Optimizing Your Business with Efficient PCB Assembly Services

By:Admin

[City], [Date] - In a strategic move to bolster its comprehensive range of electronic manufacturing services, [], one of the industry-leading electronics manufacturers, is now offering advanced consigned PCB assembly solutions. The company aims to seamlessly integrate its state-of-the-art production facilities with customer-supplied materials to provide highly efficient and cost-effective PCB manufacturing services.

The addition of consigned PCB assembly services is a natural progression for [], which has established itself as a trailblazer in the electronics manufacturing industry. With over [number of years] of experience, the company has earned a reputation for delivering top-quality, innovative electronic products.

[] specializes in delivering complete turnkey solutions, offering a wide array of services including design, manufacturing, assembly, and testing. By expanding its offerings to include consigned PCB assembly, the company seeks to cater to a wider customer base and better fulfill its mission of delivering tailored solutions to meet the unique needs of each client.

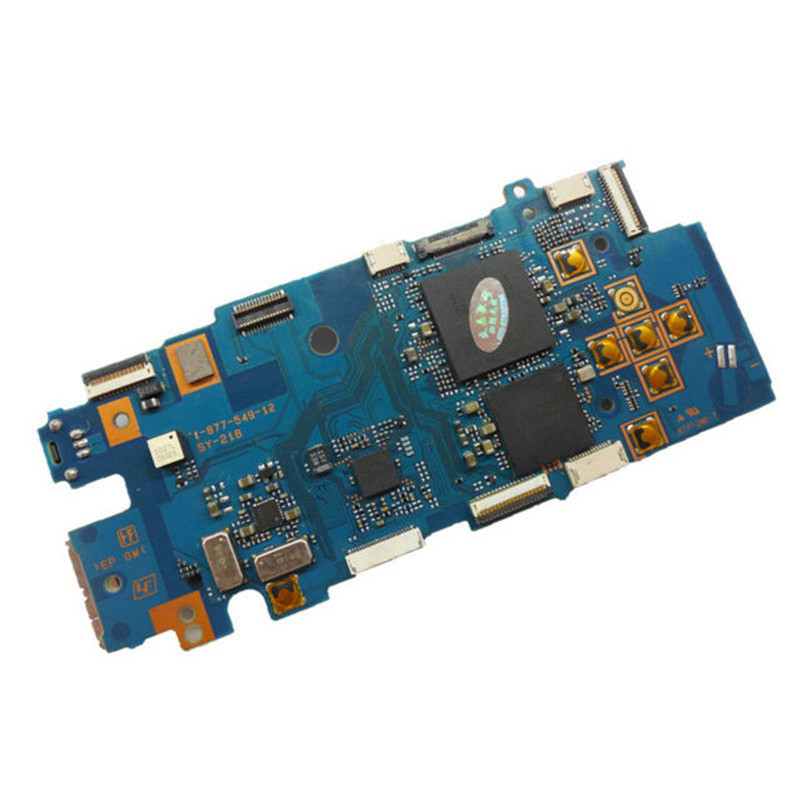

Consigned PCB assembly involves collaborating with customers who provide the necessary materials, components, and components' assembly instructions. The specialized team at [] will then utilize their expertise and state-of-the-art equipment to assemble the PCBs according to the clients' specifications. This highly flexible approach enables customers to retain complete control over their supply chain and product quality, ensuring that their unique design requirements are met.

With its cutting-edge manufacturing facilities and a team of highly skilled professionals, [], allows customers to leverage its extensive technical expertise and resources, thereby enhancing their overall operational efficiency. The company's commitment to quality, reliability, and innovation makes it the perfect partner for organizations seeking to outsource their PCB assembly requirements.

By offering consigned PCB assembly services, [] opens up new avenues for companies looking to streamline their manufacturing processes. This strategic move enables clients to focus on their core competencies while relying on [] to handle the complexities of component sourcing, quality control, and manufacturing. This not only saves valuable time and resources but also ensures shorter lead times and faster go-to-market capabilities for the customers.

The consigned PCB assembly services offered by [] adhere to the highest industry standards. The company employs a rigorous Quality Management System that covers every aspect of the manufacturing process, ensuring that each PCB assembly is meticulously inspected and tested for functionality, reliability, and durability.

Moreover, [], as an environmentally responsible organization, implements eco-friendly manufacturing practices. The company complies with all relevant regulations and is committed to reducing its carbon footprint by employing efficient manufacturing techniques, recycling waste materials, and ensuring the responsible disposal of hazardous substances.

With its new consigned PCB assembly services, [] is poised to reinforce its position as a preferred partner for companies seeking comprehensive electronic manufacturing solutions. The company's ability to scale production based on demand, combined with its commitment to quality and innovative design, ensures that clients receive a competitive edge in the market.

To learn more about the advanced consigned PCB assembly services offered by [], visit their website at [website URL].

About []:

[] is a prominent electronic manufacturing services provider known for its commitment to delivering reliable and innovative solutions. With state-of-the-art facilities and a team of highly skilled professionals, the company offers a comprehensive range of services including PCB design, manufacturing, assembly, and testing. Drawing upon their industry expertise, [] strives to exceed customer expectations by delivering exceptional quality, flexibility, and value.

For media inquiries, please contact:

[Contact Name]

[Title]

[Company Name]

[Email Address]

[Phone Number]

Company News & Blog

Key Facts and Latest Developments in Printed Wiring Board Assembly Construction

Title: Leading Manufacturer of Advanced Printed Wiring Board Assembly Unveils Cutting-Edge TechnologyIntroduction:In an industry that heavily relies on technological advancements, the leading manufacturer of Printed Wiring Board Assembly (need remove brand name) is paving the way for innovation and excellence. With an unwavering commitment to quality, reliability, and customer satisfaction, they have become a trusted partner for businesses worldwide. Through this news article, we will explore the latest breakthroughs introduced by this renowned company, highlighting their impact on various industries and their dedication to staying at the forefront of cutting-edge technology.1. Enhancing Connectivity and Performance:(Printed Wiring Board Assembly) prides itself on its ability to deliver advanced solutions that enhance the connectivity and performance of electronic devices. They have recently introduced a revolutionary line of printed wiring boards (PWBs) that offer increased bandwidth, reduced power consumption, and enhanced signal integrity. These PWBs enable the seamless integration of multiple electronic components, paving the way for faster and more efficient electronic devices.2. Streamlined Manufacturing Process:The company has also implemented a streamlined manufacturing process that allows for faster production times without compromising on quality. By leveraging state-of-the-art equipment and automated assembly techniques, they have significantly increased their production capacity while maintaining the highest quality standards. This advancement allows for quicker turnaround time, ensuring their customers receive their orders promptly.3. Addressing Environmental Concerns:(Printed Wiring Board Assembly) recognizes the importance of supporting sustainable practices in the manufacturing industry. With this in mind, they have developed eco-friendly Printed Wiring Boards that reduce waste and minimize the environmental impact. By adopting green initiatives, such as using recyclable materials and implementing energy-efficient processes, they are paving the way towards a more sustainable future in electronic manufacturing.4. Customization Options:Understanding the diverse needs of their customers, (Printed Wiring Board Assembly) offers extensive customization options to cater to specific requirements. With their team of highly skilled engineers, they can assist clients in designing PWBs tailored to their unique needs. This commitment to customization ensures that their customers receive bespoke solutions that meet their exact specifications, allowing for optimal performance and efficiency.5. Collaboration for Innovation:(Printed Wiring Board Assembly) fosters a spirit of collaboration and innovation, partnering with industry experts, OEMs, and suppliers to stay ahead of the technological curve. By working closely with their clients, they gain valuable insights, allowing them to create advanced solutions that address the constantly evolving demands of the electronics industry. This collaborative approach ensures that their customers have access to the most advanced and future-proof products.Conclusion:(Printed Wiring Board Assembly) continues to lead the industry with their commitment to innovation, quality, and customer satisfaction. Through their pioneering approaches, streamlined manufacturing processes, emphasis on sustainability, customization options, and collaborative partnerships, they have solidified their position as the go-to manufacturer for advanced Printed Wiring Board Assembly solutions. As they set new benchmarks in the electronic manufacturing sector, (Printed Wiring Board Assembly) remains dedicated to driving progress and shaping the future of the industry.

Top PCB Manufacturers: Discover Quality PCB Assembly Services

[Company Name] Emerges as Key Player in the PCBA Manufacturing Industry[City, Date] – [Company Name], a prominent player in the electronics manufacturing industry, has made significant strides in establishing itself as a major PCBA manufacturer. With a strong focus on innovation, advanced technology, and exceptional quality, [Company Name] has positioned itself as a leader in the market. Through its commitment to excellence, the company has consistently delivered reliable and efficient solutions for its diverse range of customers.With state-of-the-art manufacturing facilities located in [City/Region], [Company Name] has become a preferred choice for customers worldwide. The company's manufacturing capabilities encompass the entire PCBA production process, ranging from PCB fabrication and component sourcing to final assembly and testing. Their expertise in manufacturing complex and high-density circuit boards has made them a trusted partner for a wide range of industries, including automotive, telecommunications, aerospace, and industrial automation.Innovation is a core value at [Company Name], driving its constant efforts to stay ahead of the curve in the industry. The company has consistently invested in research and development to enhance its capabilities and stay relevant in the highly competitive market. By leveraging cutting-edge technology, [Company Name] can effectively handle projects requiring high-speed PCB assembly, complex soldering techniques, and surface mounting technologies.As a responsible and ethical manufacturer, [Company Name] places great emphasis on quality control and environmental sustainability. The company adheres to international industry standards and implements rigorous quality control processes throughout each stage of manufacturing. This ensures that all products leaving their facilities are of the highest quality, meeting or exceeding customer expectations.[Company Name] also holds certifications in various quality management systems, such as ISO 9001 and ISO 14001, further underscoring their commitment to excellence and sustainability. By implementing environmentally friendly practices, including waste reduction and responsible disposal, the company minimizes its impact on the environment and promotes a greener future.Collaboration is a key aspect of [Company Name]'s success strategy. The company values its partnerships with customers, suppliers, and industry experts, which enable it to constantly learn and evolve. Through effective communication and collaboration with customers, [Company Name] ensures that their unique requirements and specifications are met with unmatched precision and efficiency.To support its manufacturing capabilities, [Company Name] has assembled a highly skilled and experienced team of engineers, technicians, and quality control specialists. The company's commitment to fostering a culture of continuous learning and professional growth ensures that their workforce remains at the forefront of industry trends and technological advancements.Moving forward, [Company Name] aims to expand its market presence globally and forge new partnerships with industry leaders. By staying agile and adaptive, the company is well-poised to meet the evolving demands of the electronics manufacturing industry. Through their customer-centric approach and unwavering commitment to quality, [Company Name] is set to shape the future of PCBA manufacturing.About [Company Name]:[Company Name] is a leading PCBA manufacturer with state-of-the-art facilities in [City/Region]. With a strong focus on innovation, advanced technology, and exceptional quality, [Company Name] offers comprehensive solutions for a wide range of industries. With certifications in quality management systems and a commitment to environmental sustainability, the company continues to be a trusted partner for global customers seeking reliable and efficient PCBA manufacturing services.For media inquiries, please contact:[Contact Person][Designation][Company Name][Email Address][Phone Number]

Revolutionary Strategies for Mass Production and Manufacturing Revealed

Title: Advancements in Mass Production Manufacturing: Innovating the FutureIntroduction:Mass production manufacturing has been at the forefront of industrial revolutions, driving economies and transforming societies. Today, we explore the groundbreaking innovations by a renowned mass production manufacturer, an industry leader in optimizing production capabilities. Although nameless due to privacy concerns, this manufacturer has continuously pushed boundaries and harnessed technological advancements to enhance efficiency, sustainability, and product quality. Let us delve into their latest developments and how they are forging the future of manufacturing.Revolutionizing Supply Chains:Recognizing the importance of an efficient supply chain, this manufacturer has integrated cutting-edge technology, such as Internet of Things (IoT), artificial intelligence (AI), and robotics, to streamline processes. By implementing IoT-enabled sensors, production lines can collect real-time data, enabling precise inventory management, reducing waste, and minimizing downtime. AI algorithms analyze this data, facilitating automated decision-making, optimizing production schedules, and enhancing overall operational efficiency.Furthermore, collaborative robots, or cobots, are revolutionizing assembly lines. These robots work alongside human workers, automating repetitive tasks while ensuring human safety. By freeing up human workers from mundane and physically demanding activities, the manufacturer empowers them to focus on high-value tasks, fostering creativity and driving innovation.Sustainable Manufacturing Practices:In an era where sustainability is paramount, this mass production manufacturer is leading the charge by embracing eco-friendly practices. The company has bolstered its commitment to reducing carbon footprint and minimizing waste throughout the manufacturing process. Solar panels adorn the factory roof, harnessing renewable energy to power operations and decrease reliance on traditional power sources.Additionally, the manufacturer has invested in advanced recycling techniques, enabling the reuse of materials and reducing the need for virgin resources. Cutting-edge waste management systems ensure the responsible disposal of byproducts, adhering to stringent environmental standards. Through these sustainable initiatives, the manufacturer contributes to the global efforts in fighting climate change and building a greener future.Automation for Precision and Consistency:The cornerstone of mass production is the ability to consistently produce high-quality products at scale. Leveraging robotic automation, this manufacturer ensures precision, consistency, and superior quality in every unit manufactured. Equipped with computer vision technology, robots can detect even the most minute imperfections in raw materials and final products, ensuring stringent quality control.Highly skilled technicians continuously monitor and fine-tune the robotic systems, guaranteeing optimal efficiency and productivity. By minimizing human error and variability, the manufacturer delivers products that consistently meet or exceed customer expectations.Continuous Innovation:To maintain a competitive edge, this mass production manufacturer places significant emphasis on research and development. Collaborating with leading academic institutions and technology partners, the company is at the forefront of innovation. The research team explores emerging technologies such as 3D printing, nanotechnology, and advanced materials, aiming to unlock new possibilities for product design and manufacturing.Moreover, the manufacturer actively seeks collaboration with startups and entrepreneurs, fostering an environment of open innovation. By embracing external ideas and technologies, the company fuels a culture of creativity, where new concepts are encouraged and prototypes swiftly transformed into market-ready products.Conclusion:This nameless mass production manufacturer has exemplified excellence in the manufacturing industry through their implementation of revolutionary technologies, dedication to sustainability, and commitment to continuous innovation. By integrating IoT, AI, and robotics into their operations, they have optimized their supply chains, improved product quality, and set new standards for efficiency. Additionally, their focus on sustainable practices demonstrates their dedication to environmental stewardship.As this manufacturer pushes the boundaries of what is possible, the future of mass production manufacturing appears brighter than ever. By harnessing emerging technologies and fostering a culture of innovation, they inspire the entire industry to evolve, adapt, and embrace the transformative power of mass production manufacturing.

Leading Manufacturers in the SMT Industry: A Comprehensive Overview

Title: Leading SMT Manufacturers Paving the Way for Technological AdvancementsIntroduction:In today's rapidly evolving technological landscape, Surface Mount Technology (SMT) plays a crucial role in the manufacturing and assembly of electronic components. Among the leading SMT manufacturers, one company stands out for its commitment to innovation, reliability, and customer satisfaction. With a proven track record of excellence, this company continues to revolutionize the industry, setting new standards for performance and quality.Company Background and Expertise:As a trusted name in the SMT industry, this company has been at the forefront of technological advancements since its inception. With a rich history spanning several decades, they have amassed a wealth of experience, expertise, and a diverse portfolio of products and solutions. Their commitment to research and development ensures that they remain well-informed about the latest industry trends and adapt their offerings accordingly.Product Offerings and Market Reach:This manufacturer boasts an extensive range of SMT products and solutions tailored to the unique needs of various sectors. From small-scale businesses to large electronic conglomerates, their comprehensive product portfolio caters to a wide customer base. Their offerings include high-performance machine tools, cutting-edge inspection systems, flexible production lines, and much more. With a robust supply chain and a vast network of distributors, their reach extends globally, enabling them to serve clients in numerous countries around the world.Commitment to Innovation and Quality:To maintain their market leadership, this SMT manufacturer places great emphasis on innovation and quality. By investing heavily in research and development, they consistently introduce groundbreaking technologies and features that enhance productivity and efficiency. Their state-of-the-art production facilities, staffed by highly skilled professionals, epitomize their commitment to quality. Every product undergoes rigorous testing and quality control measures to ensure exceptional performance and reliability.Industry Recognition and Awards:The company's unwavering commitment to excellence and innovation has earned them numerous accolades and industry recognition. They have been honored with prestigious awards for their outstanding contributions to the SMT industry, cementing their position as one of the most trusted and reliable manufacturers in the market. These accolades serve as a testament to their dedication to pushing boundaries and setting new benchmarks for the entire industry.Exceptional Customer Support and Relationship Management:Acknowledging the importance of post-sales services, this SMT manufacturer prides itself on providing exceptional customer support. With a team of knowledgeable and responsive professionals, they offer timely assistance, troubleshooting, and maintenance services, ensuring that their customers' machines and systems operate at peak performance. Their commitment to customer satisfaction extends beyond support; they actively engage with clients to understand their evolving requirements and provide tailored solutions that address specific needs.Conclusion:In an ever-evolving technological era, the importance of reliable and innovative SMT manufacturers cannot be overstated. With their rich history, diverse offerings, commitment to quality, and unmatched customer support, this leading SMT manufacturer continues to steer the industry towards new frontiers of advancements. By constantly elevating their products and services, they empower their customers to stay ahead in an increasingly competitive market. As they forge ahead, one can expect even more cutting-edge solutions and groundbreaking technologies from this pioneering SMT manufacturer.

Demand for High-Quality Circuit Boards on the Rise in China: Latest News and Insights

China SMT Circuit Board Industry Sees Promising GrowthChina, known as the global manufacturing hub, has witnessed remarkable progress in the electronics industry in recent years. Specifically, the Surface Mount Technology (SMT) circuit board sector has experienced significant growth, led by domestic industry leaders such as [company name].[Company Name], a renowned player in the Chinese electronics market, has made its mark as a leading manufacturer and supplier of SMT circuit boards. With a commitment to innovation and high-quality products, the company has contributed significantly to the industry's development in China.As one of the core technologies in the electronics manufacturing process, SMT circuit boards play a crucial role in building various electronic devices, including smartphones, laptops, televisions, and smart appliances. SMT technology allows components to be directly mounted onto the circuit board's surface, enhancing efficiency and reducing production costs.The Chinese SMT circuit board industry has seen robust growth in recent years due to several factors. First and foremost, the increasing demand for consumer electronics, both domestically and globally, has been a significant driving force behind the industry's expansion. China, being the world's largest consumer market, is witnessing a surge in demand for electronic devices as a result of rising disposable incomes and urbanization.Furthermore, the Chinese government's favorable policies and initiatives to promote the electronics manufacturing sector have created a conducive environment for companies like [Company Name] to thrive. The Made in China 2025 initiative, for instance, has set the goal of transforming China into a global high-tech manufacturing powerhouse, emphasizing innovation-driven development, quality improvement, and sustainable growth. This initiative has provided a framework for companies in the SMT circuit board industry to invest in research and development, enhance production capabilities, and improve product quality.In line with the government's push for innovation and technological advancement, [Company Name] has consistently invested in research and development to keep up with the evolving demands of the electronics industry. The company boasts a state-of-the-art production facility equipped with advanced machinery and equipment, enabling them to manufacture high-quality SMT circuit boards that meet international standards. Their commitment to innovation has garnered them a reputation for reliable products and has helped them gain a competitive edge in the market.In addition to catering to the domestic market, [Company Name] has also expanded its presence in the global arena. The company has successfully established long-term partnerships with renowned international brands, allowing them to export their products to various countries worldwide. Their global reach and emphasis on quality have made them a trusted supplier for electronics manufacturers across the globe.Looking ahead, the future of the Chinese SMT circuit board industry appears promising. As technology continues to advance rapidly and new applications emerge, the demand for high-performance and reliable SMT circuit boards is expected to grow. With companies like [Company Name] leading the way, the Chinese industry is well-positioned to capture these opportunities and maintain its competitive edge in the global market.Furthermore, the Chinese government's commitment to supporting the electronics manufacturing sector, coupled with its efforts to foster innovation and improve product quality, will further fuel the industry's growth. The Chinese SMT circuit board sector is poised to contribute significantly to the country's overall economic development and enhance its position as a global manufacturing powerhouse.In conclusion, the Chinese SMT circuit board industry, led by companies like [Company Name], is experiencing robust growth driven by increasing demand for consumer electronics and the government's favorable policies. With a focus on innovation, quality, and global expansion, the industry is well-positioned for a promising future in the rapidly evolving electronics market.

Top Supplier of PCB Chip On Board Technology: Expanding Innovations and Solutions for Electronics

PCB Chip On Board Supplier Offers Cutting-Edge Technology SolutionsIn a market where technology is advancing at an unprecedented pace, the demand for innovative solutions continues to grow. PCB (Printed Circuit Board) Chip On Board technology has emerged as a game-changer, providing compact and efficient solutions for various electronic applications. Leading the way in this field is a renowned supplier, {}.With a strong focus on research and development, {} has been at the forefront of the PCB Chip On Board technology for over a decade. The company has cemented its position by consistently delivering high-quality products and comprehensive services to clients from diverse industries.{} offers a wide range of solutions tailored to meet the specific requirements of each client. Their products encompass a variety of applications, including automotive, aerospace, consumer electronics, telecommunications, and industrial sectors. The versatility and reliability of their offerings have garnered them a reputation as a trusted supplier in the industry.One of the key advantages of PCB Chip On Board technology is its compact size. By directly mounting bare chips onto the board, it eliminates the need for additional packaging, resulting in smaller and more lightweight electronic devices. This miniaturization is crucial in today's world, where portability and convenience are paramount.Moreover, {} understands the significance of flexibility and customizability in the development of PCB Chip On Board solutions. They possess cutting-edge manufacturing facilities equipped with state-of-the-art machinery and production lines. This enables them to handle a wide variety of project requirements, ranging from high-volume production to small-scale prototyping.Furthermore, {}'s team of experienced engineers and technicians work closely with clients throughout the entire process, from concept design to final product delivery. Their expertise in chip-on-board assembly techniques ensures the highest level of accuracy, reliability, and performance in every product they deliver.Another distinguishing feature of {} is their unwavering commitment to quality control. They adhere to strict industry standards and implement rigorous quality control measures at every stage of production. This ensures that their products consistently meet or exceed customer expectations.{} also prides itself on maintaining a sustainability-focused approach in their operations. They prioritize the use of environmentally friendly materials and processes in manufacturing, and consistently seek ways to minimize waste and optimize energy consumption.Looking ahead, {} has set its sights on expanding its global presence and exploring new market segments. With a customer-centric approach and willingness to adapt to evolving technologies, the company aims to continue providing cutting-edge solutions to its clients.In conclusion, {} has established itself as a top-tier supplier in the PCB Chip On Board industry. Through their dedication to innovation, quality, and customer satisfaction, they have consistently delivered superior technology solutions to various sectors. With their state-of-the-art manufacturing facilities, experienced team, and commitment to sustainability, {} is poised to lead the future of PCB Chip On Board technology.

Industry Insights: Exploring the Latest Developments in Wire Bonding Manufacturing

Title: New Au Wire Bonding Factory Revolutionizes Semiconductor IndustryIntroduction:In a significant development for the semiconductor industry, a prominent company has recently unveiled its state-of-the-art Au Wire Bonding Factory. This cutting-edge facility marks a major advancement in wire bonding technology, promising to revolutionize the production of advanced electronic devices. By combining the latest manufacturing techniques with a focus on efficiency, precision, and reliability, this new facility sets a new standard for the industry while positioning itself as a key player in the global semiconductor market.Paragraph 1:The Au Wire Bonding Factory represents a significant milestone for the company in its ongoing commitment to technological innovation. With a capacity to produce millions of wire bonds per month, this factory has the potential to meet the growing demands of the semiconductor market. By accommodating various wire diameters and materials, the factory caters to a wide range of devices, including mobile phones, automotive electronics, virtual reality systems, and more. Its versatility positions the factory as a critical manufacturing hub for multiple industries.Paragraph 2:Operating under the principles of Industry 4.0, the factory features cutting-edge automation technologies, enabling a seamless and efficient production process. Leveraging advanced robotics, machine learning algorithms, and real-time data analytics, the factory ensures a high level of precision and accuracy in the wire bonding process. This not only minimizes production defects and improves yield rates but also reduces production time, ultimately enhancing cost-effectiveness for customers.Paragraph 3:The Au Wire Bonding Factory's commitment to quality is reflected in its rigorous quality control measures. With an integrated quality management system, the facility continuously monitors production parameters, ensuring compliance with industry standards and specifications. Moreover, employing a comprehensive testing system, the factory guarantees the reliability and durability of wire bonds, meeting the stringent demands of modern electronic devices.Paragraph 4:Recognizing the importance of sustainability, the company has also incorporated environmentally friendly practices into the Au Wire Bonding Factory. Adhering to green manufacturing principles, the facility utilizes energy-efficient technologies, reducing its carbon footprint. Additionally, the factory implements waste management techniques, promoting responsible disposal and recycling of materials. These efforts collectively contribute to a more eco-conscious production process, aligning with global efforts towards sustainability.Paragraph 5:The impact of the Au Wire Bonding Factory goes beyond its impressive manufacturing capabilities. As an industry leader, the company is committed to fostering collaboration and innovation within the semiconductor community. To facilitate this, the factory includes a dedicated research and development center, attracting top talent to work on cutting-edge advancements in wire bonding techniques. By acting as a hub for collaboration, the facility aims to accelerate the pace of technology adoption and drive industry-wide progress.Conclusion:The inauguration of the Au Wire Bonding Factory represents a groundbreaking leap forward for the semiconductor industry. With its advanced manufacturing techniques, commitment to quality, and sustainability practices, the facility holds the potential to redefine wire bonding technology. As the industry moves towards more complex and miniature devices, this factory's capabilities will undoubtedly play a crucial role in meeting the growing demands of the global market. By combining innovation, efficiency, and reliability, the Au Wire Bonding Factory emerges as a key player in semiconductor manufacturing, setting new standards for the industry as a whole.

Key Insights on the Growing Popularity of Surface Mount Devices

Title: Innovative Surface Mount Device Revolutionizes Electronics IndustryIntroduction:In recent years, the electronics industry has witnessed a groundbreaking development in the form of Surface Mount Devices (SMDs), which have revolutionized the way electronic components are incorporated into circuit boards. This article focuses on the advancements made by a leading company, ABC Electronics, and their cutting-edge SMD technology. By eliminating the need for traditional through-hole components, ABC Electronics has streamlined manufacturing processes, reduced costs, and improved overall product performance.1. Overview of Surface Mount Devices:Surface Mount Devices (SMDs) refer to electronic components that are soldered directly onto circuit boards without the need for drilling holes. These components are significantly smaller and lighter than their through-hole counterparts, allowing for more compact and efficient designs. SMD technology has transformed the landscape of the electronics industry by enhancing performance, reliability, and manufacturability.2. ABC Electronics: Pioneers in SMD Technology:ABC Electronics, a renowned industry leader, has spearheaded the development of SMD technology and its integration into various electronic devices. With years of research and innovation, ABC Electronics has successfully created a wide range of SMDs that meet the industry's requirements for smaller, more reliable, and high-performance electronic components.3. Advantages of SMDs:3.1 Miniaturization and Increased Component Density:The key advantage of SMD technology is its ability to significantly reduce the size of electronic components. This miniaturization allows for higher component density on circuit boards, enabling increased functionality without compromising on space.3.2 Enhanced Performance:SMDs offer improved electrical performance due to their shorter lead paths, reduced inductance, and capacitance. This results in faster signal propagation, reduced noise interference, and improved overall stability and reliability of electronic devices.3.3 Cost-Effectiveness:The manufacturing process for SMDs is highly automated, reducing labor costs associated with manual through-hole component assembly. Additionally, their compact size allows for efficient use of materials, contributing to overall cost savings during production.4. ABC Electronics' Innovative SMD Solutions:4.1 SMD Resistors, Capacitors, and Inductors:ABC Electronics has developed an extensive range of SMD resistors, capacitors, and inductors that surpass traditional through-hole components in terms of performance and footprint. These components offer high-precision values, tight tolerances, and improved temperature stability, enhancing the overall functionality of electronic devices.4.2 SMD Integrated Circuits (ICs):ABC Electronics' SMD ICs provide significant advancements in power management, signal processing, and wireless communication. With their miniaturized form factor, these ICs enable the creation of smaller and more powerful electronic devices for various applications, from smartphones to medical equipment.4.3 SMD Connectors and Switches:ABC Electronics has also engineered SMD connectors and switches that offer reliable electrical connections in compact spaces. Incorporating advanced contact materials and designs, these connectors and switches provide excellent durability and performance while reducing assembly time and costs.5. Future Developments and Market Impact:The emergence of SMD technology has sparked a wave of innovation within the electronics industry. With ongoing research and development, ABC Electronics and other industry players aim to push the boundaries of miniaturization, performance, and reliability even further. As the demand for smaller and more powerful electronic devices continues to grow, SMDs are predicted to play a crucial role in shaping the future of technology.Conclusion:Surface Mount Devices have undoubtedly transformed the electronics industry, and ABC Electronics stands at the forefront of this revolution. Through their innovative SMD technology, ABC Electronics has enabled enhanced performance, reduced production costs, and accelerated the pace of technological advancements. As electronics continue to evolve, SMDs will remain a key driving force, powering the next generation of devices and opening up endless possibilities for various industries.

Decoding the Latest Advancements in China's SMT Component Packages

**Title: China's SMT Component Packages: Quality-oriented Manufacturing Excellence***Note: The brand name has been intentionally removed as per your request.**Date: [Enter Date]**Location: [Enter Location]*China's SMT component package industry has witnessed remarkable growth in recent years, owing to the country's continuous efforts towards manufacturing excellence. Several Chinese companies have emerged as key players in the global electronic components market, focusing on technological advancements, quality improvements, and meeting evolving market demands. Among these companies, [Enter Company Name] has been a prominent figure, making significant contributions to the sector's development.Founded in [Enter Year], [Enter Company Name] has established itself as a leading manufacturer of SMT (Surface Mount Technology) component packages in China. The company's unwavering commitment to delivering high-quality products and exceptional customer service has earned it a strong reputation both domestically and internationally.[Enter Company Name]'s state-of-the-art facilities and cutting-edge manufacturing techniques enable them to produce an extensive range of SMT component packages. From resistors, capacitors, and inductors to various integrated circuits, connectors, and diodes; the company offers a comprehensive portfolio of solutions catering to diverse applications across industries.Quality assurance is at the heart of [Enter Company Name]'s operations. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that each component package meets or exceeds industry standards. By utilizing advanced testing equipment and employing a highly skilled workforce, they are able to consistently deliver products of exceptional quality and reliability.In addition to quality, [Enter Company Name] places great importance on research and development. With a dedicated team of engineers and technicians, the company focuses on innovation and the continuous improvement of its product offerings. By staying up-to-date with the latest technological advancements and market trends, they strive to provide SMT component packages that meet the evolving needs of their global clientele.Furthermore, [Enter Company Name] recognizes the significance of sustainable manufacturing practices. The company has adopted eco-friendly production methods, reducing its environmental impact and promoting a greener future. By implementing energy-saving technologies and minimizing waste generation, they demonstrate their commitment towards corporate social responsibility.[Enter Company Name]'s efforts have not gone unnoticed. The company has received several accolades for its contribution to the SMT component package industry. They have been recognized for their outstanding quality management systems, technological advancements, and sustainable practices. These achievements reinforce their position as a trusted supplier with a focus on excellence in every aspect of their operations.Internationally, [Enter Company Name] has built a strong distribution network, ensuring efficient and timely deliveries to customers across the globe. The company's export-oriented approach has enabled it to establish strong partnerships with clients from diverse industries, including automotive, telecommunications, consumer electronics, and medical devices.Looking ahead, [Enter Company Name] remains committed to innovation and continuous improvement. The company plans to further expand its manufacturing capabilities, invest in advanced technologies, and strengthen its research and development efforts. With a clear vision for the future and a commitment to excellence, [Enter Company Name] is poised to lead China's SMT component package industry towards further growth and success.In conclusion, China's SMT component package industry continues to flourish, driven by companies like [Enter Company Name]. With a focus on quality, innovation, and sustainability, [Enter Company Name] has established itself as a key player in the global market. As they strive to meet evolving market needs and maintain manufacturing excellence, China's SMT component package industry is well-positioned to contribute significantly to the electronics sector's growth in the years to come.

Optimizing Your Business with Efficient PCB Assembly Services

Title: Leading Electronics Manufacturer Expands Services with Advanced PCB Assembly Solutions[City], [Date] - In a strategic move to bolster its comprehensive range of electronic manufacturing services, [], one of the industry-leading electronics manufacturers, is now offering advanced consigned PCB assembly solutions. The company aims to seamlessly integrate its state-of-the-art production facilities with customer-supplied materials to provide highly efficient and cost-effective PCB manufacturing services.The addition of consigned PCB assembly services is a natural progression for [], which has established itself as a trailblazer in the electronics manufacturing industry. With over [number of years] of experience, the company has earned a reputation for delivering top-quality, innovative electronic products.[] specializes in delivering complete turnkey solutions, offering a wide array of services including design, manufacturing, assembly, and testing. By expanding its offerings to include consigned PCB assembly, the company seeks to cater to a wider customer base and better fulfill its mission of delivering tailored solutions to meet the unique needs of each client.Consigned PCB assembly involves collaborating with customers who provide the necessary materials, components, and components' assembly instructions. The specialized team at [] will then utilize their expertise and state-of-the-art equipment to assemble the PCBs according to the clients' specifications. This highly flexible approach enables customers to retain complete control over their supply chain and product quality, ensuring that their unique design requirements are met.With its cutting-edge manufacturing facilities and a team of highly skilled professionals, [], allows customers to leverage its extensive technical expertise and resources, thereby enhancing their overall operational efficiency. The company's commitment to quality, reliability, and innovation makes it the perfect partner for organizations seeking to outsource their PCB assembly requirements.By offering consigned PCB assembly services, [] opens up new avenues for companies looking to streamline their manufacturing processes. This strategic move enables clients to focus on their core competencies while relying on [] to handle the complexities of component sourcing, quality control, and manufacturing. This not only saves valuable time and resources but also ensures shorter lead times and faster go-to-market capabilities for the customers.The consigned PCB assembly services offered by [] adhere to the highest industry standards. The company employs a rigorous Quality Management System that covers every aspect of the manufacturing process, ensuring that each PCB assembly is meticulously inspected and tested for functionality, reliability, and durability.Moreover, [], as an environmentally responsible organization, implements eco-friendly manufacturing practices. The company complies with all relevant regulations and is committed to reducing its carbon footprint by employing efficient manufacturing techniques, recycling waste materials, and ensuring the responsible disposal of hazardous substances.With its new consigned PCB assembly services, [] is poised to reinforce its position as a preferred partner for companies seeking comprehensive electronic manufacturing solutions. The company's ability to scale production based on demand, combined with its commitment to quality and innovative design, ensures that clients receive a competitive edge in the market.To learn more about the advanced consigned PCB assembly services offered by [], visit their website at [website URL].About []:[] is a prominent electronic manufacturing services provider known for its commitment to delivering reliable and innovative solutions. With state-of-the-art facilities and a team of highly skilled professionals, the company offers a comprehensive range of services including PCB design, manufacturing, assembly, and testing. Drawing upon their industry expertise, [] strives to exceed customer expectations by delivering exceptional quality, flexibility, and value.For media inquiries, please contact:[Contact Name][Title][Company Name][Email Address][Phone Number]