- Home

- Pcb Assembly Testing Methods

Comprehensive Guide to PCB Assembly Testing Methods - Manufacturer

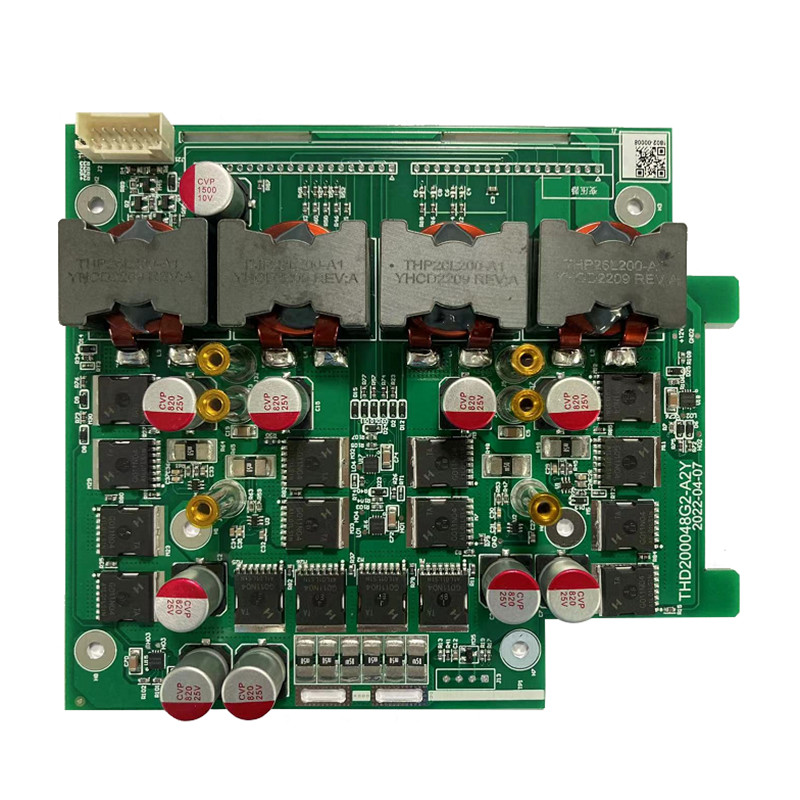

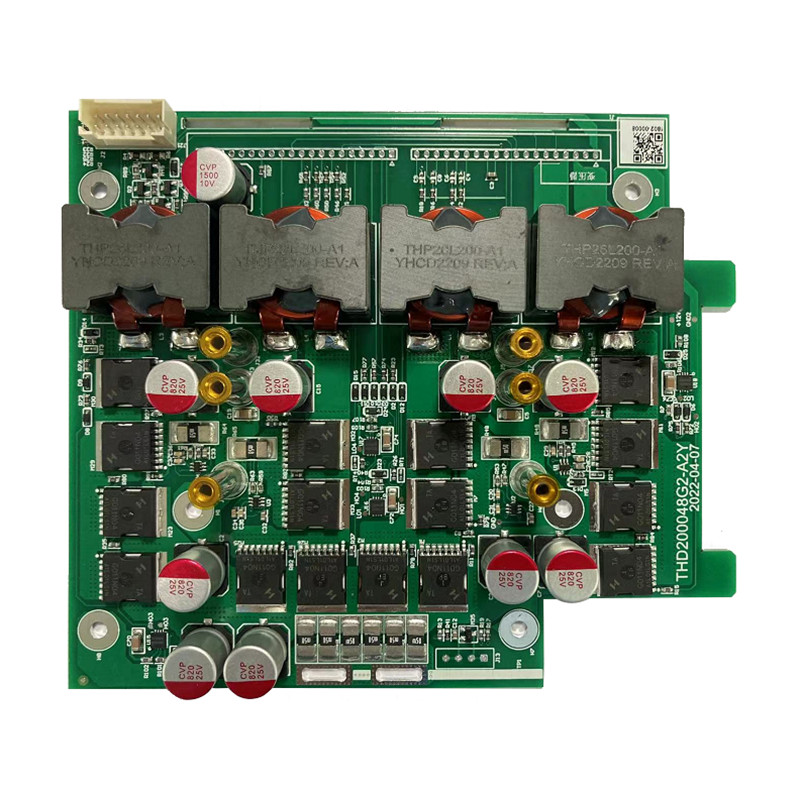

Introducing Zhuhai Xinrunda Electronics Co., Ltd., the leading manufacturer, supplier, and factory based in China, specializing in PCB Assembly Testing Methods. With a strong commitment to quality and innovation, our company offers a wide range of cutting-edge testing solutions to ensure the flawless functionality of PCB assemblies.

At Zhuhai Xinrunda Electronics Co., Ltd., we understand the criticality of reliable testing methods for PCB assemblies. Our dedicated team of experts has developed advanced techniques to identify potential flaws, defects, or malfunctions during the production process. With our state-of-the-art testing equipment and comprehensive procedures, we guarantee the highest level of accuracy and precision.

Our PCB Assembly Testing Methods encompass a variety of approaches, including visual inspection, automated optical inspection (AOI), in-circuit testing (ICT), functional testing (FCT), and more. From initial design verification to final product validation, our testing methods play a pivotal role in ensuring optimum performance and durability.

With years of experience in the industry, Zhuhai Xinrunda Electronics Co., Ltd. has become a trusted name when it comes to PCB Assembly Testing Methods in China and beyond. As a customer-focused company, we prioritize providing exceptional services and tailor-made solutions to meet your specific testing requirements.

Choose Zhuhai Xinrunda Electronics Co., Ltd. as your reliable partner for superior PCB Assembly Testing Methods. Contact us today for more information and let us assist you in achieving flawless PCB assemblies!

Zhuhai Xinrunda Electronics Co,. Ltd.

Company News

Related News

Medical PCB Assembly Service

Looking for reliable Medical PCB Assembly Service? Look no further! We are a factory offering top-notch assembly solutions for medical device manufacturers.

Automotive PCB Assembly Service

Looking for top-notch Automotive PCB Assembly Service? Look no further! We are a factory specializing in high-quality assembly, guaranteeing reliability and efficiency.

New Energy PCB Assembly Service

Looking for a reliable factory offering top-notch New Energy PCB Assembly Service? Look no further! Trust our expertise and experience for all your electronic manufacturing needs.

Electrical & Power PCB Assembly Service

Looking for professional Electrical & Power PCB Assembly Service? Look no further! We are a factory specializing in top-quality assembly solutions.

Consumer Electronics PCB Assembly Service

We are a leading factory offering top-notch Consumer Electronics PCB Assembly Service. Count on our expertise and quality for all your assembly needs.

Lfestyle Equipment PCB Assembly Service

Choose our Lifestyle Equipment PCB Assembly Service! We are a factory specializing in high-quality electronic assembly. Trust us for efficient and reliable production.

Automated Products PCB Assembly Service

Get high-quality PCB assembly service for your automated products from our factory. We specialize in efficient and cost-effective manufacturing solutions.

Industrial Instrument PCB Assembly Service

Looking for reliable industrial instrument PCB assembly service? Look no further! We are a dedicated factory, offering high-quality PCB assembly solutions.

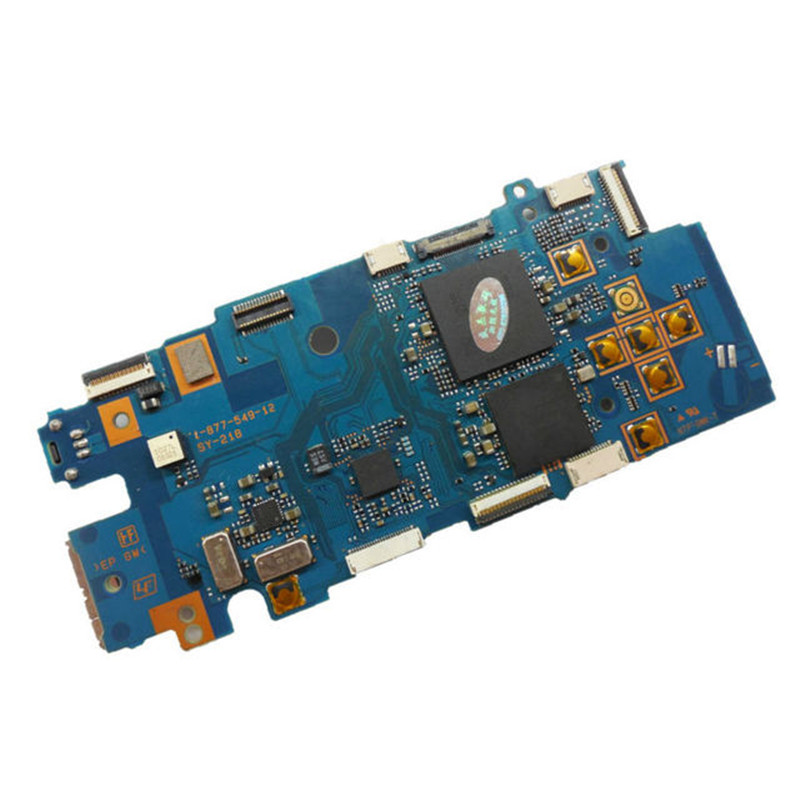

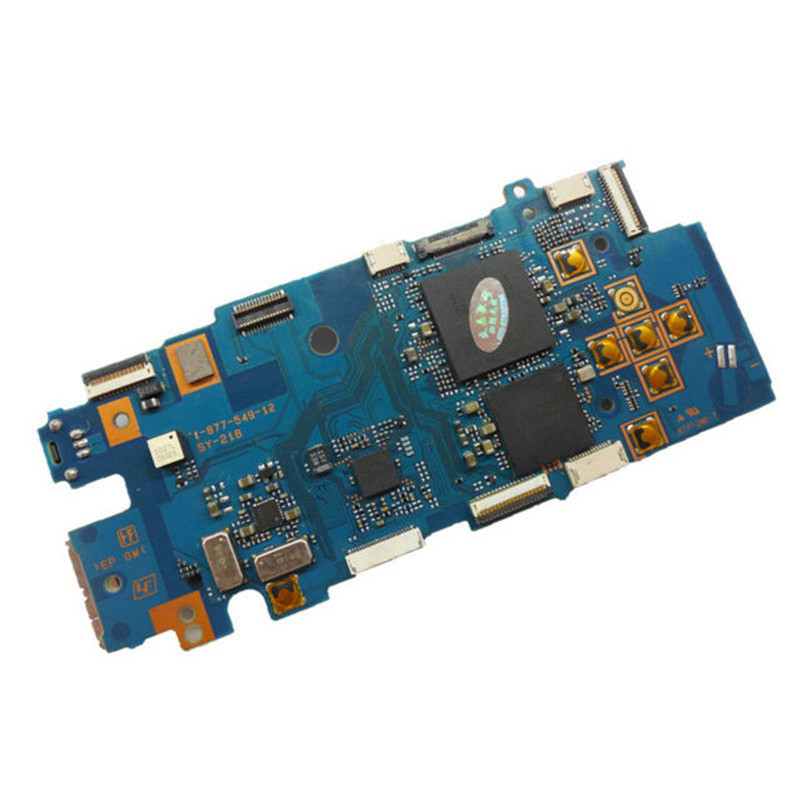

Phone Electronics PCB Assembly Service

Get high-quality phone electronics PCB assembly service from our factory. We specialize in efficient production processes to ensure top-notch products.

One-Stop PCB Assembly Service

One-Stop PCB Assembly Service - Simplify your production process with our factory-direct solution. Get high-quality PCB assembly done efficiently at competitive prices.

Artificial Intelligence PCB Assembly Service

Experience top-notch AI PCB assembly services at our factory. We offer advanced technology and expertise for efficient production and high-quality products.

Intelligent Digital PCB Assembly Service

Experience seamless Intelligent Digital PCB Assembly Service with our factory. Trust us for reliable, precise and efficient manufacturing solutions.

Communication PCB Assembly Service

Get top-notch Communication PCB Assembly Service from our factory. We offer reliable and efficient solutions for all your communication circuit board needs. Contact us now!

- Effective PCB Assembly Testing Methods | Top Manufacturer

- Reviews

- Related Videos

Introducing our state-of-the-art PCB Assembly Testing Methods! As technology continues to evolve, it is crucial for electronic devices to undergo rigorous testing to ensure their reliability and performance. Our advanced testing methods ensure that every printed circuit board (PCB) meets the highest quality standards before reaching our customers. Our PCB Assembly Testing Methods encompass a comprehensive suite of techniques that guarantee the functionality and durability of each PCB. From initial prototyping to the final manufacturing stage, our testing procedures are designed to identify any manufacturing defects or faulty components, allowing for swift and effective corrective measures. One of our primary testing methods is Automated Optical Inspection (AOI), which employs high-resolution cameras and image recognition software to inspect every aspect of the PCB for potential defects. This technology swiftly identifies issues such as missing components, misalignments, or soldering defects, ensuring a high-quality end product. In addition to AOI, we utilize In-Circuit Testing (ICT) to meticulously examine the electrical characteristics of the PCB. By inserting probes at various points on the board, ICT analyzes the functionality of individual components and circuit connections. This thorough testing method is an integral part of our quality control process, uncovering hidden issues that may affect the overall performance of the PCB. To ensure the reliability of our products in real-world environments, we also conduct Environmental Stress Screening (ESS). By exposing the assembled PCBs to extreme temperatures, vibrations, and other challenging conditions, we simulate the harsh environments they may encounter during their lifespan. This rigorous testing guarantees that our PCBs can withstand demanding operational conditions without compromising their functionality. At our company, customer satisfaction is our utmost priority. By implementing cutting-edge PCB Assembly Testing Methods, we assure our customers of high-quality, reliable products that will stand the test of time.

I recently purchased a PCB assembly testing kit and it has been a game-changer for me. This kit provides a comprehensive range of testing methods to ensure the proper functioning of PCB assemblies. The testing methods included are highly efficient and accurate, allowing me to identify any potential defects or errors in the assembly process. With this kit, I can easily perform in-circuit testing, functional testing, and boundary scan testing. The results are reliable and the kit is user-friendly, making it easy to navigate through the testing process. I highly recommend this PCB assembly testing kit for anyone in need of reliable and efficient testing methods.

When it comes to PCB assembly testing methods, look no further than our product. Our PCB assembly testing methods are top-notch, ensuring the highest level of quality and reliability. With advanced technologies and state-of-the-art equipment, we guarantee accurate and comprehensive testing. From functional testing to in-circuit testing, our product covers it all. It is designed to detect any possible faults or defects, minimizing the risk of failure and increasing overall performance. With our PCB assembly testing methods, you can rest assured that your product will meet the highest standards. Invest in our product and experience the peace of mind knowing that your PCB assembly is thoroughly tested and ready to deliver exceptional results.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours