Factories takes pride in its adherence to the highest quality standards. The company is certified to ISO 9001 and ISO 14001, demonstrating its commitment to quality management and environmental responsibility. This certification ensures that Gold Ribbon Bonding Factories' products are manufactured to the highest standards of quality and safety.The company's dedication to excellence has earned it a strong reputation in the market, and Gold Ribbon Bonding Factories is widely regarded as a reliable and trusted partner. Its products are used by leading companies across various industries, and the company has built long-lasting relationships with its customers based on mutual trust and satisfaction.Moving forward, Gold Ribbon Bonding Factories is poised for further growth and success. The company continues to invest in research and development, expand its product range, and explore new market opportunities. With its strong focus on quality, innovation, and customer satisfaction, Gold Ribbon Bonding Factories is well-positioned to maintain its leadership in the bonding industry.