- Home

- Chip On Board Wire Bonding

Reliable Chip On Board Wire Bonding Manufacturer in China for Wholesale Export

Introducing the latest innovation in electronic packaging technology - Chip On Board Wire Bonding, brought to you by Zhuhai Xinrunda Electronics Co., Ltd., a leading manufacturer, supplier, and factory based in China.

Chip On Board Wire Bonding revolutionizes the way electronic components are assembled, offering enhanced functionality and superior performance. By integrating the chips directly onto the substrate, our advanced wire bonding technique ensures secure and reliable connections, resulting in reduced signal loss and increased overall efficiency.

With our cutting-edge manufacturing facility and state-of-the-art equipment, Xinrunda Electronics Co., Ltd. employs a highly skilled team of experts dedicated to delivering high-quality products. Our Chip On Board Wire Bonding technology caters to a diverse range of electronic applications, including telecommunications, consumer electronics, automotive, and industrial sectors.

Experience the difference that Chip On Board Wire Bonding can make in your product development process. With its compact design and excellent thermal management capabilities, it opens doors to new possibilities in miniaturization and integration. Trust in Xinrunda Electronics Co., Ltd. to provide you with innovative solutions that drive your business forward. Contact us today to learn more about our superior products and services.

Zhuhai Xinrunda Electronics Co,. Ltd.

Company News

Related News

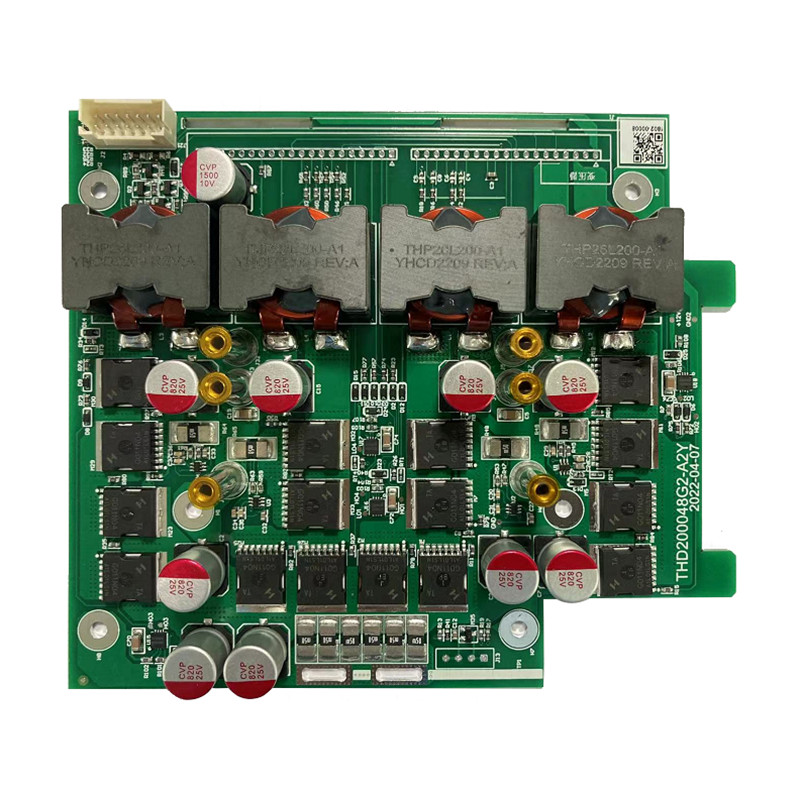

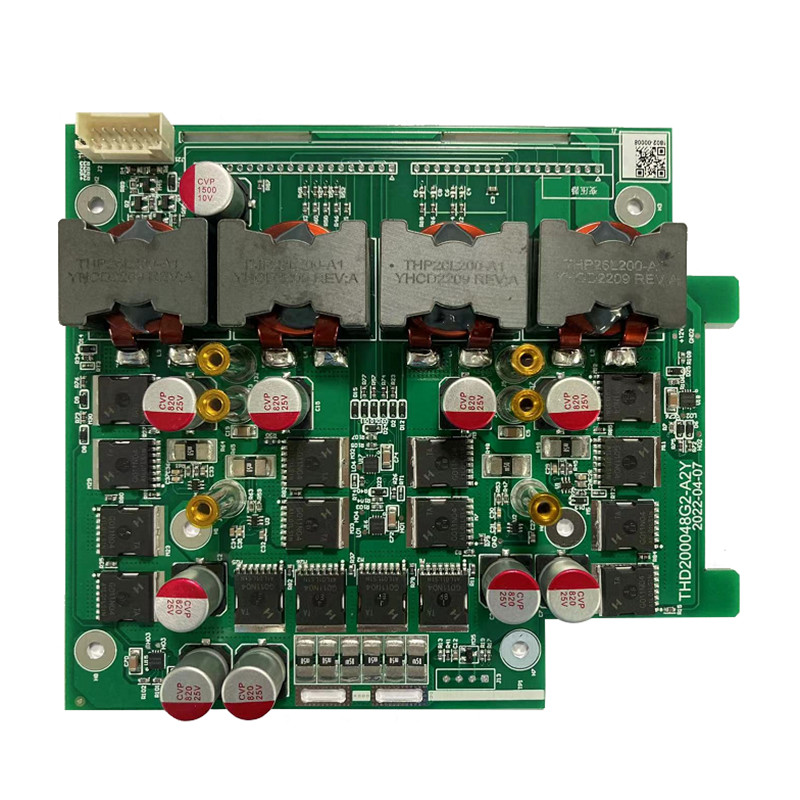

Electrical & Power PCB Assembly Service

Looking for professional Electrical & Power PCB Assembly Service? Look no further! We are a factory specializing in top-quality assembly solutions.

Medical PCB Assembly Service

Looking for reliable Medical PCB Assembly Service? Look no further! We are a factory offering top-notch assembly solutions for medical device manufacturers.

Automotive PCB Assembly Service

Looking for top-notch Automotive PCB Assembly Service? Look no further! We are a factory specializing in high-quality assembly, guaranteeing reliability and efficiency.

Industrial Instrument PCB Assembly Service

Looking for reliable industrial instrument PCB assembly service? Look no further! We are a dedicated factory, offering high-quality PCB assembly solutions.

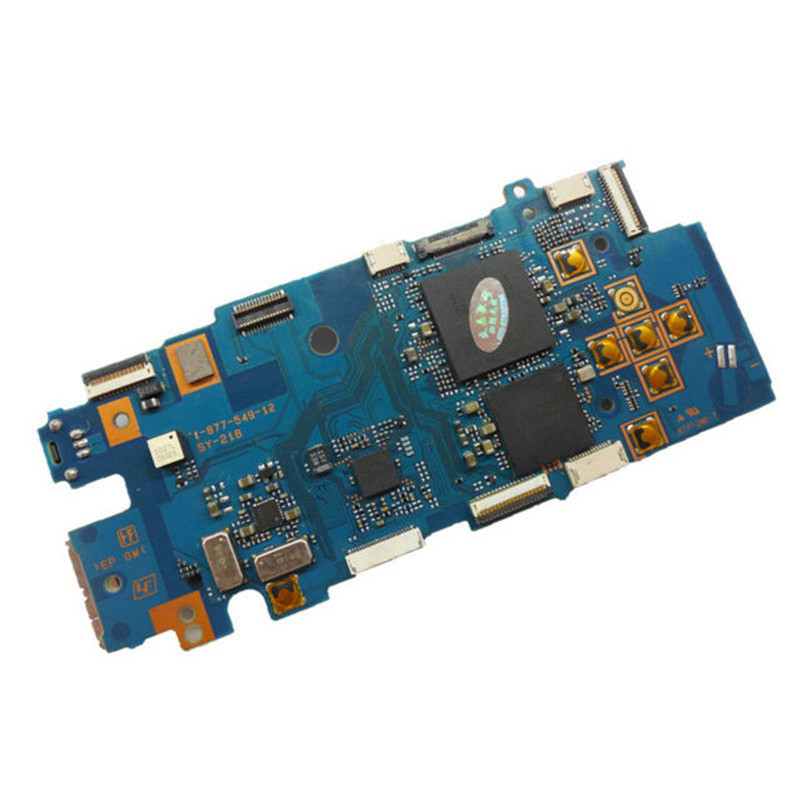

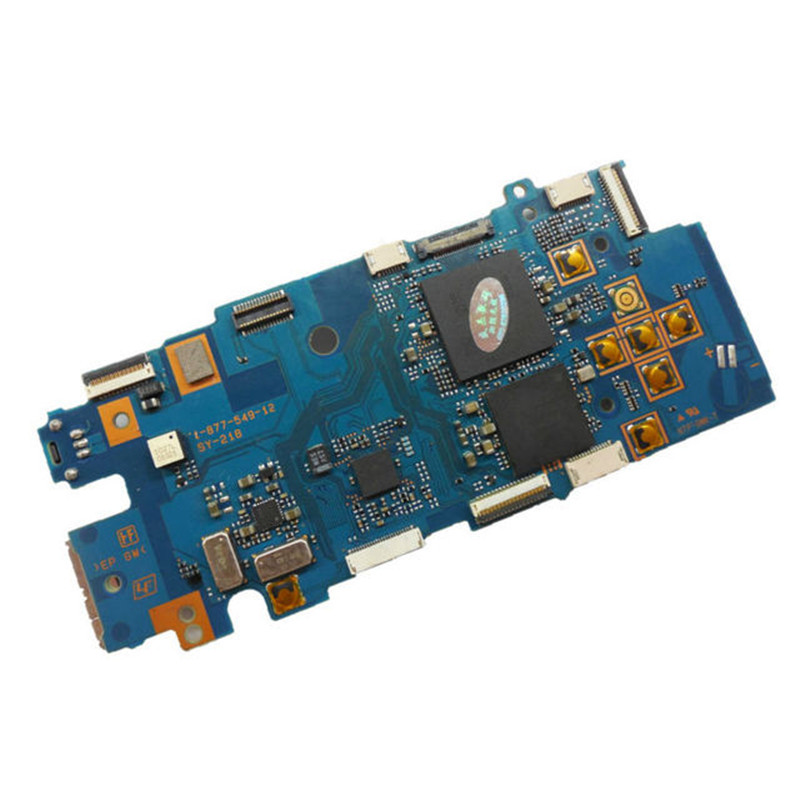

Phone Electronics PCB Assembly Service

Get high-quality phone electronics PCB assembly service from our factory. We specialize in efficient production processes to ensure top-notch products.

Communication PCB Assembly Service

Get top-notch Communication PCB Assembly Service from our factory. We offer reliable and efficient solutions for all your communication circuit board needs. Contact us now!

New Energy PCB Assembly Service

Looking for a reliable factory offering top-notch New Energy PCB Assembly Service? Look no further! Trust our expertise and experience for all your electronic manufacturing needs.

Automated Products PCB Assembly Service

Get high-quality PCB assembly service for your automated products from our factory. We specialize in efficient and cost-effective manufacturing solutions.

Intelligent Digital PCB Assembly Service

Experience seamless Intelligent Digital PCB Assembly Service with our factory. Trust us for reliable, precise and efficient manufacturing solutions.

Artificial Intelligence PCB Assembly Service

Experience top-notch AI PCB assembly services at our factory. We offer advanced technology and expertise for efficient production and high-quality products.

Consumer Electronics PCB Assembly Service

We are a leading factory offering top-notch Consumer Electronics PCB Assembly Service. Count on our expertise and quality for all your assembly needs.

One-Stop PCB Assembly Service

One-Stop PCB Assembly Service - Simplify your production process with our factory-direct solution. Get high-quality PCB assembly done efficiently at competitive prices.

Lfestyle Equipment PCB Assembly Service

Choose our Lifestyle Equipment PCB Assembly Service! We are a factory specializing in high-quality electronic assembly. Trust us for efficient and reliable production.

- Top Chip On Board Wire Bonding Manufacturer in China - Wholesale Supplier

- Reviews

- Related Videos

Introducing our revolutionary and cutting-edge product, the Chip On Board Wire Bonding solution. Designed to revolutionize the electronics industry, our innovative technology brings unprecedented advantages to chip packaging and wire bonding processes. At the heart of our product lies our state-of-the-art Chip On Board (COB) technology, which allows for efficient and reliable bonding of wires directly onto a semiconductor chip. This groundbreaking solution eliminates the need for conventional packaging techniques, resulting in a compact and lightweight design that enhances device performance. Our COB Wire Bonding solution offers numerous benefits that set it apart from traditional methods. By eliminating the need for bulky packaging, our product drastically reduces the overall size and weight of electronic devices, making it ideal for applications where space is at a premium. Additionally, the direct wire bonding technique ensures superior electrical performance and enhances signal transmission, resulting in devices that operate at optimal efficiency. Our product also addresses the challenges of thermal management in electronic devices. With our COB Wire Bonding technology, chips are mounted directly onto a substrate, maximizing heat dissipation and minimizing thermal resistance. This prevents overheating issues and enhances the reliability and lifespan of the device, even under demanding conditions. Furthermore, our COB Wire Bonding solution offers increased manufacturing efficiency and cost-effectiveness. With its simplified packaging process and reduced material requirements, manufacturers can streamline their production lines and reduce production costs, ultimately providing end-users with cost-effective electronic devices. In conclusion, our Chip On Board Wire Bonding solution redefines chip packaging and wire bonding processes. With its compact design, enhanced electrical performance, improved thermal management, and cost-effectiveness, our product enables the development of smaller, more efficient, and reliable electronic devices. Stay ahead in the electronics industry by incorporating our innovative COB Wire Bonding solution into your manufacturing process.

Chip On Board (COB) wire bonding is a revolutionary technology that has completely transformed the electronics industry. With COB, the days of bulky circuit boards and messy wiring are long gone. This advanced method involves directly bonding the microchips onto the board, resulting in compact and efficient devices. The benefits of COB wire bonding are manifold. Firstly, it offers enhanced durability, shielding the delicate components from external damages. Secondly, the compactness of COB eliminates the need for additional connectors, resulting in a simplified design and reduced costs. Lastly, the direct bonding process ensures improved electrical performance and signal integrity. In terms of functionality, COB wire bonding delivers exceptional results. Whether it's in smartphones, smartwatches, or even automotive electronics, the technology ensures optimal performance and reliability. The seamless integration of the chips enables faster data transfer, precise control, and improved power efficiency. Overall, COB wire bonding is a game-changer in the electronics industry. It combines the advantages of miniaturization, durability, and efficiency, making it a highly recommended choice for any electronic device manufacturer. With COB, you can expect a seamless user experience and high-quality performance, revolutionizing the way we interact with technology.

The Chip On Board Wire Bonding technology is truly revolutionary. This advanced technique enables the miniaturization of electronic components, resulting in smaller and more efficient products. I recently purchased a device that utilized this technology, and I have been thoroughly impressed. The wire bonding process ensures excellent electrical connectivity and reliability. The compact size of the product is incredible, making it extremely portable and convenient. Additionally, the improved thermal management enhances the device's performance and prolongs its lifespan. Overall, chip on board wire bonding is a game-changer in the electronics industry, delivering superior functionality in smaller packages. I highly recommend products using this technology for their outstanding performance and compact design.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours